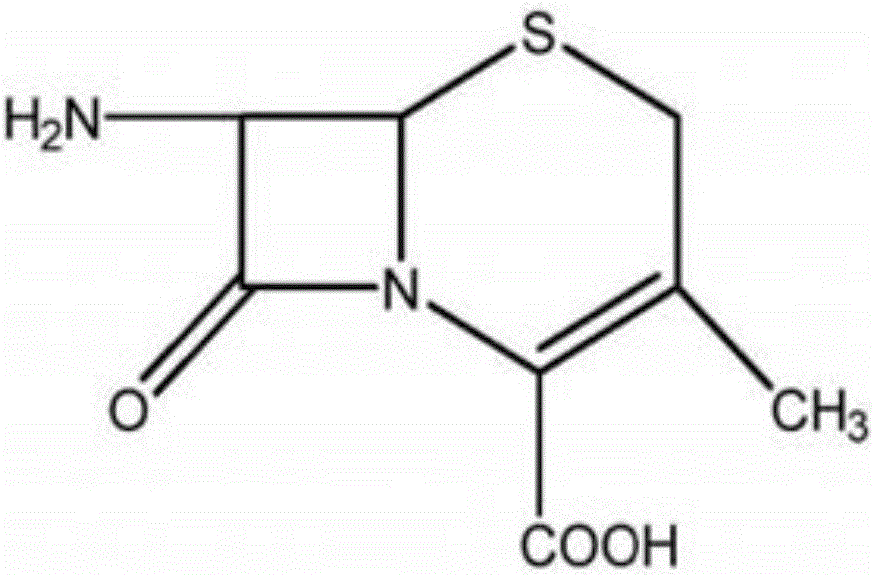

Method for recovering 7-ADCA mother liquor

A technology of 7-ADCA and mother liquor recovery, applied in organic chemistry and other fields, can solve problems such as waste, and achieve the effects of less pollution, increased weight yield, and low operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

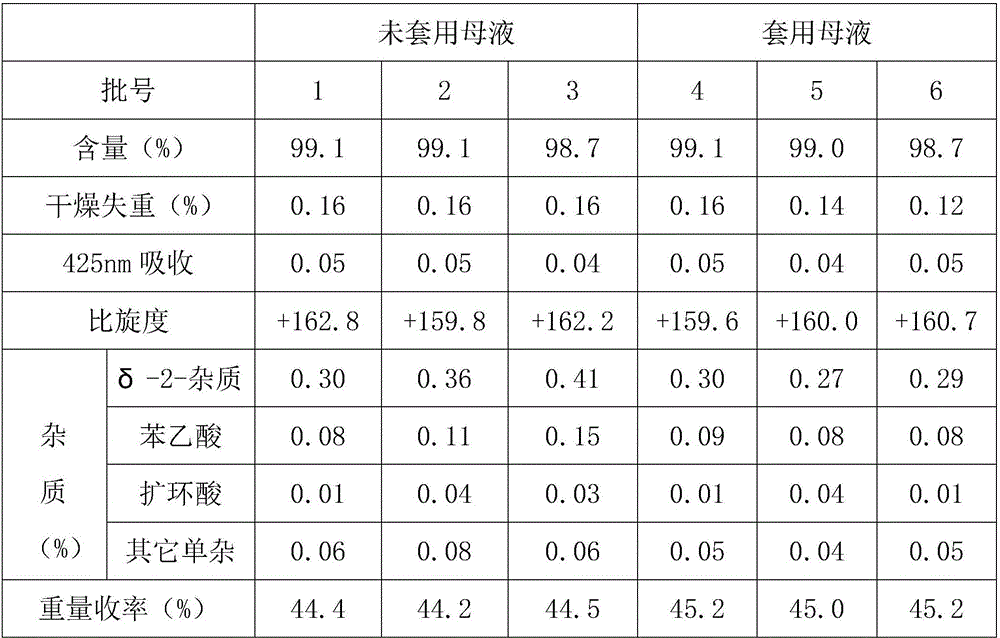

Embodiment 1

[0038] Take 60L of 7-ADCA mother liquor with a concentration of 490ug / ml, and adjust the pH of the mother liquor to 6.0 with 20% aqueous sodium hydroxide solution. The temperature was controlled at 20°C, and then adsorbed by macroporous resin, the adsorption flow rate was set at 1.0BV / h, and the resin column had a capacity of 12L. Then analyze with 2% sodium bicarbonate aqueous solution at a rate of 1.0 BV / h, and control the temperature at 20°C. The analyzed feed liquid is clarified by ultrafiltration, the pressure of ultrafiltration is 4bar, and the flux is 46LMH. The mixed dialysate after ultrafiltration is then concentrated by nanofiltration. The pressure of nanofiltration is 15bar, and the flux is 20LMH. The concentrated solution was 4L, the concentration was 6.20g / L, and the yield was 84.3%. The concentrated solution was directly reused until the 7-ADCA diexpannic acid was dissolved to replace 4 L of dissolved water, and the final 7-ADCA yield increased by 0.90%.

Embodiment 2

[0040] Take 60L of 7-ADCA mother liquor with a concentration of 420ug / ml, and adjust the pH of the mother liquor to 6.2 with 30% aqueous sodium hydroxide solution. The temperature was controlled at 21°C, and then adsorbed by macroporous resin, the adsorption flow rate was set at 1.1BV / h, and the resin column capacity was 12L. Then analyze with 3% sodium bicarbonate aqueous solution at a rate of 1.2BV / h, and control the temperature at 21°C. The analyzed feed liquid is purified by ultrafiltration, the pressure of ultrafiltration is 4.2bar, and the flux is 48LMH. The mixed dialysate after ultrafiltration is then concentrated by nanofiltration. The pressure of nanofiltration is 17bar, and the flux is 22LMH. 4 L of concentrated solution was obtained, the concentration was 5.57 g / L, and the yield was 88.4%. The concentrated solution was directly reused until the 7-ADCA diexpannic acid was dissolved to replace 4 L of dissolved water, and the final 7-ADCA yield increased by 0.80%.

Embodiment 3

[0042]Take 60L of 7-ADCA mother liquor with a concentration of 410ug / ml, and adjust the pH of the mother liquor to 6.5 with 30% aqueous sodium hydroxide solution. The temperature is controlled at 22°C, and then undergoes resin adsorption, the adsorption flow rate is 1.2BV / h, and the resin column capacity is 12L. Then analyze with 4% sodium bicarbonate aqueous solution at a rate of 1.5BV / h, and control the temperature at 22°C. The analyzed feed liquid is purified by ultrafiltration, the pressure of ultrafiltration is 4.4bar, and the flux is 50LMH. The mixed dialysate after ultrafiltration is then concentrated by nanofiltration. The pressure of nanofiltration is 20bar, and the flux is 25LMH. 4 L of concentrated solution was obtained, the concentration was 5.42 g / L, and the yield was 88.1%. The concentrated solution was directly reused until the 7-ADCA diexpannic acid was dissolved to replace 4 L of dissolved water, and the final 7-ADCA yield increased by 0.78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap