PBT/PC alloy material and preparation method and application thereof

An alloy material, PBT6.5-42.6 technology, applied in the field of PBT/PC alloy material and its preparation, can solve the problems of insufficient product strength, cracking, and easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

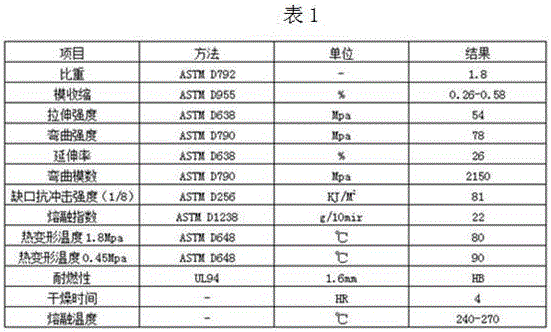

Embodiment 1

[0018] The present embodiment provides a kind of PBT / PC alloy material, and its raw material comprises by weight:

[0019] 31.2 copies of PBT;

[0020] PC 80 copies;

[0021] 0.5 part of transesterification inhibitor;

[0022] The raw materials of the transesterification inhibitor include by weight 2 parts of aluminum silicate, 0.03 part of diethanol monoisopropanolamine, 0.7 part of sodium lauryl sulfate, 3 parts of copper hydroxide, 0.2 part of sodium citrate, 0.07 Parts of fluoroantimonysulfonic acid.

[0023] The preparation method of the transesterification inhibitor is to add the magnesium sulfate and copper hydroxide into a mixture of deionized water and 3 times ethanol whose mass is 100 times the mass of the two, stir and heat to 80 ° C, add The aluminum silicate, diethanol monoisopropanolamine, copper hydroxide, sodium citrate, and sodium lauryl sulfate were kept for 50 minutes, then cooled to 50°C, and mixed with fluoroantimonysulfonic acid, then heated at 45°C E...

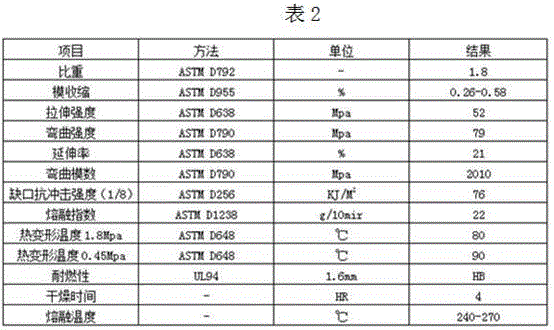

Embodiment 2

[0030] The present embodiment provides a kind of PBT / PC alloy material, and its raw material comprises by weight:

[0031] 6.5 copies of PBT;

[0032] PC 90 copies;

[0033] 0.2 part of transesterification inhibitor;

[0034] The raw materials of the transesterification inhibitor include by weight 2 parts of aluminum silicate, 0.03 part of diethanol monoisopropanolamine, 0.7 part of sodium lauryl sulfate, 3 parts of copper hydroxide, 0.2 part of sodium citrate, 0.07 Parts of fluoroantimonysulfonic acid.

[0035] The preparation method of the transesterification inhibitor is to add the magnesium sulfate and copper hydroxide into a mixture of deionized water and 3 times ethanol whose mass is 100 times the mass of the two, stir and heat to 80 ° C, add The aluminum silicate, diethanol monoisopropanolamine, copper hydroxide, sodium citrate, and sodium lauryl sulfate were kept for 50 minutes, then cooled to 50°C, and mixed with fluoroantimonysulfonic acid, then heated at 45°C Ev...

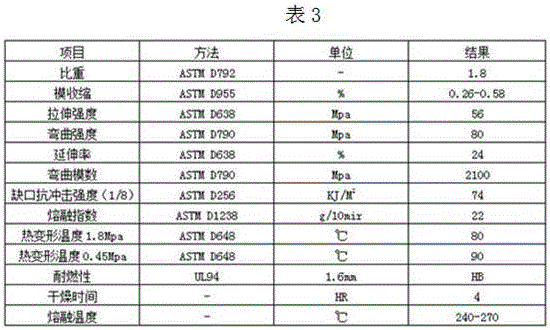

Embodiment 3

[0042] The present embodiment provides a kind of PBT / PC alloy material, and its raw material comprises by weight:

[0043] 42.6 copies of PBT;

[0044] PC 70 copies;

[0045] 0.7 part of transesterification inhibitor;

[0046] The raw materials of the transesterification inhibitor include by weight 2 parts of aluminum silicate, 0.03 part of diethanol monoisopropanolamine, 0.7 part of sodium lauryl sulfate, 3 parts of copper hydroxide, 0.2 part of sodium citrate, 0.07 Parts of fluoroantimonysulfonic acid.

[0047] The preparation method of the transesterification inhibitor is to add the magnesium sulfate and copper hydroxide into a mixture of deionized water and 3 times ethanol whose mass is 100 times the mass of the two, stir and heat to 80 ° C, add The aluminum silicate, diethanol monoisopropanolamine, copper hydroxide, sodium citrate, and sodium lauryl sulfate were kept for 50 minutes, then cooled to 50°C, and mixed with fluoroantimonysulfonic acid, then heated at 45°C Eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com