Synthesis method of mesoporous zeolite

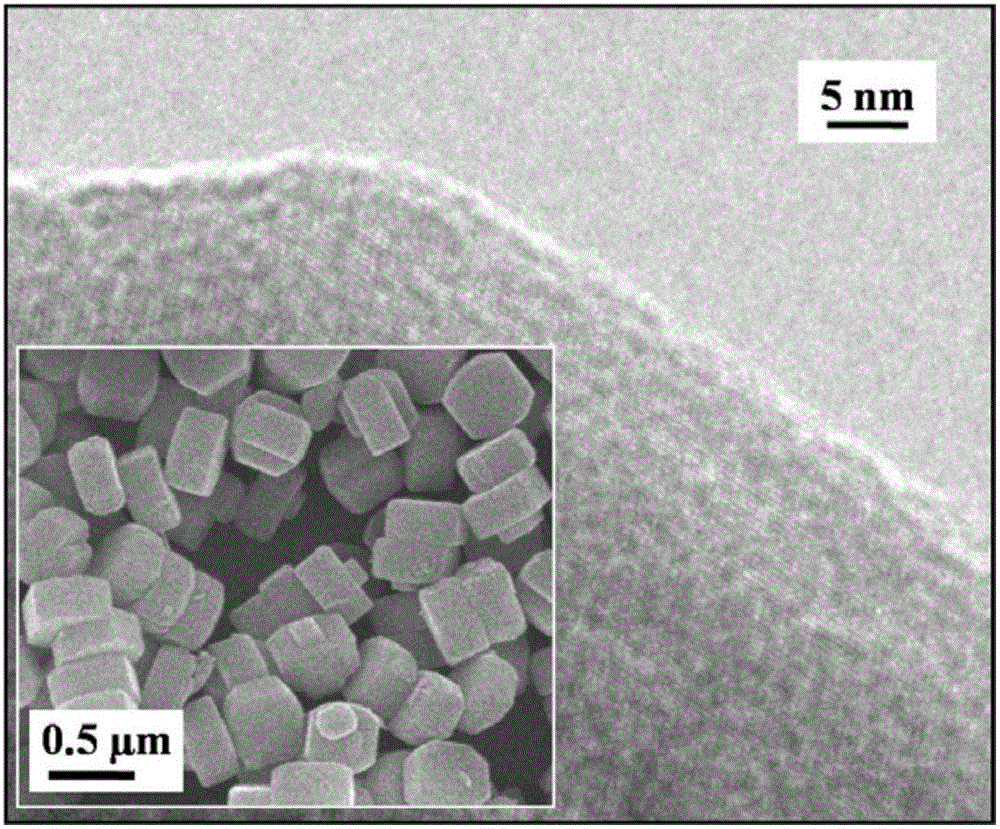

A mesoporous zeolite and zeolite technology, applied in the field of synthetic mesoporous zeolite, can solve the problems of uneven mesoporous distribution, wide pore size distribution range, and large destructive crystal structure, and achieve excellent performance and narrow pore size distribution range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 25 mg of SWCNHs and add it into ethanol for ultrasonic dispersion. In another reaction vessel was added 16mg NaOH, 4mL H 2 O and 1.2mL TPAOH, stirred by magnetic force, poured the dispersed SWCNHs into the reaction solution, stirred continuously to volatilize the ethanol until the ethanol was completely volatilized, then added 1.117mL TEOS. Stir at room temperature, age for 10 h, then transfer the reaction mixture into a polytetrafluoroethylene-lined hydrothermal reactor, and perform hydrothermal synthesis reaction at 150° C. for 5 days. After the completion of the synthesis reaction, centrifugation, washing, drying, and finally calcination at 600 ° C to remove SWCNHs to obtain Silicate-1 zeolite containing mesoporous.

Embodiment 2

[0035] Weigh 100mg of SWCNHs into ethanol and ultrasonically disperse. In another reaction vessel was added 4 mL of H 2 O and 1.2mL TPAOH, magnetically stirred, poured the dispersed SWCNHs into the reaction solution, and kept stirring to volatilize the ethanol until the ethanol was completely volatilized, then added 1.117mL TEOS. Stir at room temperature, age for 10 h, transfer the reaction mixture into a polytetrafluoroethylene-lined reactor, and perform hydrothermal synthesis at 180° C. for 2 days. After the synthesis reaction is finished, it is centrifuged, washed, dried, and finally calcined at 600° C. to remove SWCNHs to obtain Silicate-1 zeolite containing mesoporous pores.

Embodiment 3

[0037] Weigh 50mg of SWCNHs into ethanol and ultrasonically disperse. In another reaction vessel was added 4 mL of H 2O and 1.2mL TPAOH, magnetically stirred, poured the dispersed SWCNHs into the reaction solution, and stirred continuously to volatilize the ethanol until the ethanol was completely volatilized, then added 1.117mL TEOS. Stir at room temperature, age for 10 h, transfer the reaction mixture into a polytetrafluoroethylene-lined hydrothermal reactor, and perform a hydrothermal synthesis reaction at 180° C. for 2 days. After the synthesis reaction is finished, it is centrifuged, washed, dried, and finally calcined at 600° C. to remove SWCNHs to obtain Silicate-1 zeolite containing mesoporous pores.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com