A kind of preparation method of oil-soluble initiator microcapsule

An oil-soluble initiator and microcapsule technology, which is applied in the fields of oil field development, chemical engineering, coatings, and anaerobic adhesives. It can solve the problem of difficulty in meeting the requirements for the preparation of anaerobic adhesives, the difficulty in effectively controlling the release time and method of microcapsules, and stable storage. Poor performance and other problems, to achieve the effect of controllable release time, low cost and high package rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh a certain mass ratio of deionized water, Span 80 and TX-100 into the reactor, deionized water, Span 80 and TX-100 respectively account for 93.38%, 0.6%, and 0.4% of the total weight of the feed ;

[0022] (2) add a certain amount of benzoyl peroxide, aniline and terpene resin in the reactor, benzoyl peroxide, aniline and terpene resin account for 4%, 1.5%, 0.1% of the total weight of feeding intake respectively, in Emulsification reaction at room temperature for 12-15 minutes;

[0023] (3) Add ammonium persulfate accounting for 0.02% of the total weight of the feed into the reactor, continue to react for 7-8 hours, and wash with ethanol three times to obtain oil-soluble initiator microcapsules.

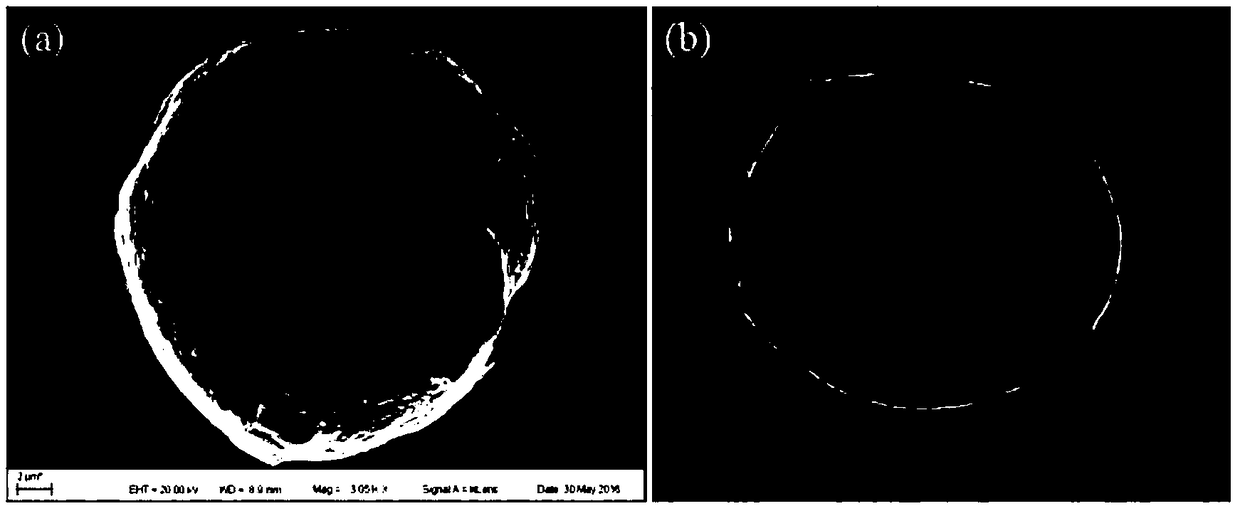

[0024] figure 1 A is the scanning electron micrograph of the embodiment of the present invention 1 oil-soluble initiator microcapsule; figure 1 b is the transmission electron micrograph of the oil-soluble initiator microcapsule in Example 1 of the present invention...

Embodiment 2

[0026] (1) Weigh a certain mass ratio of deionized water, Span 80 and TX-100 into the reactor, and deionized water, Span 80 and TX-100 account for 87.65%, 1% and 0.8% of the total weight of the feed respectively ;

[0027] (2) Add a certain amount of cumene hydroperoxide, aniline and terpene resin to the reactor, and cumene hydroperoxide, aniline and terpene resin account for 7%, 3%, 0.5% of the total weight of the feed intake respectively , emulsification reaction at room temperature for 12 to 15 minutes;

[0028] (3) Add ammonium persulfate accounting for 0.05% of the total weight of the feed into the reactor, continue to react for 7-8 hours, and wash with ethanol three times to obtain oil-soluble initiator microcapsules.

Embodiment 3

[0030] (1) Weigh a certain mass ratio of deionized water, Span 80 and TX-100 into the reactor, deionized water, Span 80 and TX-100 respectively account for 91.58%, 0.7%, and 0.5% of the total weight of the feed ;

[0031] (2) Add a certain amount of azobisisobutyronitrile, aniline and terpene resins to the reactor, and azobisisobutyronitrile, aniline and terpene resins account for 5%, 2%, and 0.2% of the total weight of the feed respectively , emulsification reaction at room temperature for 12 to 15 minutes;

[0032] (3) Add ammonium persulfate accounting for 0.02% of the total weight of the feed into the reactor, continue to react for 7-8 hours, and wash with ethanol three times to obtain oil-soluble initiator microcapsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com