Plastic packaging bag and method for preparing same

A packaging bag and plastic technology, applied in the field of plastic products, can solve problems such as inadequate use and recycling, ecological environment damage, and inability to degrade, and achieve good economic benefits, low cost, and good degradation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

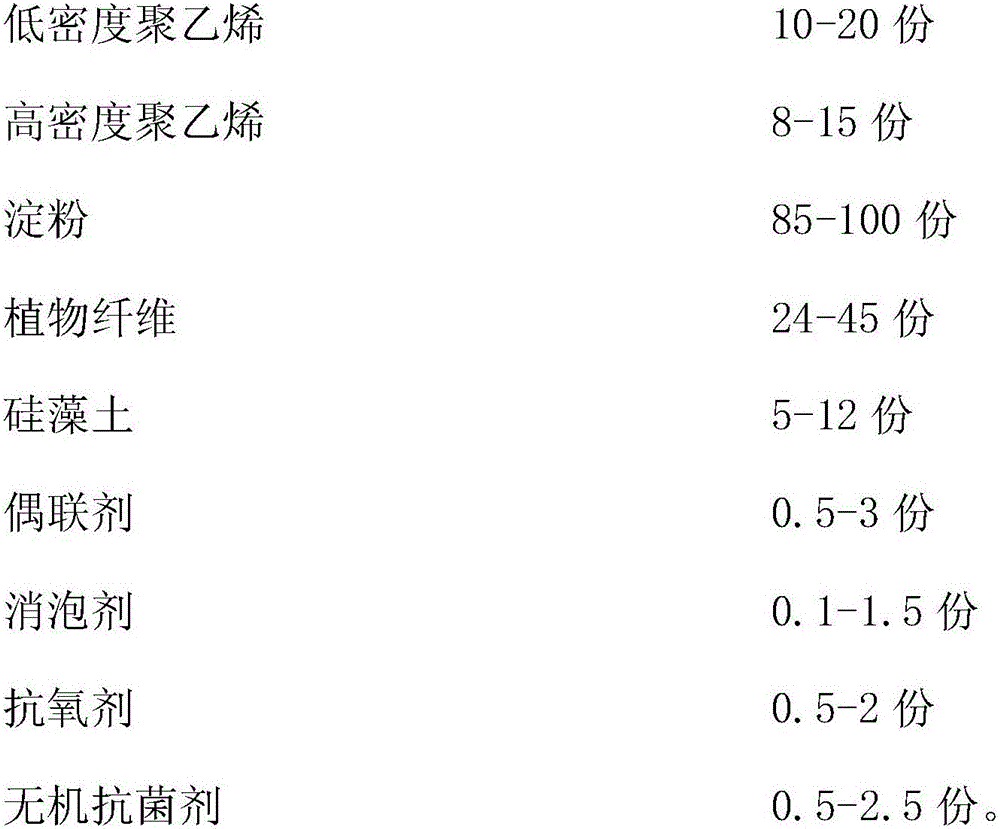

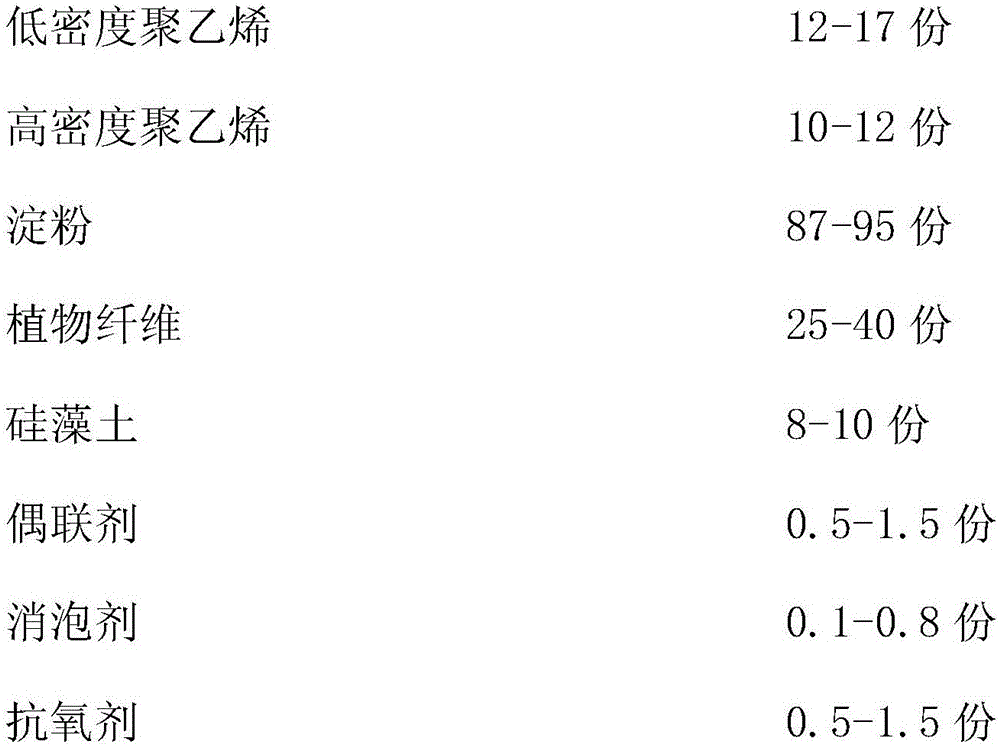

[0023] A plastic packaging bag is composed of the following raw materials in parts by weight: 10 parts of low-density polyethylene, 8 parts of high-density polyethylene, 85 parts of starch, 24 parts of plant fiber, 5 parts of diatomaceous earth, 0.5 parts of coupling agent, disinfectant 0.1 part of foaming agent, 0.5 part of antioxidant, 0.5 part of inorganic antibacterial agent; Wherein starch is the mixture of corn starch, potato starch and sweet potato starch, wherein the weight ratio of corn starch, potato starch and sweet potato starch is 1:3:1.2; The plant fiber is one of straw fiber, bagasse fiber or bamboo wood fiber; the coupling agent is a titanate coupling agent; the defoamer is one of emulsified silicone oil or high-carbon alcohol fatty acid ester compound; The antibacterial agent is a composite antibacterial agent loaded with silver montmorillonite.

[0024] A preparation method for a plastic packaging bag, specifically comprising the following steps:

[0025] We...

Embodiment 2

[0027] A plastic packaging bag is composed of the following raw materials in parts by weight: 20 parts of low-density polyethylene, 15 parts of high-density polyethylene, 100 parts of starch, 45 parts of plant fiber, 12 parts of diatomaceous earth, 3 parts of coupling agent, disinfectant 1.5 parts of foaming agent, 2 parts of antioxidant, 2.5 parts of inorganic antibacterial agent; Wherein starch is the mixture of corn starch, potato starch and sweet potato starch, wherein the weight ratio of corn starch, potato starch and sweet potato starch is 1:3:1.2; The plant fiber is one of straw fiber, bagasse fiber or bamboo wood fiber; the coupling agent is a titanate coupling agent; the defoamer is one of emulsified silicone oil or high-carbon alcohol fatty acid ester compound; The antibacterial agent is a composite antibacterial agent loaded with silver montmorillonite.

[0028] A preparation method for a plastic packaging bag, specifically comprising the following steps:

[0029] ...

Embodiment 3

[0031] A plastic packaging bag is composed of the following raw materials in parts by weight: 15 parts of low-density polyethylene, 12 parts of high-density polyethylene, 90 parts of starch, 30 parts of plant fiber, 9 parts of diatomaceous earth, 1 part of coupling agent, disinfectant 0.2 part of foaming agent, 0.5 part of antioxidant, 1.5 parts of inorganic antibacterial agent; Wherein starch is the mixture of corn starch, potato starch and sweet potato starch, wherein the weight ratio of corn starch, potato starch and sweet potato starch is 1:3:1.2; The plant fiber is one of straw fiber, bagasse fiber or bamboo wood fiber; the coupling agent is a titanate coupling agent; the defoamer is one of emulsified silicone oil or high-carbon alcohol fatty acid ester compound; The antibacterial agent is a composite antibacterial agent loaded with silver montmorillonite.

[0032] A preparation method for a plastic packaging bag, specifically comprising the following steps:

[0033] Wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com