SPPs (Surface Plasma Polaritons) thin film heterojunction and perovskite laminated solar cell and preparation method of solar cell

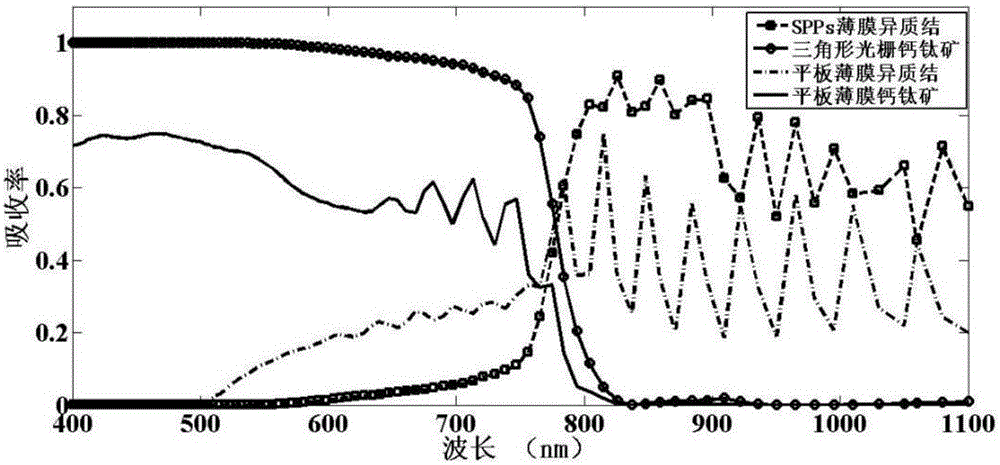

A technology of perovskite cells and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that the spectrum is not fully utilized and is limited to 300-800nm, so as to improve the photoelectric conversion efficiency and broaden the Effect of Spectral Absorption Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

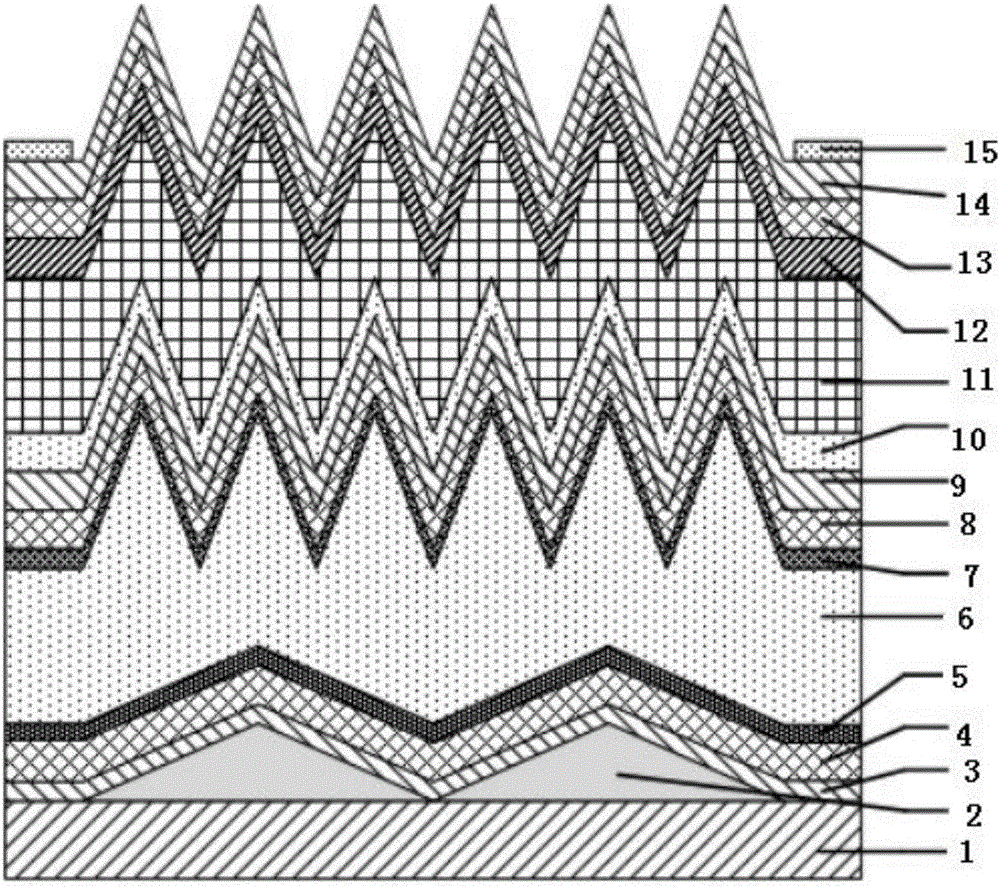

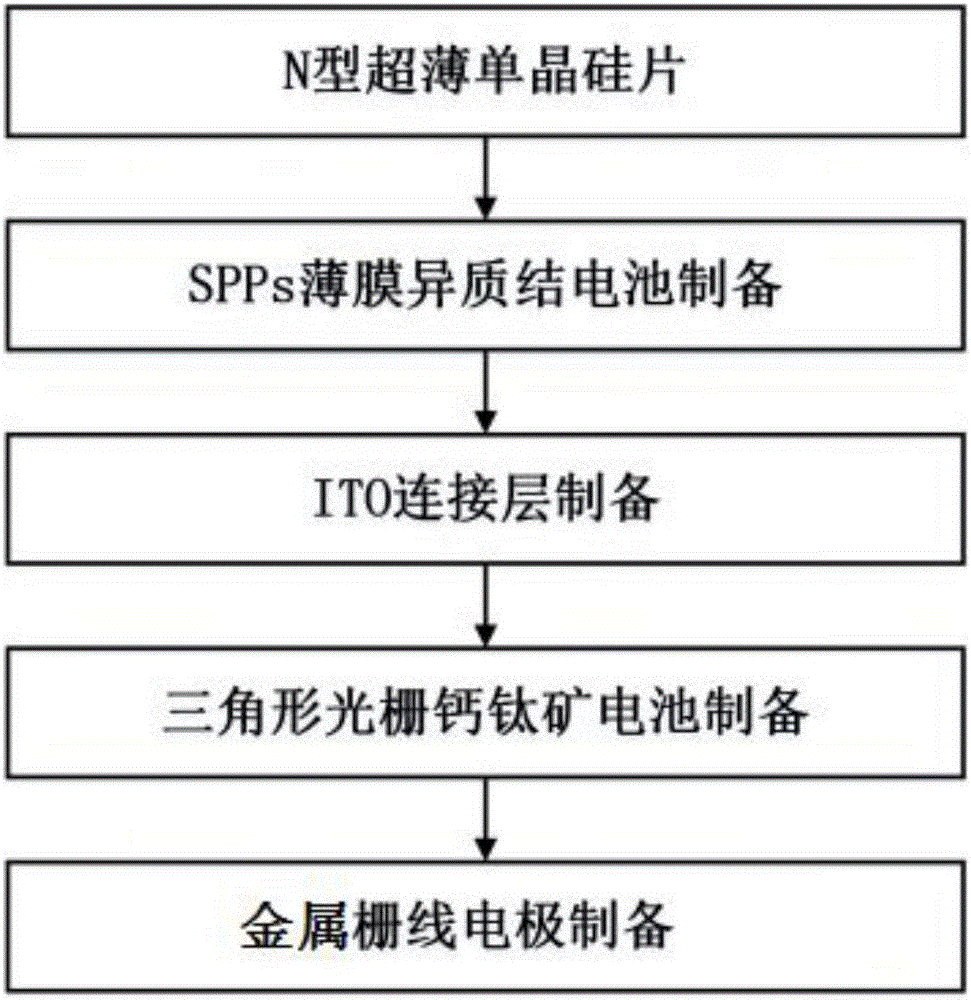

[0034] combined with figure 1 As shown in the schematic structural diagram, this embodiment provides a solar cell with a SPPs thin film heterojunction and a perovskite laminate, and the solar cell is as follows from top to bottom: an aluminum electrode 1; an SPPs thin film heterojunction solar cell; ITO connection layer 9; triangular grating perovskite cell; metal grid line electrode 15. The SPPs thin film heterojunction solar cells are as follows from bottom to top: triangular silver nano grating 2, conformal Si 3 N 4 Isolation layer 3, conformal N + Type amorphous silicon layer 4, conformal intrinsic amorphous silicon layer 5, N-type monocrystalline silicon layer 6, intrinsic amorphous silicon layer 7 and P + type amorphous silicon layer 8 . The triangular grating perovskite cell is as follows from bottom to top: ZnO electron transport layer 10, CH with triangular grating structure 3 NH 3 PB 3 Perovskite layer 11, conformal structure Spiro-OMeTAD hole transport layer ...

Embodiment 2

[0045] combined with figure 1 As shown in the schematic structural diagram, this embodiment provides a solar cell with a SPPs thin film heterojunction and a perovskite laminate, and the solar cell is as follows from top to bottom: an aluminum electrode 1; an SPPs thin film heterojunction solar cell; ITO connection layer 9; triangular grating perovskite cell; metal grid line electrode 15. The SPPs thin film heterojunction solar cells are as follows from bottom to top: triangular silver nano grating 2, conformal Si 3 N 4 Isolation layer 3, conformal N + Type amorphous silicon layer 4, conformal intrinsic amorphous silicon layer 5, N-type monocrystalline silicon layer 6, intrinsic amorphous silicon layer 7 and P + type amorphous silicon layer 8 . The triangular grating perovskite cell is as follows from bottom to top: ZnO electron transport layer 10, CH with triangular grating structure 3 NH 3 PB 3 Perovskite layer 11, conformal structure Spiro-OMeTAD hole transport layer ...

Embodiment 3

[0056] combined with figure 1 As shown in the schematic structural diagram, this embodiment provides a solar cell with a SPPs thin film heterojunction and a perovskite laminate, and the solar cell is as follows from top to bottom: an aluminum electrode 1; an SPPs thin film heterojunction solar cell; ITO connection layer 9; triangular grating perovskite cell; metal grid line electrode 15. The SPPs thin film heterojunction solar cells are as follows from bottom to top: triangular silver nano grating 2, conformal Si 3 N 4 Isolation layer 3, conformal N + Type amorphous silicon layer 4, conformal intrinsic amorphous silicon layer 5, N-type monocrystalline silicon layer 6, intrinsic amorphous silicon layer 7 and P+ type amorphous silicon layer 8. The triangular grating perovskite cell is as follows from bottom to top: ZnO electron transport layer 10, CH with triangular grating structure 3 NH 3 PB 3 Perovskite layer 11, conformal structure Spiro-OMeTAD hole transport layer 12,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com