Oil base drilling cutting cleaning fluid and cleaning method for oil base drilling cuttings

A technology for oil-based drilling cuttings and cleaning fluid, applied in the field of oil-based drilling cuttings cleaning fluid and oil-based drilling cuttings cleaning, can solve problems such as complex process and equipment corrosion, achieve simple operation, low cost, and reduce oil-water interfacial tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

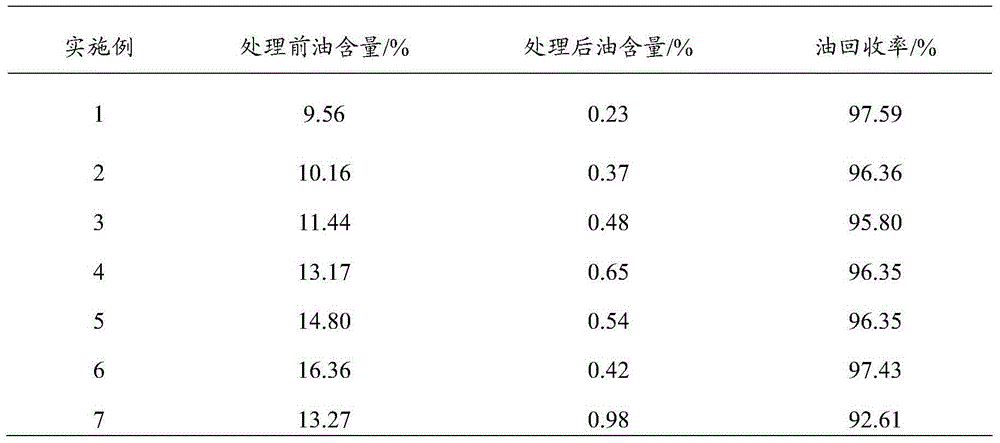

Examples

Embodiment 1

[0040]Put 1000g of oil-based drill cuttings in an oil field in a container with stirring facilities, add 16g of demulsifier 1231 produced by Shanghai Chengguan Biotechnology Co., Ltd. under constant stirring at a speed of 200rpm, and stir for 3 minutes; Sodium acyl-N-methyl taurate and 1000 g of water were continuously stirred for 5 minutes to obtain a mixture; the mixture was centrifuged at 2500 rpm for 5 minutes to obtain an upper oil phase, an intermediate water phase and a lower solid phase. The separated intermediate aqueous phase can be used for the next round of cleaning of oil-based cuttings.

Embodiment 2

[0042] Put 1000g of oil-based drilling cuttings in a certain oil field in a container with stirring facilities, add 20g of demulsifier 1631 produced by Shanghai Chengguan Biotechnology Co., Ltd. under constant stirring at a speed of 300rpm, and stir for 2 minutes; then add 8g of Sodium alkylbenzene sulfonate and 1500 g of water were continuously stirred for 10 minutes to obtain a mixture; the mixture was centrifuged at 3000 rpm for 5 minutes to obtain an upper oil phase, an intermediate water phase and a lower solid phase. The separated intermediate aqueous phase can be used for the next round of cleaning of oil-based cuttings.

Embodiment 3

[0044] Put 1000g of oil-based drill cuttings in an oil field in a container with stirring facilities, and add 18g of demulsifier 1831 produced by Shanghai Chengguan Biotechnology Co., Ltd. under constant stirring at a speed of 250rpm, and stir for 4 minutes; then add 7g of sorbitol Oleate and 1200g of water were stirred for 4 minutes to obtain a mixture; the mixture was centrifuged at 3000 rpm for 8 minutes to obtain an upper oil phase, an intermediate water phase and a lower solid phase. The separated intermediate aqueous phase can be used for the next round of cleaning of oil-based cuttings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com