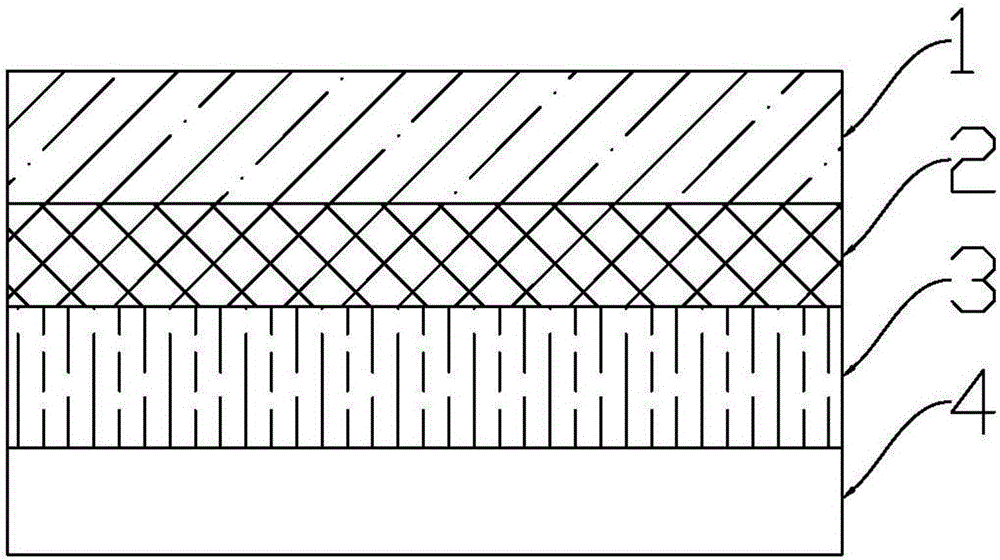

Composite transparent conductive film and preparation method thereof

A technology of transparent conductive film and composite structure, applied in metal/alloy conductors, carbon-silicon compound conductors, cable/conductor manufacturing, etc., can solve the problems of reduced composite conductivity, increased surface resistance, poor GO conductivity, etc. Water resistance stability, improvement of heat resistance stability, effect of preventing silver wire oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

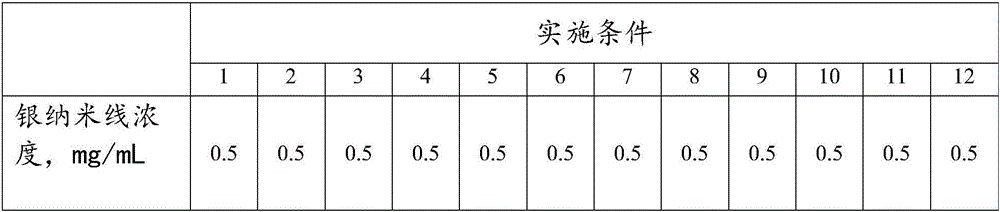

[0069] (1) Preparation of silver nanowire coating solution

[0070] The silver nanowire aqueous dispersion with a diameter of 25-30nm and a length of 20-30μm is used as the main raw material, and based on the solid content of the silver wire, 1 / 5 of the emulsifier (such as Triton X-100, cellulose, etc.) Water-soluble polymer additives) and 1 / 5 of water-based resin (such as Dutch Starr PU-704, PU-653 and other water-based polyurethane emulsions), and diluted with deionized water to a silver line concentration of 0.5mg / mL , preparing a coating liquid that can be used for spraying;

[0071] (2) Preparation of LLC coating solution

[0072] The prepared LLC is proportioned and diluted with ethanol to a certain solid content to prepare a coatable LLC solution;

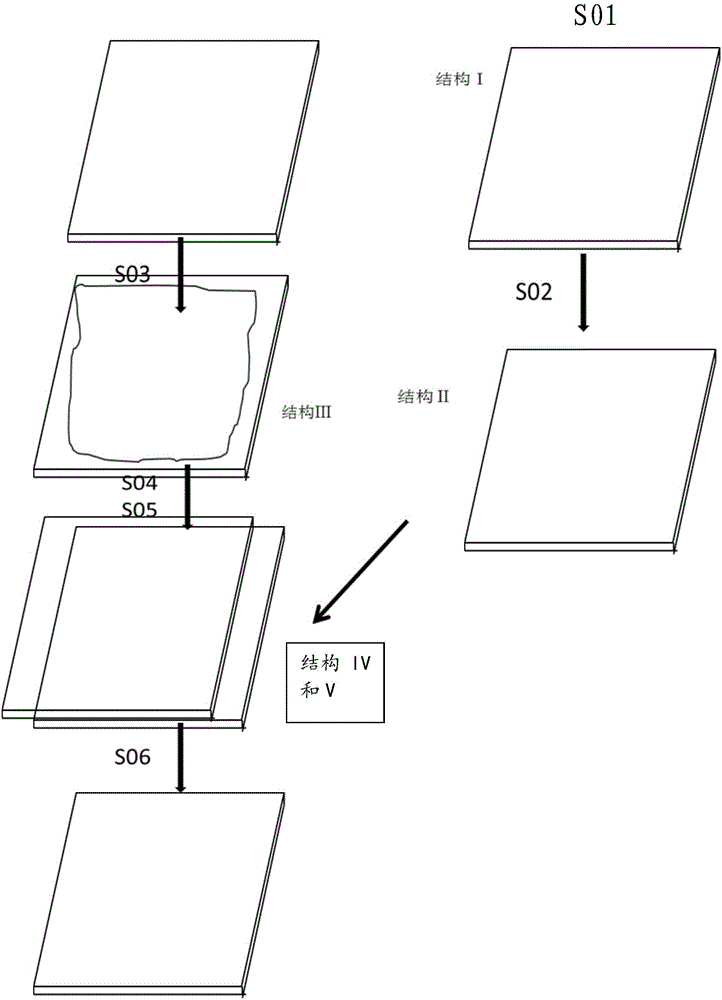

[0073] (3) Coating silver nanowire layer

[0074] Apply the silver nanowire coating solution prepared in step (1) evenly on the surface of the metal substrate (i.e. structure I) with the graphene layer grown by spraying; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com