Method for preparing composite nanofiltration membrane by tannic acid/Fe<3+> cocoating

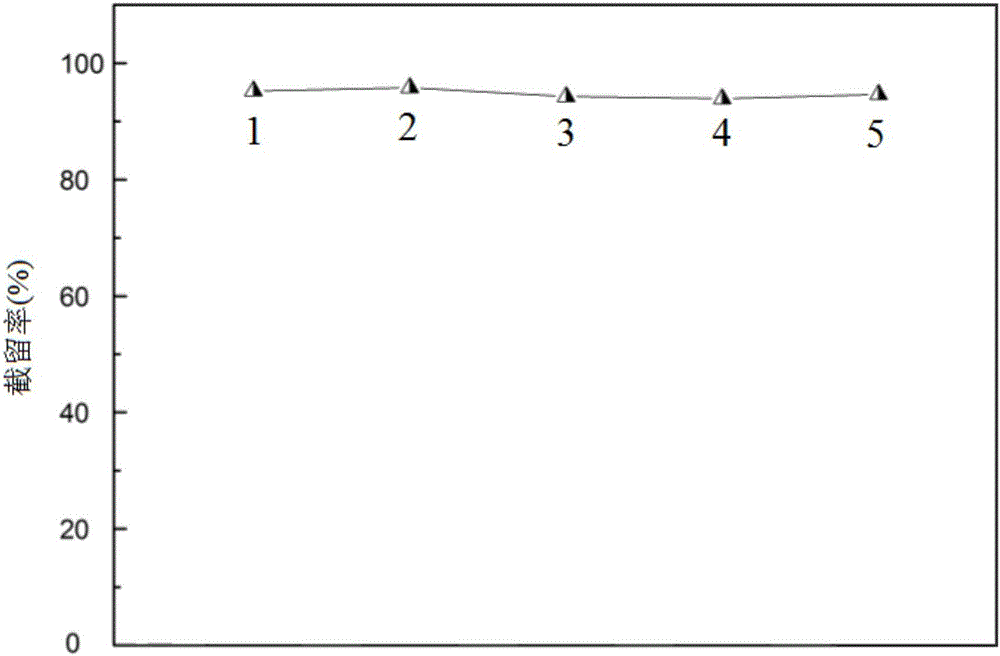

A technology of composite nanofiltration membrane and tannic acid, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of poor separation performance, unstable structure, and easy contamination by microorganisms of nanofiltration membranes, so as to avoid complex Excellent operating environment, simple operation process, and easy to expand the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

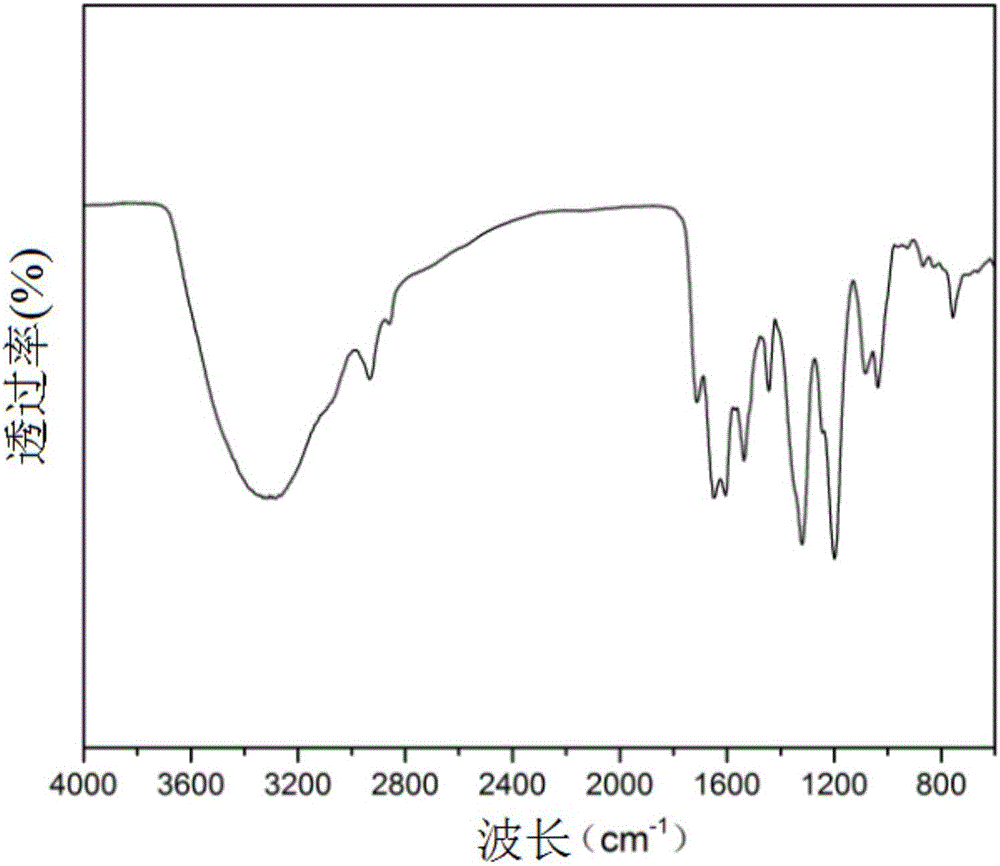

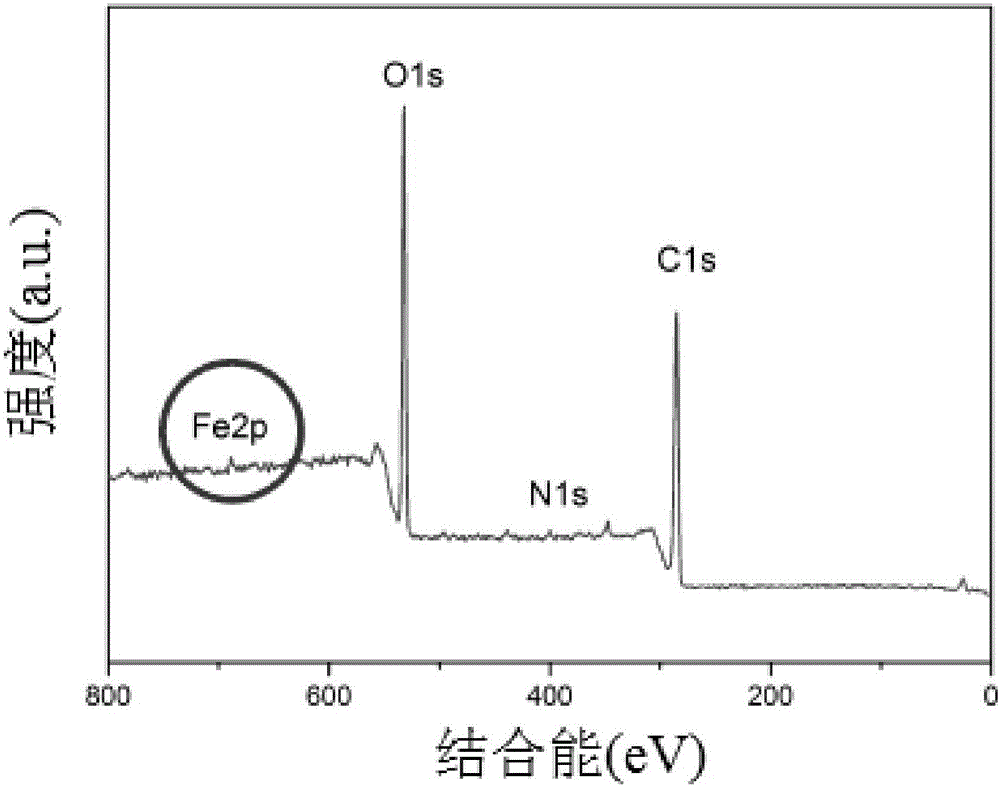

[0026] Specific embodiment one: this embodiment is a kind of tannic acid and Fe 3+ The method for preparing the composite nanofiltration membrane by co-coating is specifically completed in the following steps:

[0027] 1. Prepare polymer solution: dissolve the dried polymer in a solvent to obtain a polymer solution with a mass fraction of 14% to 18%;

[0028] 2. Pour the polymer solution with a mass fraction of 14% to 18% on a clean glass plate to cast and scrape the film. After scraping the film, evaporate it in the air for 10s to 30s and then immerse it in the non-solvent system. Take it out after 20min to 40min. , and then immersed in distilled water to obtain the ultrafiltration membrane matrix after taking it out;

[0029] 3. Dissolve tannic acid and iron salt into water to obtain tannic acid and Fe 3+ aqueous phase solution; the ultrafiltration membrane substrate obtained in step 2 is immersed in tannic acid and Fe 3+ Stand in the water phase solution of 2h~12h, get t...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment differs from Embodiment 1 in that the polymer described in step 1 is polyimide, polyacrylonitrile, polysulfone or polyethersulfone. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0039]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the solvent described in step 1 is N-methylpyrrolidone. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com