Ice breaking and removing method based on plasma impact jet flow

A plasma and impinging jet technology, applied in deicing devices, aircraft parts, transportation and packaging, etc., can solve the problems of changing the aerodynamic shape of the aircraft, insufficient deicing speed, and structural fatigue, so as to avoid structural fatigue problems and reduce air pollution. Breakdown voltage, the effect of easy electrical parameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

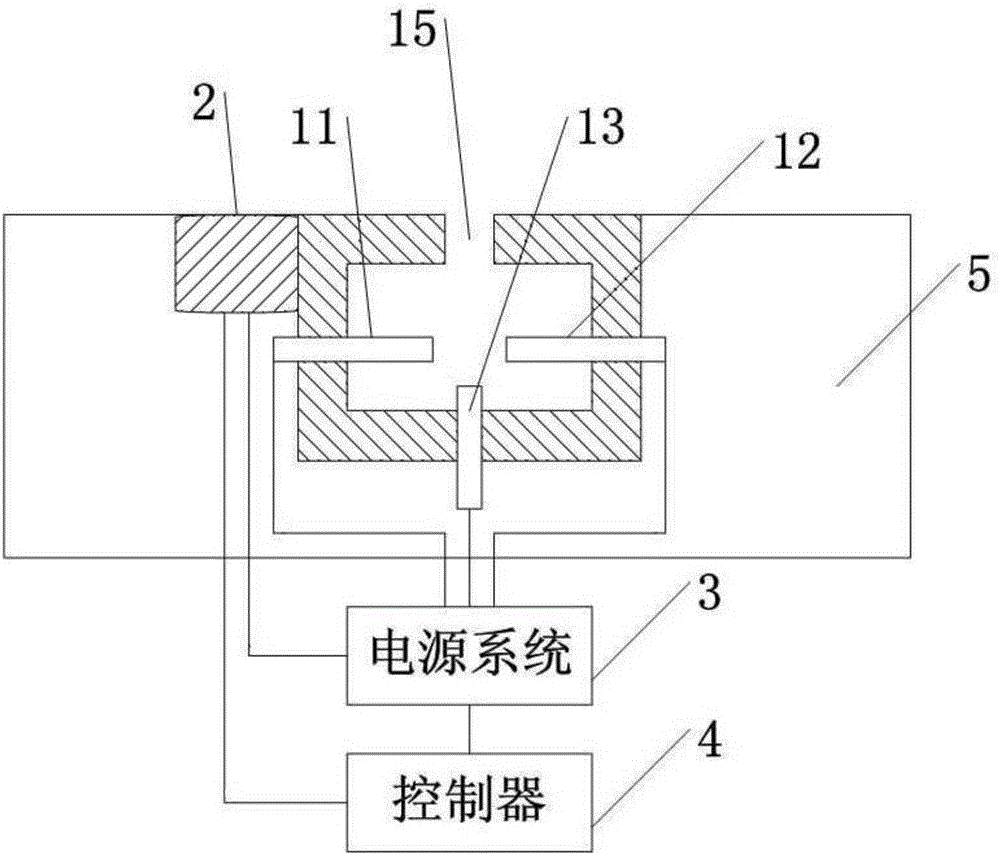

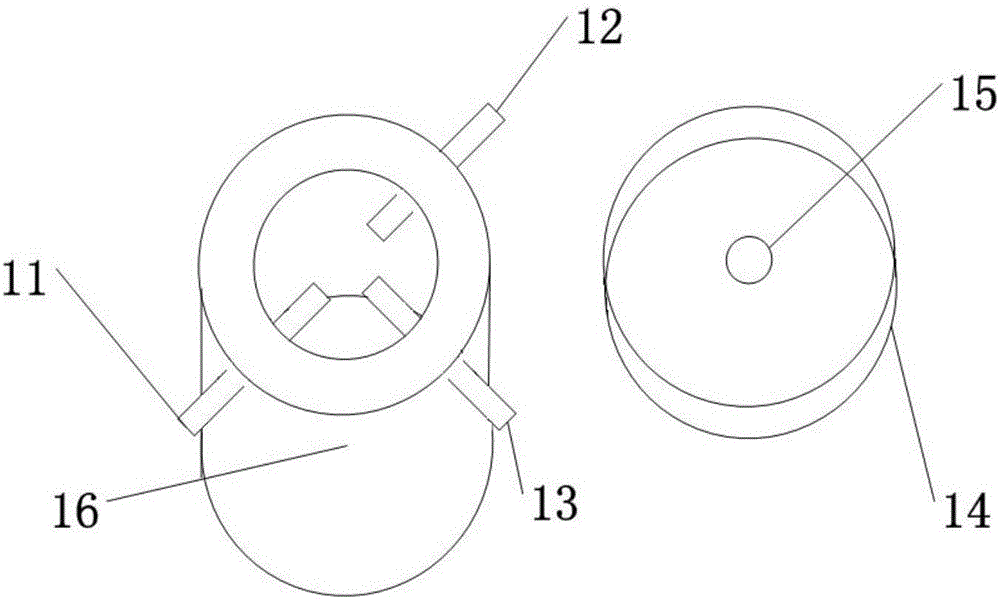

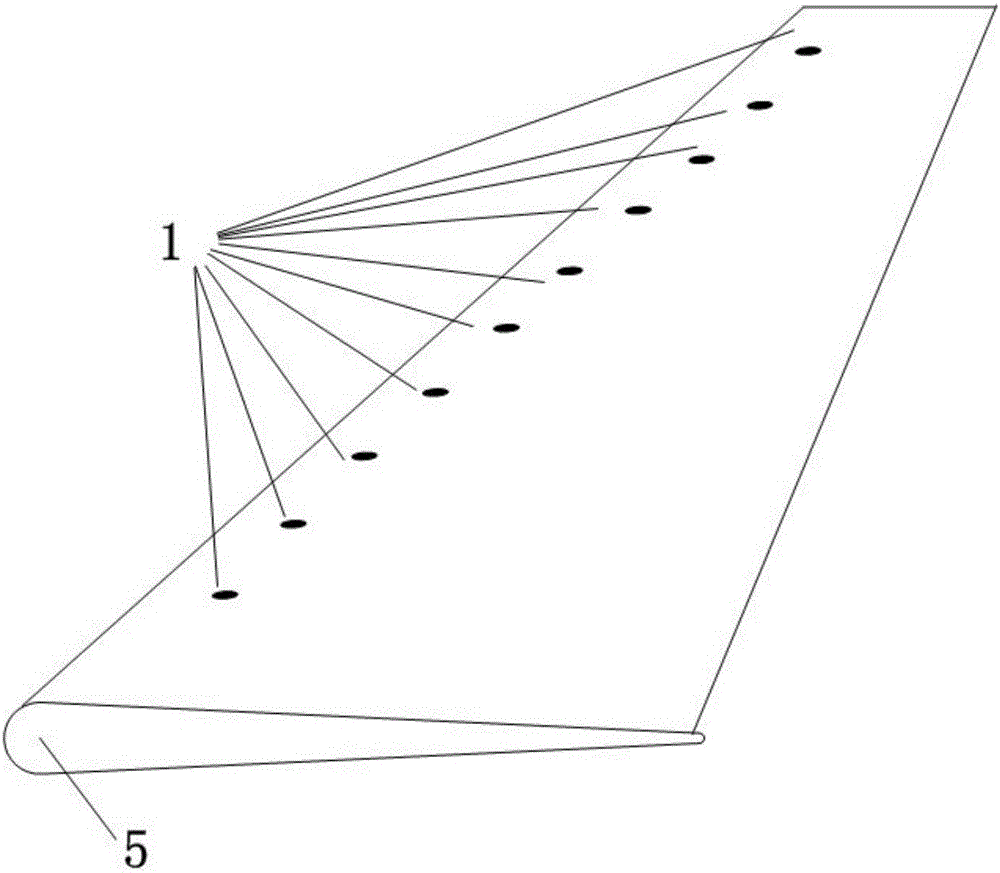

[0034] In this embodiment, the wing on the aircraft is selected as the application object for ice breaking, such as figure 1 As shown, the plasma exciter 1 and the icing detector 2 are both installed on the wing 5. The wing 5 is provided with mounting holes for installing the plasma exciter 1 and the icing detector 2. The plasma exciter 1 and the icing detector 2 are installed in the corresponding mounting holes on the wing 5. After the plasma exciter 1 and the icing detector 2 are installed, the outer surface of the plasma exciter 1 and the icing detector 2 are the same as the aircraft on the wing. The surface of the wing is flush, that is, neither convex nor concave, so that the aerodynamic shape of the wing installed with the plasma impinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com