A kind of preparation method of dry-process octenyl succinic anhydride modified guar gum and the product prepared by the method

A technology of octenyl succinic anhydride and guar gum, which is applied in the field of preparation methods and products obtained by the method, can solve the problems of high content of water-insoluble matter, limited application of guar gum, difficult control of viscosity, etc., and achieve product performance Stable, good degree of substitution, easy to control viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

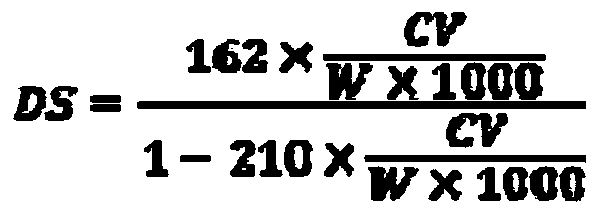

Image

Examples

preparation example Construction

[0019] The first aspect of the present invention provides a kind of preparation method of octenyl succinic anhydride modified guar gum, it is characterized in that, comprises the following steps:

[0020] (1) Add a certain amount of guar collagen powder and a certain amount of glidant to a stirrable sealed reaction vessel, fully stir to make it evenly mixed;

[0021] (2) Vacuumize repeatedly, fill nitrogen 3 to 5 times, then slowly spray a certain amount of sodium hydroxide or potassium hydroxide aqueous solution with a mass fraction of 3% into the reaction vessel, raise the temperature to 40°C-50°C, and alkalize 30-70 minutes;

[0022] (3) Add a certain amount of octenyl succinic anhydride and mix evenly, and heat up to 50-60°C, and react at constant temperature for 2-4 hours;

[0023] (4) drying, pulverizing, and passing through a 200-mesh sieve to obtain a finished product.

[0024] In a preferred embodiment, in the method, the step (2) is: slowly injecting a certain amou...

Embodiment 1

[0031] 1. Add 200g of guar collagen powder and 8g of sodium chloride as a flow aid into a stirrable sealed reaction vessel, stir well to make it evenly mixed.

[0032] 2. Vacuum repeatedly, fill with nitrogen 3 to 5 times, then slowly spray 1.0 g of 3% sodium hydroxide aqueous solution into the reaction vessel, raise the temperature to 40°C-50°C, and alkalize for 30 to 70 minutes.

[0033] 3. Add 80g of octenyl succinic anhydride and mix evenly, raise the temperature to 50°C, and react at constant temperature for 2-4 hours.

[0034] 4. Dried, crushed, and passed through a 200-mesh sieve to obtain a finished product.

Embodiment 2

[0036] 1. Add 200g of guar collagen powder and 4g of sodium sulfate as a flow aid into a stirrable sealed reaction vessel, stir well to make it evenly mixed.

[0037] 2. Vacuum repeatedly, fill with nitrogen 3 to 5 times, then slowly spray 1.0 g of 3% sodium hydroxide aqueous solution into the reaction vessel, raise the temperature to 40°C-50°C, and alkalize for 30 to 70 minutes.

[0038] 3. Add 60g of octenyl succinic anhydride and mix evenly, and raise the temperature to 50°C, and react at constant temperature for 2-4 hours.

[0039] 4. Dried, crushed, and passed through a 200-mesh sieve to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com