Large-area ultrathin single crystal and rapid growth method thereof

A crystal growth and single crystal technology, applied in the field of materials, can solve problems such as uneven concentration, high growth temperature, and long growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

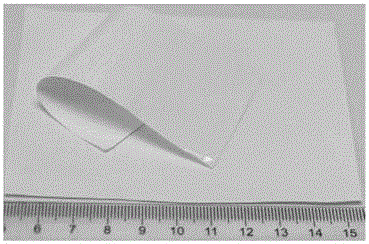

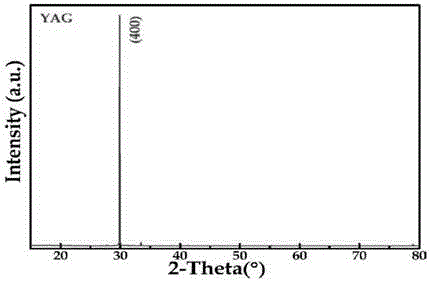

[0056] According to Ce 3+ : The molar ratio of YAG phosphor (particle size: 10μm) to YAG (particle size: 10μm) is 1:12, accurately weigh 7.7305gCe 3+ : YAG, 53.1404g Y 2 o 3 , 39.8088g Al 2 o 3 , 24.7865g ethanol, 37.1797g xylene, 3.9653g fish oil, 0.3726g tetraethyl orthosilicate and 0.0791g MgO (0.5μm particle size) powder, ball mill the weighed powder for 24h, then add 5.9480g PVB , 0.7435g n-butanol, 2.9740g butyl benzyl phthalate ball milled for 24 hours. The ball-milled slurry is flow molded to obtain a flow mold sheet with a thickness of about 0.15mm, and the laminated two-layer isostatically pressed (temperature 120°C, pressure 8Mpa, holding time 3min), and then in an oxygen atmosphere at 0.5°C / min After the heating rate is raised to 700 ° C for 10 hours of thermal decomposition (that is, the degreasing step), in a vacuum of 10 -4 Pa, grown at 1800°C for 2 hours, and then cooled down to room temperature at a cooling rate of 1°C / min to obtain a yellow single cryst...

Embodiment 2

[0061] According to Eu 3+ :Y 2 o 3 (Particle size is 10μm) phosphor and Y 2 o 3 (particle size 15μm) molar ratio 1:2, accurately weigh 10gEu 3+ :Y 2 o 3 , 19.8367g Y 2 o 3 , 8.7843g ethanol, 13.1765g xylene, 1.7177g fish oil, 0.1353g tetraethyl orthosilicate, mill the weighed powder for 24 hours, then add 2.5765g PVB, 0.3971g n-butanol, 0.9882g phthalic acid Butylbenzyl ester was ball milled for 24 hours. The ball-milled slurry is flow molded to obtain a flow mold sheet with a thickness of about 0.15mm, and the two layers of the laminate are isostatically pressed (temperature 120°C, pressure 4Mpa, holding time 3min), and then in an oxygen atmosphere at 0.5°C / min After the heating rate is raised to 700 ° C for 10 hours of thermal decomposition (that is, the degreasing step), in a vacuum of 10 -4 Pa, grown at 1880°C for 5 hours, and then cooled down to room temperature at a cooling rate of 5°C / min to obtain a red single crystal sheet with a thickness of 0.25mm and a di...

Embodiment 3

[0063] According to Mn 2+ :MgAl 2 o 4 Phosphor powder (particle size 10μm) and MgAl 2 o 4 (particle size 10μm) molar ratio 1:1, accurately weigh 14.2563g Mn 2+ :MgAl 2 o 4 , 4.8367g MgO, 10.8279g Al 2 o 3 , 7.7841g ethanol, 11.1765g xylene, 0.7172g fish oil, 0.1154g tetraethyl orthosilicate, mill the weighed powder for 24 hours, then add 2.0763g PVB, 0.1972g n-butanol, 0.8882g phthalic acid Butylbenzyl ester was ball milled for 24 hours. The ball-milled slurry is flow molded to obtain a flow mold sheet with a thickness of about 0.15mm, and the laminated two-layer isostatically pressed (temperature 120°C, pressure 8Mpa, holding time 3min), and then in an oxygen atmosphere at 0.5°C / min After the heating rate is raised to 700°C for 10 hours of thermal decomposition (that is, the degreasing step), it grows in a nitrogen atmosphere of 0.5Mpa and a temperature of 1830°C for 2 hours, and then cools down to room temperature at a cooling rate of 1°C / min to obtain a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com