Seepage-proof construction method for strata developed in karst caves under overburden

A technology of under-covering and construction methods, which is applied in infrastructure engineering, construction, etc., can solve the problems of mechanical use efficiency, low labor efficiency, complex construction technology and construction process, and large grouting diffusion range, so as to reduce accidents in holes , Avoid long-distance transportation, good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

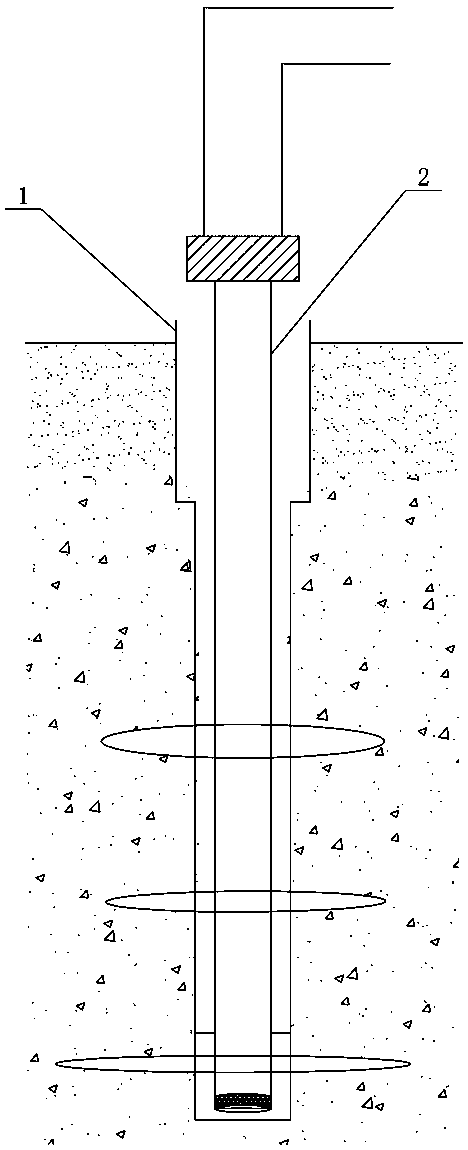

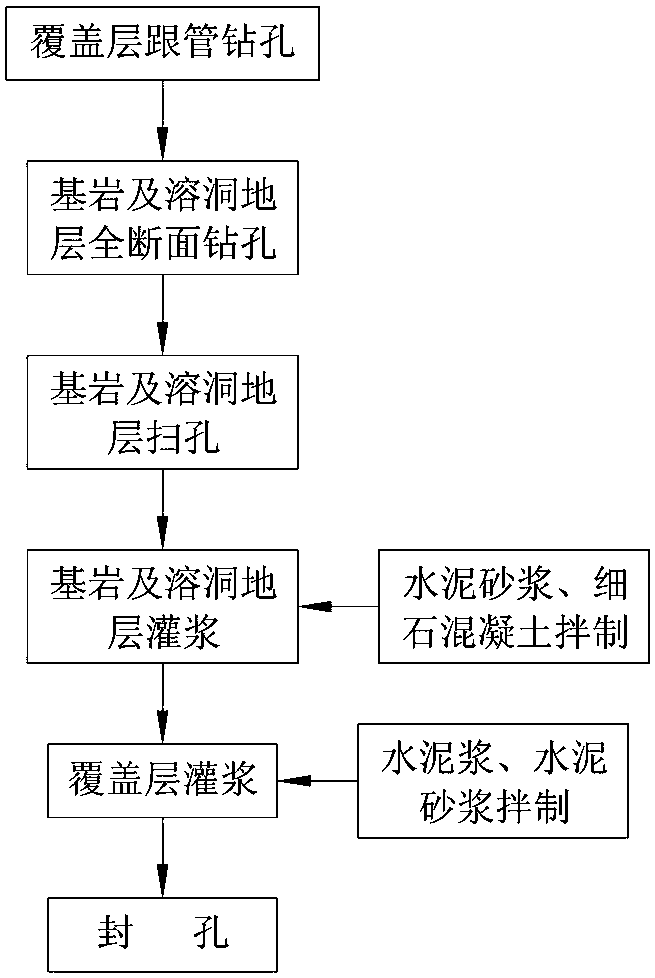

[0025] Such as figure 1 with figure 2 Shown, a kind of embodiment of the anti-seepage construction method of karst cave development formation under the overburden of the present invention may further comprise the steps:

[0026] S1: Overburden and pipe drilling: use percussion drill eccentric drilling tools to drill in clay and strong weathered overburden, and use casing 1 to follow up and protect the hole wall;

[0027] S2: Full-section drilling in bedrock and karst cave formations: pull out the drill and replace drilling tools, use percussion drilling tools to conduct full-section drilling in bedrock and karst cave formations, and end when the designed hole depth is reached;

[0028] S3: Sweeping holes in bedrock and karst cave formations: pull out the drill and replace the drill pipe and drill bit, use the percussion drilling ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com