Preparation method of mesoporous silica thin film material with low dielectric constant

A technology of mesoporous silicon oxide and low dielectric constant, applied in the field of nano-materials, achieves the effects of high temperature thermal stability and hydrophobic stability, good adhesion performance, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

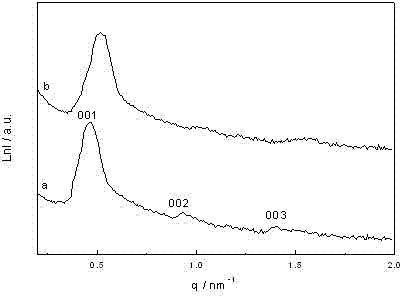

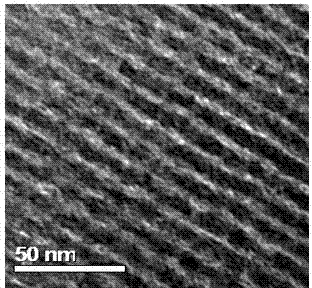

[0030] Example 2 The small-angle X-ray scattering (SAXS) measurement of the silicon oxide film material obtained in Example 1 was carried out by using the Nanostar U small-angle X-ray scattering instrument (CuKα) of Bruker, Germany. The tube pressure was 40 kV, the tube flow was 35 mA, and the recording time was 30 min. The resulting SAXS as figure 1 shown. Depend on figure 1 It can be seen that the SAXS spectra of As-made samples are at 0.46, 0.93 and 0.39 nm -1 3 clear diffraction peaks appear at , the three diffraction peaks q The value ratio is 1:2:3, which is assigned as the crystal plane diffraction peak of the layered mesoporous structure. After roasting under the protection of nitrogen at 350 °C, the clarity of the SAXS spectrum of the obtained sample decreased, and the diffraction peaks became wider, but two obvious diffraction peaks could also be observed, indicating that the layered structure after roasting at 350 °C still maintains the mesoporous structure. ...

Embodiment 2

[0033] Example 5 Use a contact angle measuring instrument (JC 2000A Powereach) to characterize the hydrophobic properties of the mesoporous silicon oxide thin layer obtained in Example 1, and use the formula for the contact angle Calculate, where h is the height of the water droplet, and d is the width of the thin layer in contact with the water droplet. Depend on Figure 4 It can be calculated that the hydrophobic angle of the measured mesoporous thin film material is 110.3°, which shows that the obtained thin layer material has excellent hydrophobic performance and good hydrophobic stability.

Embodiment 3

[0034] Embodiment 6 For the measurement of the dielectric constant, HP 4284A precision LCR meter is used for measurement. The quantum dots have a diameter of 3 mm and a frequency of 1 MHz. The dielectric constant is calculated from the capacitance and the area of the metal electrodes. Depend on Figure 5 It can be seen that the dielectric constant of the mesoporous silicon oxide film material after firing is 2.26, and the stable time of the dielectric properties can be as long as 20 days. The excellent dielectric properties of mesoporous silicon oxide thin layers can be attributed to its ordered mesoporous structure and excellent hydrophobic properties. Under room temperature conditions, the dielectric constant increased by 0.26 after 20 days, which was only 11.5%, indicating that the silicon oxide thin film material prepared in Example 1 had good dielectric stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com