Method for preparation of organic-inorganic hybrid hollow nanosphere by ultrasound

A nanosphere and inorganic technology, which is applied in the field of preparation of organic-inorganic hybrid hollow nanospheres, can solve the problems of prolonged preparation time, inability to meet the requirements, and achieve the effects of simple system, short time consumption and large output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

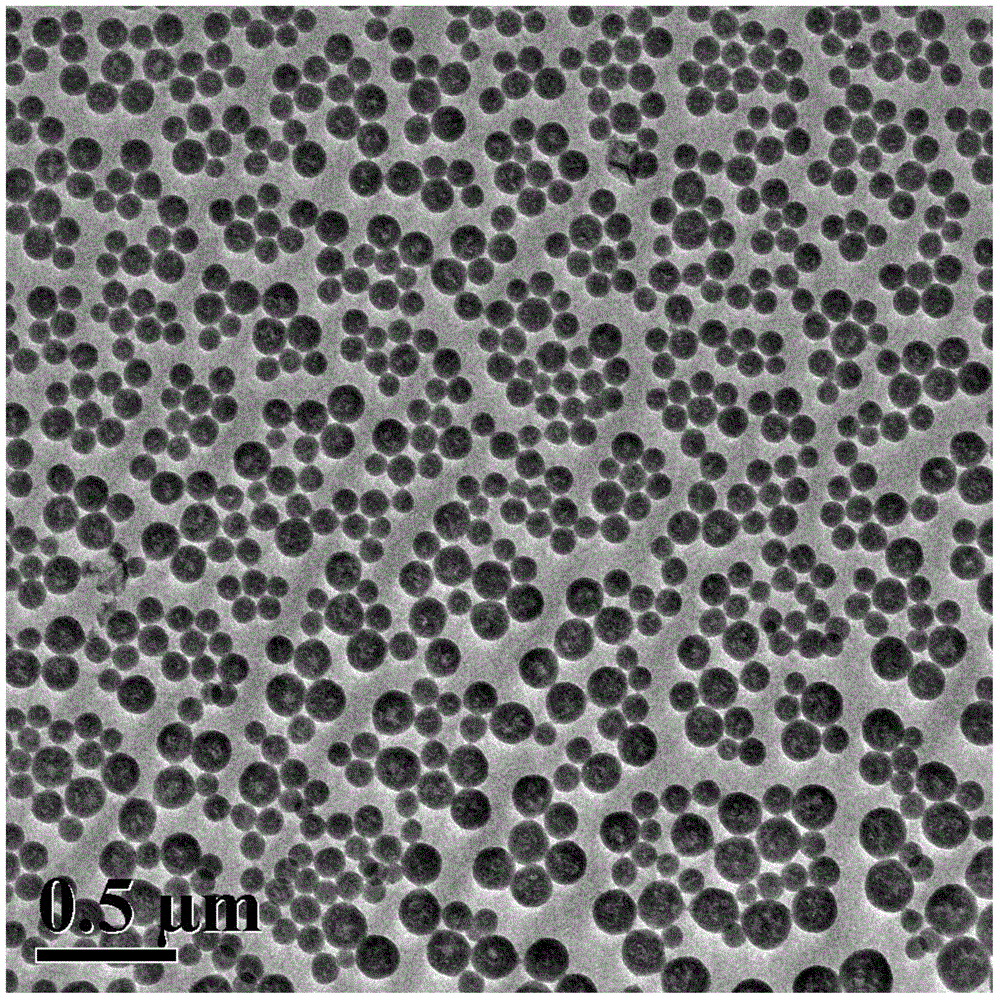

[0051] The raw materials are 3-methacryloyloxypropyltrimethoxysilane (TPM), isoamyl acetate, ammonia water and water, and the initiator is potassium persulfate. At room temperature, take 40 mL of pure water and adjust its pH value to 10 with ammonia water. Subsequently, 0.2 mL of TPM and 0.6 mL of isoamyl acetate were added to the above system, and ultrasonic (100 MHz) was performed for 15 min at room temperature. Afterwards, nitrogen was passed to exhaust oxygen for 30 minutes, and the temperature was raised to 70° C., and 10 mg of potassium persulfate was added to initiate polymerization, and the polymerization reaction continued for 12 hours. The obtained emulsion is centrifuged and washed three times with ethanol to obtain organic-inorganic hybrid hollow nanospheres.

[0052] The above-mentioned organic-inorganic hybrid hollow nanospheres were dispersed in ethanol to make a transmission electron microscope sample, and the morphology of the particles was observed. Such as...

Embodiment 2

[0055] The raw materials are 3-methacryloyloxypropyltrimethoxysilane (TPM), isoamyl acetate, ammonia water and water, and the initiator is potassium persulfate. At room temperature, take 60 mL of pure water and adjust its pH value to 9.4 with ammonia water. Subsequently, 0.2 mL of TPM and 0.6 mL of isoamyl acetate were added to the above system, and ultrasonic (100 MHz) was performed for 15 min at room temperature. Afterwards, nitrogen was passed to exhaust oxygen for 30 minutes, and the temperature was raised to 70° C., and 10 mg of potassium persulfate was added to initiate polymerization, and the polymerization reaction continued for 10 hours. The obtained emulsion is centrifuged and washed three times with ethanol to obtain organic-inorganic hybrid hollow nanospheres.

[0056] The above-mentioned organic-inorganic hybrid hollow nanospheres were dispersed in ethanol to make a transmission electron microscope sample, and the morphology of the particles was observed. and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com