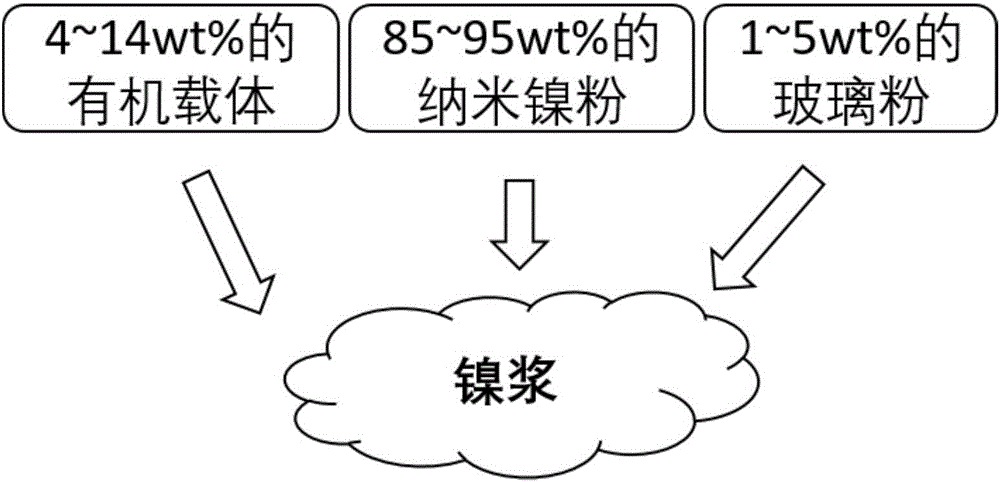

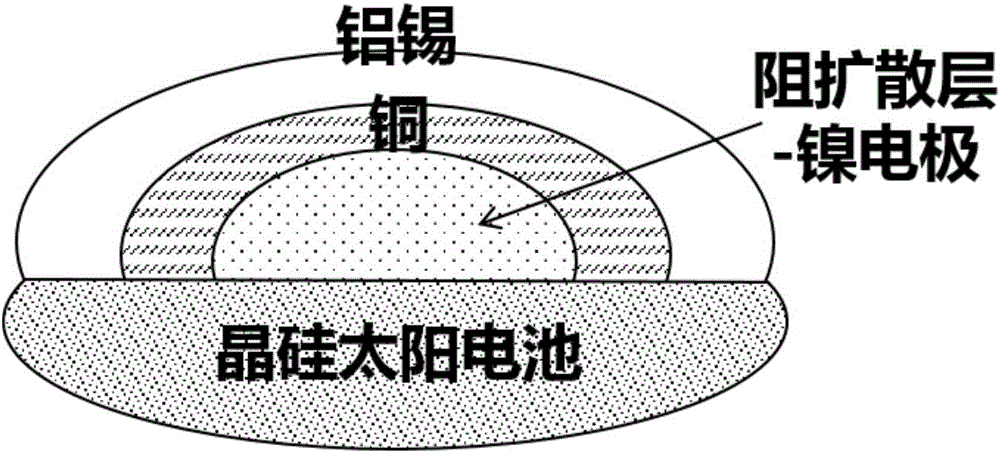

Nickel slurry for positive blocking spreading layer electrode of crystal silicon solar battery and preparation method thereof

A technology of crystalline silicon solar cells and diffusion resistance layers, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. problems such as large thermal damage, to achieve the effects of low diffusivity, low cost, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Put 14wt% of the organic vehicle in a container, place the container in a constant temperature water tank with a temperature of 60° C., and continuously stir the organic vehicle in the container at a rate of 180 rpm, and heat and stir for 10 hours. Add 85wt% nano-nickel powder at a rate of 5g / min to prepare mixture a. Wherein, the particle diameter of nanometer nickel powder is 500~800nm, and purity is greater than 99%; Polyamide wax, 6wt% lecithin, 5wt% tributyl phosphate, 4wt% polyethylene glycol composition, diethylene glycol butyl ether, tributyl citrate, ethyl cellulose, polyamide wax , lecithin, tributyl phosphate and polyethylene glycol are mixed evenly in proportion, placed in a constant temperature container at 80°C, and stirred for 5 hours.

[0029] (2) The temperature of the constant temperature water tank is increased to 80°C, and the mixture a prepared in step (1) in the container is constantly stirred at a rate of 200 rpm. After heating and stirring f...

Embodiment 2

[0033] (1) Put 10 wt% of the organic vehicle in a container, place the container in a constant temperature water tank with a temperature of 70° C., and continuously stir the organic vehicle in the container at a rate of 140 rpm, and heat and stir for 5 hours. Add 85wt% nano-nickel powder at a rate of 20g / min to prepare mixture a. Wherein, the particle diameter of nanometer nickel powder is 500~800nm, and purity is greater than 99%; Polyamide wax, 6wt% lecithin, 5wt% tributyl phosphate, 4wt% polyethylene glycol composition, diethylene glycol butyl ether, tributyl citrate, ethyl cellulose, polyamide wax , lecithin, tributyl phosphate and polyethylene glycol are mixed evenly in proportion, placed in a constant temperature container at 80°C, and stirred for 5 hours.

[0034] (2) The temperature of the constant temperature water tank is increased to 90°C, and the mixture a prepared in the step (1) in the container is constantly stirred at a rate of 160 rpm. After heating and stirr...

Embodiment 3

[0038] (1) Put 10 wt% of the organic vehicle in a container, place the container in a constant temperature water tank with a temperature of 80° C., and continuously stir the organic vehicle in the container at a rate of 90 rpm. After heating and stirring for 1 hour, Add 89wt% nano-nickel powder at a rate of 30g / min to prepare mixture a. Wherein, the particle diameter of nanometer nickel powder is 500~800nm, and purity is greater than 99%; Polyamide wax, 6wt% lecithin, 5wt% tributyl phosphate, 4wt% polyethylene glycol composition, diethylene glycol butyl ether, tributyl citrate, ethyl cellulose, polyamide wax , lecithin, tributyl phosphate and polyethylene glycol are mixed evenly in proportion, placed in a constant temperature container at 80°C, and stirred for 5 hours.

[0039] (2) The temperature of the constant temperature water tank is raised to 100° C., and the mixture a prepared in step (1) in the container is constantly stirred at a rate of 120 rpm. After heating and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com