Preparation method of antibacterial acellular dermal matrix dressing material

A technology of acellular dermis and dermal matrix, which is applied in the field of preparation of antibacterial acellular dermal matrix dressings, can solve the problems of low antibacterial performance, limit the wide application of acellular dermal matrix dressings, and poor biocompatibility, and achieve low antigenicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

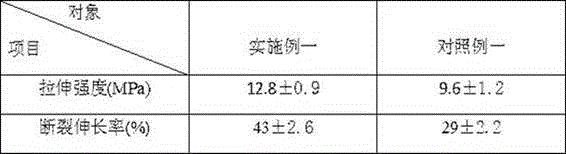

Embodiment 1

[0024] Peel off the skin of healthy newborn pigs and remove the hair; use a skin remover to make a sliced skin with a thickness of 0.8mm; use laser drilling technology to make holes in the sliced skin with a hole diameter of 0.3mm and a hole distance of 2mm ; Then use cobalt 60 to irradiate and sterilize the tomographic skin slices, the dose is 30kGy, and the irradiation time is 12h; the sterilized dermis matrix is placed in a -40°C ultra-low temperature refrigerator for 3h, and then placed in - Pre-freeze in a 75°C ultra-low temperature refrigerator for 3 hours, take it out, put it in a 37°C water bath to thaw for 1 hour, and freeze and thaw repeatedly 3 times; add the freeze-thawed dermal matrix to the buffer and clean it with ultrasonic waves, and the frequency of ultrasonic shock treatment 5 times, each time for 30 minutes; then use a mass concentration of 1.0% NaOH solution and a mass concentration of 0.4% ammonium lauryl sulfate anionic surfactant mixture to degreas...

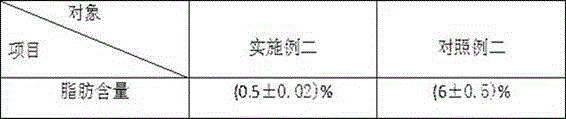

Embodiment 2

[0026] Peel off the skin of healthy newborn pigs and remove the hair; use a skin remover to make a sliced skin with a thickness of 0.5 mm; use laser drilling technology to make holes in the sliced skin with a hole diameter of 0.1 mm and a hole distance of 1.5 mm; then sterilize the sliced skin slices by irradiation with cobalt 60, the dose is 25kGy, and the irradiation time is 10h; the sterilized dermal matrix is pre-frozen in a -30℃ ultra-low temperature refrigerator for 2h, and then placed in Take it out after being pre-frozen in the ultra-low temperature refrigerator at -70°C for 2 hours, thaw it in a 37°C water bath for 1 hour, and freeze and thaw twice; add the freeze-thawed dermal matrix into the buffer and clean it with ultrasonic waves The frequency is 3 times, each time for 30 minutes; then use a mass concentration of 1.0% NaOH solution and a mass concentration of 0.1% fatty alcohol sodium isethionate anionic surfactant mixture to degrease the cleaned dermal ma...

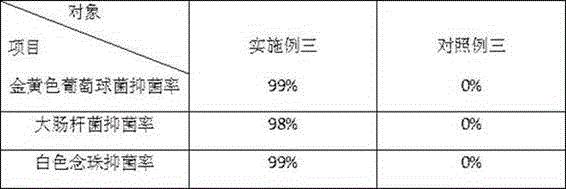

Embodiment 3

[0028] Peel off the skin of healthy newborn pigs and remove the hair; use a skin remover to make a sliced skin with a thickness of 1.5 mm; use laser drilling technology to make holes in the sliced skin with a hole diameter of 0.5 mm and a hole distance of 2.5 mm; then sterilize the tomographic skin slices with cobalt 60 irradiation, the dose is 50kGy, and the irradiation time is 15h; the sterilized dermal matrix is pre-frozen in a -50℃ ultra-low temperature refrigerator for 3h, and then placed in Take it out after being pre-frozen in the ultra-low temperature refrigerator at -80°C for 3 hours, thaw it in a water bath at 37°C for 1 hour, and freeze and thaw repeatedly 4 times; The frequency is 7 times, each time for 30 minutes; then degrease the cleaned dermal matrix with a mass concentration of 2.0% NaOH solution and a mass concentration of 0.6% dodecyl phosphate anionic surfactant mixture; Decellularize the decellularized dermal matrix with 3.0% TritonX-100; then soak t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com