Carbon fiber reinforced cement-based composite for 3D printing technology

A technology for strengthening cement and composite materials, applied in the field of 3D printing materials, it can solve problems such as poor fluidity, high brittleness, and self-weight, and achieve the effect of improving mechanical properties, high strength, and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take the production of a pitch-based carbon fiber reinforced cement-based composite material as an example. The composition ratio of the calcium sulfoaluminate modified Portland cement in this example is: 70.5% limestone; 12.5% aluminum ore tailings; 1.0% sandstone; 6.5% industrial waste gypsum; 9.5% fly ash.

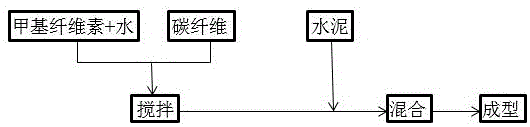

[0030] The preparation method of above-mentioned 3D printing material is:

[0031] Step 1. Dissolve methylcellulose accounting for 0.6% of the cement mass in warm water, stir evenly for 2-3 minutes to disperse it, and then add chopped asphalt accounting for 2.0% of the total volume of the carbon fiber reinforced cement-based composite material base carbon fiber, continue to stir evenly for 3-4 minutes;

[0032] Step 2, preparing calcium sulfoaluminate modified Portland cement according to the mass ratio of the components of the above cement-based matrix;

[0033] Step 3: Mix uniformly stirred carbon fiber and methyl cellulose with calcium sulfoaluminate modif...

Embodiment 2

[0035] Take the production of a pitch-based carbon fiber reinforced cement-based composite material as an example. The composition ratio of the calcium sulfoaluminate modified Portland cement in this example is: limestone 71.5%; aluminum ore tailings 11.5%; sandstone 0.5%; industrial waste gypsum 6.5%; fly ash 10.5%.

[0036] The preparation method of above-mentioned 3D printing material is:

[0037] Step 1. Dissolve methyl cellulose accounting for 0.6% of the cement mass in warm water, stir evenly for 2-3 minutes to disperse it, and then add chopped asphalt accounting for 4.0% of the total volume of the carbon fiber reinforced cement-based composite material base carbon fiber, continue to stir evenly for 3-4 minutes;

[0038] Step 2, preparing calcium sulfoaluminate modified Portland cement according to the mass ratio of the components of the above cement-based matrix;

[0039] Step 3: Mix uniformly stirred carbon fiber and methyl cellulose with calcium sulfoaluminate modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com