Method for treating aluminum-containing waste emulsion

A treatment method, biochemical treatment technology, applied in the direction of metallurgical wastewater treatment, chemical instruments and methods, multi-stage water treatment, etc., can solve the problem of low quality sewage, no mention of the treatment method of aluminum-containing emulsified waste liquid, and poor wastewater treatment Thoroughness and other issues, to achieve the effect of sequence layout optimization, water treatment cost reduction, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

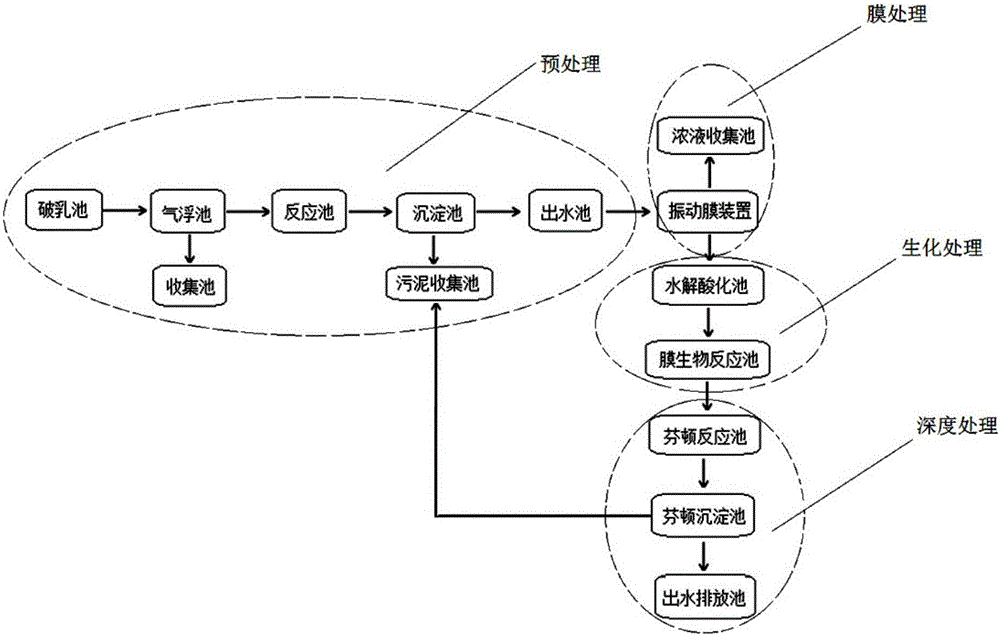

[0030] The aluminum-containing emulsified waste liquid discharged from a certain workshop has a COD of 100,000mg / L, an aluminum chip of 4g / L, and an oil concentration of 12-15wt%. The waste liquid is treated according to the method of the present invention, and the treatment capacity is 15t / d , the schematic diagram of the process flow is shown in figure 1 As shown, the specific steps are:

[0031] (1) Pretreatment: inject the aluminum-containing emulsified waste liquid into the demulsification tank, add non-ionic demulsifier and sulfuric acid, stir until the aluminum chips are completely dissolved, and adjust the pH in the demulsification tank to 5; inject the effluent from the demulsification tank into the air flotation tank , collect the upper oil slick into the collection tank, inject the lower liquid into the reaction tank, and control the pH in the reaction tank at 8-10; add sodium hydroxide into the reaction tank; the effluent from the reaction tank enters the sedimenta...

Embodiment 2

[0037] The aluminum-containing emulsified waste liquid discharged from a processing workshop has a COD of about 30,000mg / L, an aluminum scrap of about 2g / L, and an oil concentration of about 6%. Adopt the inventive method to process this waste liquid, the processing capacity is 10t / d, and concrete steps are:

[0038] (1) Pretreatment: inject the aluminum-containing emulsified waste liquid into the demulsification tank, add non-ionic demulsifier and hydrochloric acid, stir until the aluminum chips are completely dissolved, and adjust the pH in the demulsification tank to 3; inject the effluent from the demulsification tank into the air flotation tank , collect the upper floating oil to the collection tank, inject the lower clear liquid into the reaction tank, and adjust the pH in the reaction tank to 9; add sodium hydroxide into the reaction tank; the effluent from the reaction tank enters the sedimentation tank, and the sediment in the sedimentation tank is collected into the s...

Embodiment 3

[0044] An aluminum-containing emulsified waste liquid has an aluminum content of 3 mg / L, an emulsified oil content of 8 wt%, and a chemical oxygen demand of 80,000 mg / L. The waste liquid is treated by the method of the present invention, and the specific steps are as follows:

[0045] (1) Pretreatment: inject the aluminum-containing emulsified waste liquid into the demulsification tank, add non-ionic demulsifier and sulfuric acid, stir until the aluminum chips are completely dissolved, and adjust the pH in the demulsification tank to 2; inject the effluent from the demulsification tank into the air flotation tank , collect the upper oil slick into the collection tank, inject the lower liquid into the reaction tank, and control the pH in the reaction tank at 9; add sodium hydroxide into the reaction tank; the effluent from the reaction tank enters the sedimentation tank, and the sediment in the sedimentation tank is collected into the sludge The collection tank, the supernatant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com