A new type of infrared radiation source

A radiation source and a new type of technology, applied in the field of infrared radiation sources, can solve the problems of narrow bandwidth of tungsten-halogen light source, complex black temperature control system, and large temperature influence, etc., and achieve the effect of compact structure, increased anti-seismic performance, and easy production and realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

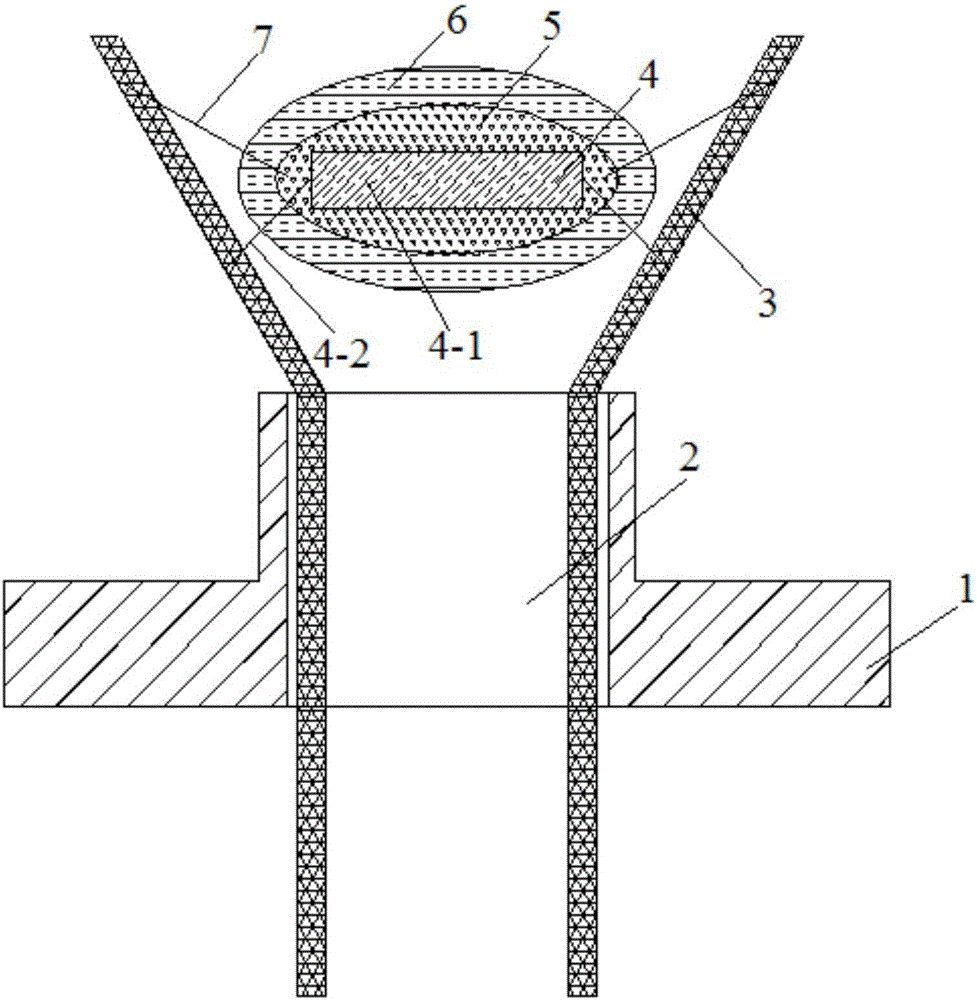

[0018] Specific implementation mode one: combine figure 1 , this embodiment is a new type of infrared radiation source, which includes a light source base 1, pin sintering tank 2, light source pin 3, heating wire 4, thermal insulation coating 5, protective coating 6 and fixing wire 7;

[0019] A pin sintering tank 2 is set on the light source base 1, and the light source pin 3 is fixed in the pin sintering tank 2;

[0020] The heating wire 4 is composed of a winding part 4-1 and a connecting part 4-2;

[0021] Cover the surface of the winding part 4-1 of the heating wire 4 with an insulating coating 5, and coat the insulating coating 5 with a protective coating 6;

[0022] The connection part 4-2 of the heating wire 4 is spot-welded to the light source pin 3;

[0023] One end of the fixing wire 7 is sintered into the thermal insulation coating 5 , and one end is spot welded to the light source pin 3 , and it is ensured that the fixing wire 7 is not in contact with the heatin...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 1 The difference between this embodiment and the first embodiment is that: the heating wire 4 is prepared by using a metal wire in a tightly wound manner. Others are the same as the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the metal wire is platinum wire, tungsten wire, platinum-iridium wire or nickel-chrome wire. Others are the same as those in Embodiment 1 or 2.

[0028] The diameter of the metal wire described in this embodiment is 0.02 mm to 0.05 mm.

[0029] In this embodiment, platinum wires, tungsten wires, platinum-iridium wires or nickel-chromium wires with good oxidation resistance are used as heating wires to avoid the oxidation phenomenon that occurs when power is applied for a long time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com