High-melt-strength impact-resistant polypropylene foaming material and preparation method thereof

A high-melt-strength, foaming material technology, applied in the field of polymers, can solve the problems of material melting and extrusion difficulties, difficulty in uniform and fine cells, and decrease in melt strength, etc., to achieve controllable expansion ratio and smooth surface The effect of good degree and high foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0091] This preparation example is used to illustrate the polypropylene provided by the present invention and its preparation method.

[0092] The propylene polymerization reaction is carried out on a polypropylene unit, and the main equipment of the unit includes a prepolymerization reactor, a first loop reactor, a second loop reactor and a third gas phase reactor. The polymerization method and steps are as follows.

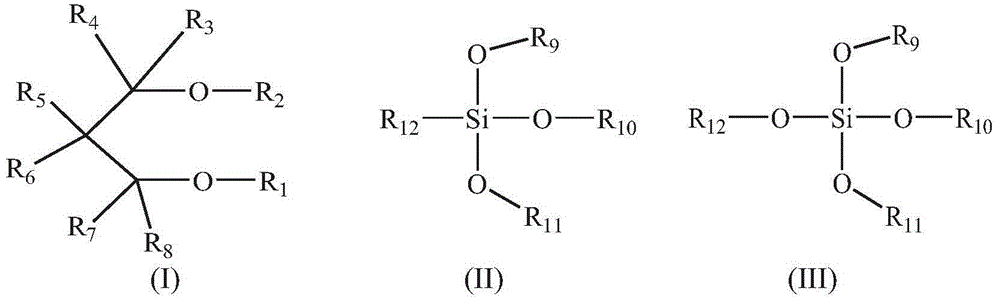

[0093] (1) Prepolymerization reaction

[0094] The main catalyst (DQC-401 catalyst, provided by Sinopec Catalyst Company Beijing Aoda Branch), the cocatalyst (triethylaluminum), the first external electron donor (dicyclopentyl-dimethoxysilane, DCPMS) after 6 ℃, 20min after pre-contact, continuously into the continuous stirred tank prepolymerization reactor for prepolymerization reactor. The flow rate of triethylaluminum (TEA) entering the prepolymerization reactor is 6.33g / hr, the flow rate of dicyclopentyl-dimethoxysilane is 0.3g / hr, the flow rate of the main...

preparation example 2

[0102] This preparation example is used to illustrate the polypropylene provided by the present invention and its preparation method.

[0103] The catalyst used in Preparation Example 2, pre-complexation, and polymerization process conditions are the same as those in Preparation Example 1. The difference with Preparation Example 1 is: the amount of hydrogen in the second reactor in the second stage becomes 13000ppm, and the hydrogen in the second step gas phase reactor 2 / (C 2 +C 3 ) was adjusted to 0.49 (mol / mol). The first external electron donor was changed to methyl-isopropyl-dimethoxysilane (MIPMS), and the amount added remained unchanged. The obtained polymer analysis results and polymer physical properties are listed in Table 1 and Table 2.

[0104]

[0105] From the results shown in Table 1 and Table 2, it can be seen that the polypropylene material prepared by the method of the present invention has high melt strength and high notched impact strength. Therefor...

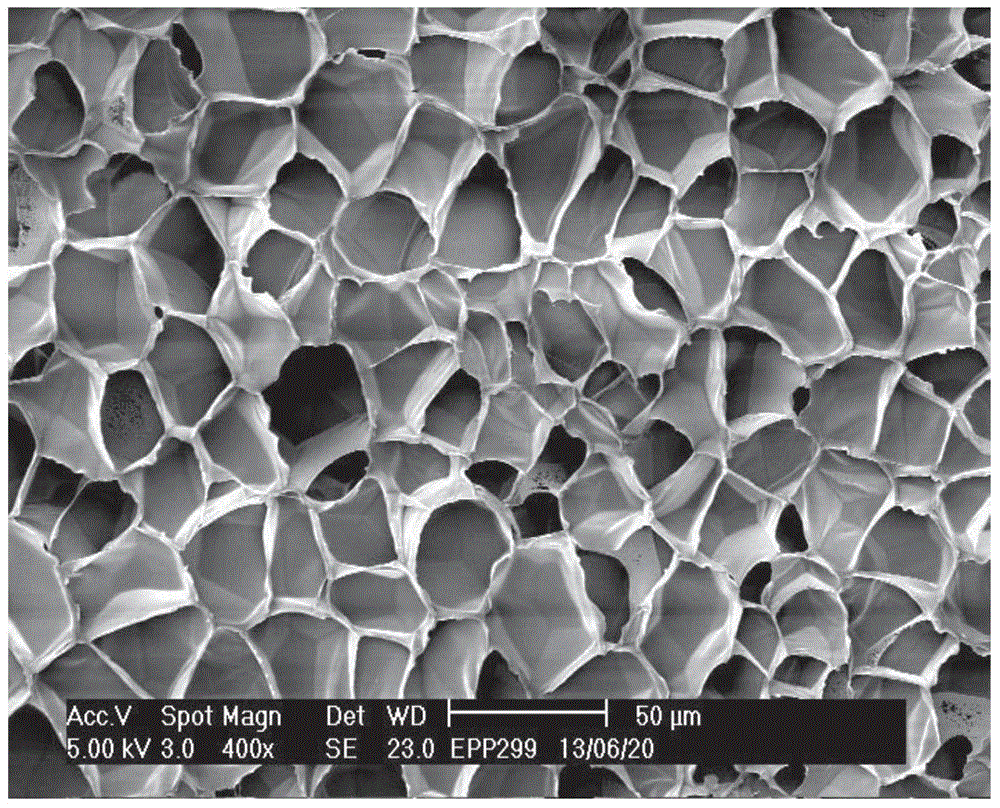

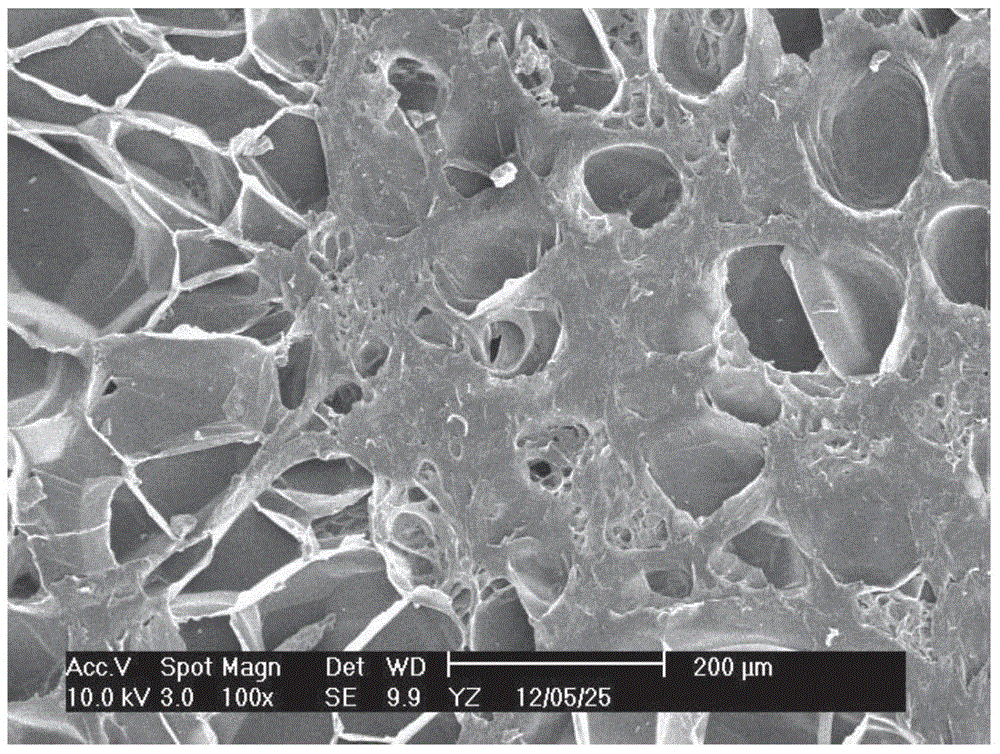

Embodiment 1

[0108] The polypropylene particles prepared in Preparation Example 1 were kneaded by a twin-screw extruder, shaped by a die, cooled and cut off to make a 20cm*20cm*1cm polypropylene board to be expanded. The mold installed between the molding presses was heated up to 157° C., the polypropylene plate was put into it, the molding presses were closed, and the molds were sealed. Feed 12MPa supercritical carbon dioxide into the mold to make the supercritical carbon dioxide diffuse into the polypropylene matrix at 157°C and 12MPa. After 45 minutes of saturation, the diffusion equilibrium is reached, and the pressure in the mold is reduced to 4MPa through the pressure relief valve, and then the mold is opened to release the pressure and foam, the foam board pops up, cooled and shaped, and the outer dimension is 60.3cm*60.3cm*3.0m Polypropylene foam sheet. Test its foaming ratio, and analyze its internal cell shape by scanning electron microscope. Its performance is shown in Table 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com