Modified nano composite silicon rubber seal ring and preparation thereof

A nano-composite and sealing ring technology, applied in the field of sealing rings, can solve the problems of reducing the mechanical properties of silicone sealing rings, affecting the application of sealing materials, and reducing sealing performance, so as to achieve the effects of increasing air tightness, increasing toughness and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

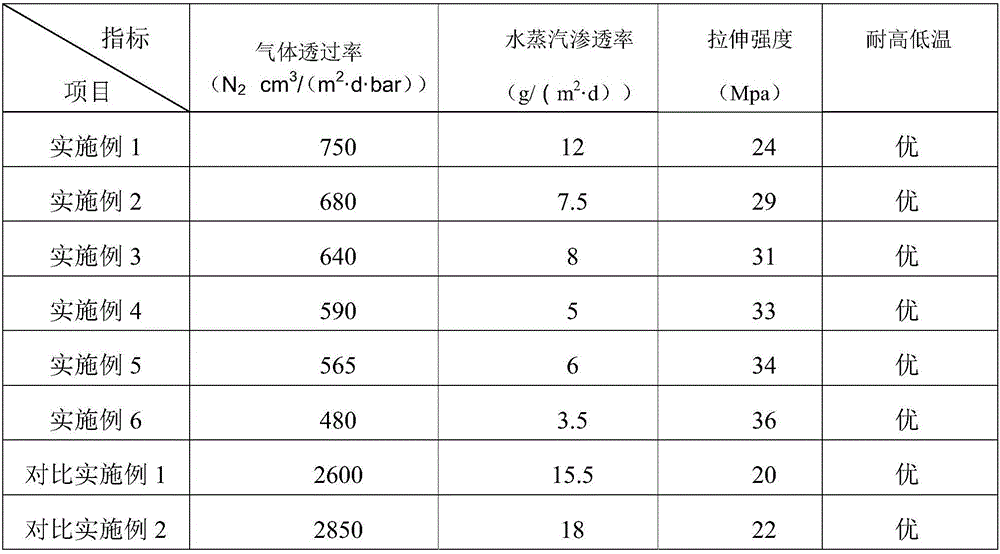

Examples

Embodiment 1

[0029] Step 1) modification of nano-additives: select 5-10 layers of white graphene to soak in 0.1% oleylamine aqueous solution for 24 hours, obtain modified white graphene additives after centrifugation and vacuum drying;

[0030] Step 2) raw rubber mixing: Weigh 100 parts of methyl vinyl silicone rubber with a vinyl molar percentage of 0.25%, 15 parts of hydroxyl-terminated polydimethylsiloxane, and 3 parts of silane coupling agent in parts by weight KH-570, 0.1 part of modified white graphene additive and 30 parts of carbon black prepared in step 1) were added to the internal mixer for mixing in turn, the mixing temperature was 90°C, and the mixing time was 50 minutes; then passed through the twin-screw The extruder is extruded at a temperature of 120°C to obtain a raw rubber compound;

[0031] Step 3) Vulcanization molding: Weigh 100 parts by weight of the raw rubber compound obtained in step 2) and 3 parts of di-tert-butyl peroxide, mix and disperse evenly at room tempera...

Embodiment 2

[0033] Step 1) modification of nano-additives: select 5-10 layers of white graphene to soak in 0.1% oleylamine aqueous solution for 24 hours, obtain modified white graphene additives after centrifugation and vacuum drying;

[0034] Step 2) raw rubber mixing: weigh 100 parts by weight of methyl vinyl silicone rubber with a vinyl molar percentage of 0.25%, 8 parts of hydroxyl-terminated polydimethylsiloxane, and 1 part of silane coupling agent KH-570, 0.5 parts of modified white graphene additives and 20 parts of carbon black prepared in step 1) were successively added to the internal mixer for mixing, the mixing temperature was 60°C, and the mixing time was 20min; The screw extruder is extruded at a temperature of 180°C to obtain raw rubber compound;

[0035] Step 3) Vulcanization molding: Weigh 100 parts by weight of the raw rubber compound obtained in step 2) and 1.5 parts of di-tert-butyl peroxide. In the mold, the modified nano-composite silica gel sealing ring is obtained...

Embodiment 3

[0037] Step 1) Modification of nano-additives: disperse graphene with 5-10 layers in a concentration of 0.3mg / ml polyvinylpyrrolidone aqueous solution for 10 hours, and obtain modified graphene additives after centrifugation and vacuum drying;

[0038] Step 2) raw rubber mixing: Weigh 100 parts of methyl vinyl silicone rubber with a vinyl molar percentage of 0.25%, 15 parts of hydroxyl-terminated polydimethylsiloxane, and 3 parts of silane coupling agent in parts by weight KH-570, 0.1 parts of modified graphene additives and 30 parts of carbon black prepared in step 1) were added to the internal mixer and mixed in sequence. The mixing temperature was 90°C and the mixing time was 50 minutes; then passed through twin-screw extrusion The extruder is extruded at a temperature of 120°C to obtain a raw rubber compound;

[0039] Step 3) Vulcanization molding: Weigh 100 parts by weight of the raw rubber compound obtained in step 2) and 3 parts of di-tert-butyl peroxide, mix and disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com