High conductivity low temperature silver paste

A high-conductivity, low-temperature technology, used in cable/conductor manufacturing, circuits, conductive materials dispersed in non-conductive inorganic materials, etc. It can avoid problems such as poor hardness of the film, and achieve the effect of avoiding the decline of the overall performance of the film, improving the mechanical properties and good wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

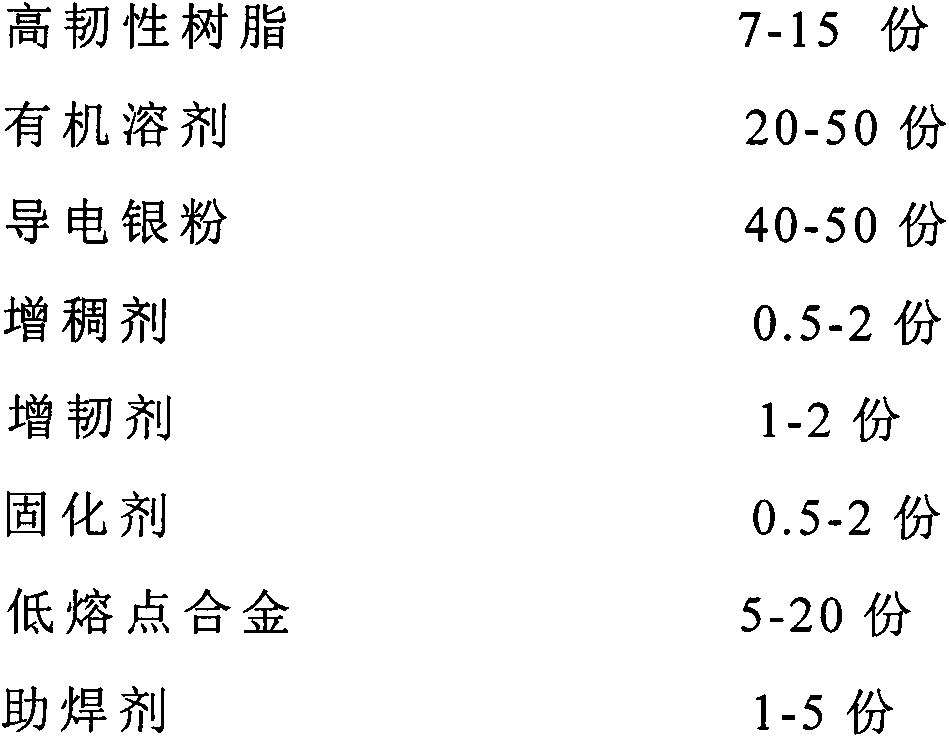

[0045] Preparation of High Conductivity Low Temperature Silver Paste

[0046] According to the formula in Table 1, mix and disperse the high-toughness resin, thickener, toughening agent, curing agent, and organic solvent in sequence; then add low-melting point alloy, flux, and conductive silver powder in sequence, and stir at 1200 rpm for 15 minutes to obtain Slurry: use a three-roll grinder to grind the obtained slurry to a fineness of 5-10 μm to obtain conductive silver paste.

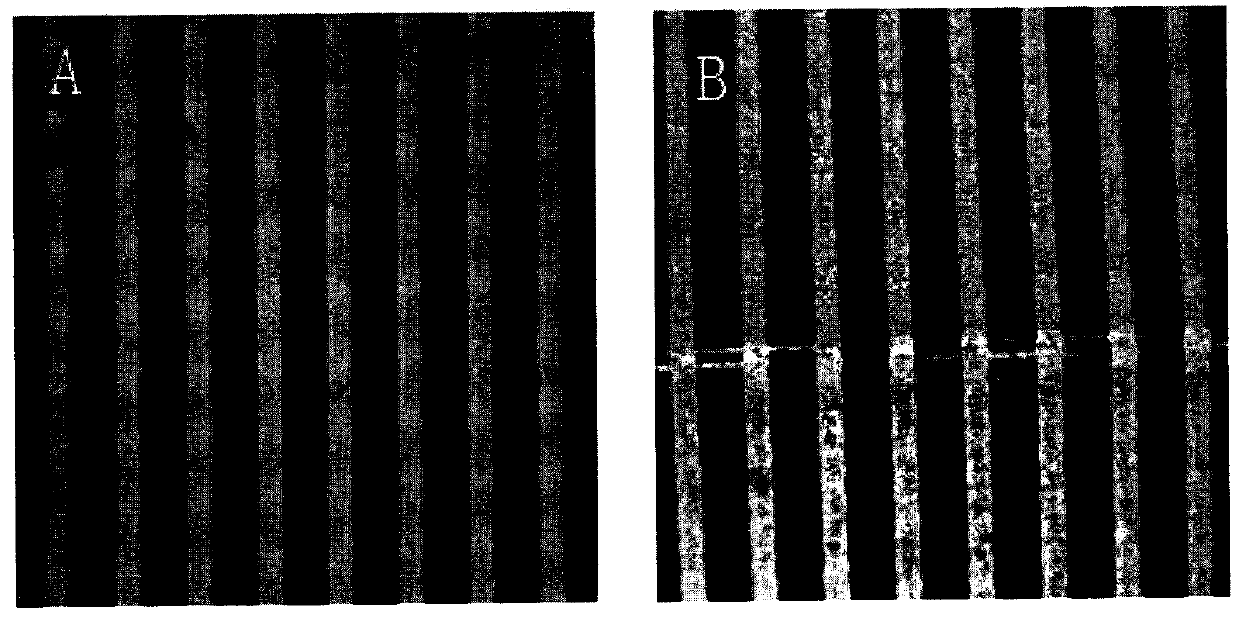

[0047] Print conductive silver paste evenly on PET by screen printing, bake the PET film in a blast oven at 150°C for 50 minutes, take it out and cool it, measure the line thickness (film thickness is 4-6 microns), line resistance, Hardness, adhesion, bending and other performance results. According to the film thickness, line resistance, line width, and line length, use the squar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com