High-temperature-resistant organic temporary plugging agent and preparation method thereof

A technology of high temperature resistance and temporary plugging agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of difficulty in quality control and field application, complicated production process of temporary plugging agent, incomplete degradation, etc. Degradation and flowback, high success rate of temporary plugging, and short recovery period of oil wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

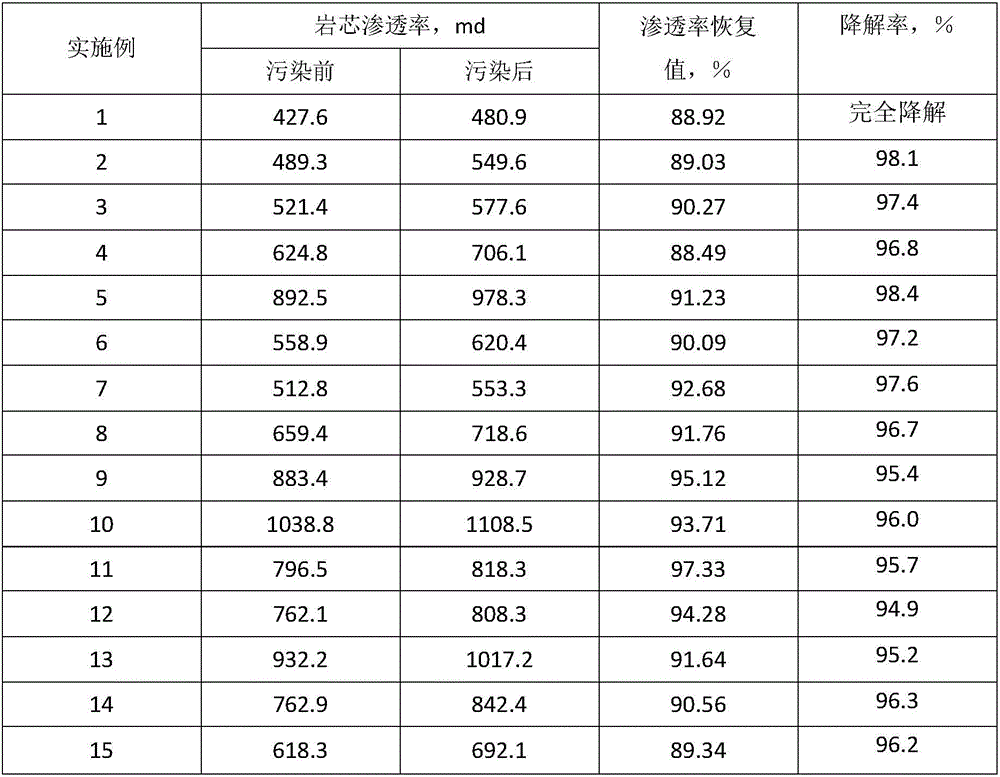

Examples

Embodiment 1

[0031] Example 1: Add 20g of acrylic acid, 40g of acrylamide, 20g of 2-acrylamide-2-methylpropanesulfonic acid, and 2g of N,N-methylenebisacrylamide to 9.3g of water in sequence at room temperature, mix the solution evenly, and use Sodium carbonate neutralizes the solution to pH = 6.5-7.0, put the solution in an open container, add 0.084g of sodium bisulfite and 0.084g of ammonium persulfate and stir evenly, and wait for initiation. A solid polymer is obtained through the reaction, and the polymer is pulverized to obtain an anti-high temperature organic temporary plugging agent.

Embodiment 2

[0032] Example 2: Add 20g of acrylic acid, 40g of acrylamide, 20g of 2-acrylamide-2-methylpropanesulfonic acid, and 2g of N,N-methylenebisacrylamide to 9.3g of water in sequence at room temperature, mix the solution evenly, and use Sodium carbonate neutralizes the solution to pH = 6.5-7.0, put the solution in an open container, add 0.084g sodium bisulfite and 0.084g potassium persulfate, stir well, and wait for initiation. A solid polymer is obtained through the reaction, and the polymer is pulverized to obtain an anti-high temperature organic temporary plugging agent.

Embodiment 3

[0033] Example 3: Add 20g of acrylic acid, 40g of acrylamide, 20g of 2-acrylamide-2-methylpropanesulfonic acid, and 2g of N,N-methylenebisacrylamide to 9.3g of water in sequence at room temperature, mix the solution evenly, and use Sodium carbonate neutralizes the solution to pH = 6.5-7.0, put the solution in an open container, add 0.084g of ammonium bisulfite and 0.084g of sodium persulfate and stir evenly, and wait for initiation. A solid polymer is obtained through the reaction, and the polymer is pulverized to obtain an anti-high temperature organic temporary plugging agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com