Preparation method of photothermal response type composite gel hollow microsphere

A composite gel and hollow microsphere technology, applied in the chemical industry, achieves good dispersion, mild reaction conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

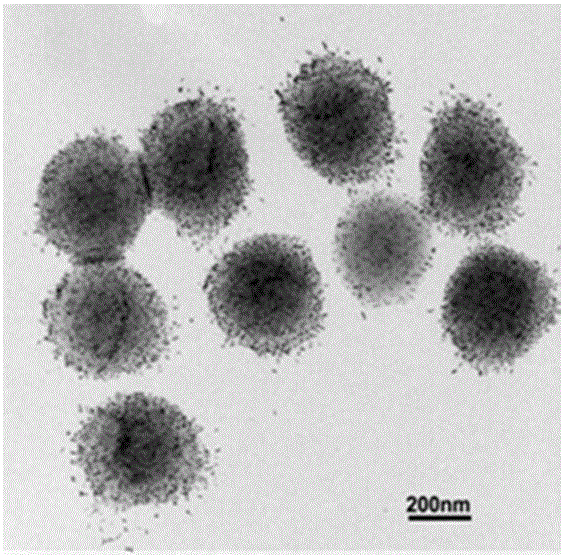

[0022] A photothermal responsive composite gel hollow microsphere, characterized in that the photothermal responsive composite gel hollow microsphere is made of SiO 2 Solid spheres as templates, and P(NIPAM-AM) / SiO with core-shell structure prepared by surface graft polymerization 2 Composite gel microspheres, followed by HF etching of SiO 2 template to form P(NIPAM-AM) gel hollow microspheres, and use the gel hollow microspheres as microreactors to prepare photothermally responsive composite gel hollow microspheres loaded with AuNRs in situ. The type composite gel hollow microspheres are used in the DOX phosphate buffer solution system to realize the effective controlled release of the loaded substance DOX under the conditions of near-infrared light and temperature.

[0023] The preparation method of photothermal responsive composite gel hollow microspheres comprises the following steps:

[0024] (1) Add 8.5 mL of NH with a mass fraction of 25-28% 3 ·H 2 O, 15 mL C 2 h ...

Embodiment 2

[0034] A photothermal responsive composite gel hollow microsphere, characterized in that the photothermal responsive composite gel hollow microsphere is made of SiO 2 Solid spheres as templates, and P(NIPAM-AM) / SiO with core-shell structure prepared by surface graft polymerization 2 Composite gel microspheres, followed by HF etching of SiO 2 template to form P(NIPAM-AM) gel hollow microspheres, and use the gel hollow microspheres as microreactors to prepare photothermally responsive composite gel hollow microspheres loaded with AuNRs in situ. The type composite gel hollow microspheres are used in the DOX phosphate buffer solution system to realize the effective controlled release of the loaded substance DOX under the conditions of near-infrared light and temperature.

[0035] The preparation method of photothermal responsive composite gel hollow microspheres comprises the following steps:

[0036] (1) Add 9.5 mL of 25%-28% NH 3 ·H 2 O, 17 mL C 2 h 5 OH and 25mL H 2 O wa...

Embodiment 3

[0046] A photothermal responsive composite gel hollow microsphere, characterized in that the photothermal responsive composite gel hollow microsphere is made of SiO 2 Solid spheres as templates, and P(NIPAM-AM) / SiO with core-shell structure prepared by surface graft polymerization 2 Composite gel microspheres, followed by HF etching of SiO 2 template to form P(NIPAM-AM) gel hollow microspheres, and use the gel hollow microspheres as microreactors to prepare photothermally responsive composite gel hollow microspheres loaded with AuNRs in situ. The type composite gel hollow microspheres are used in the DOX phosphate buffer solution system to realize the effective controlled release of the loaded substance DOX under the conditions of near-infrared light and temperature.

[0047] The preparation method of photothermal responsive composite gel hollow microspheres comprises the following steps:

[0048] (1) Add 8.8 mL of NH with a mass fraction of 25%-28% 3 ·H 2 O, 16 mL C 2 h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com