A gas chromatograph detector

A gas chromatography and gas chromatography column technology, applied in the field of gas chromatography detectors, can solve the problems of not being able to truly and timely reflect the temperature rise of catalytic combustion, unable to meet the needs of gas chromatography detection, long sensor response time, etc., and achieve noise reduction. , the effect of complete reaction and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

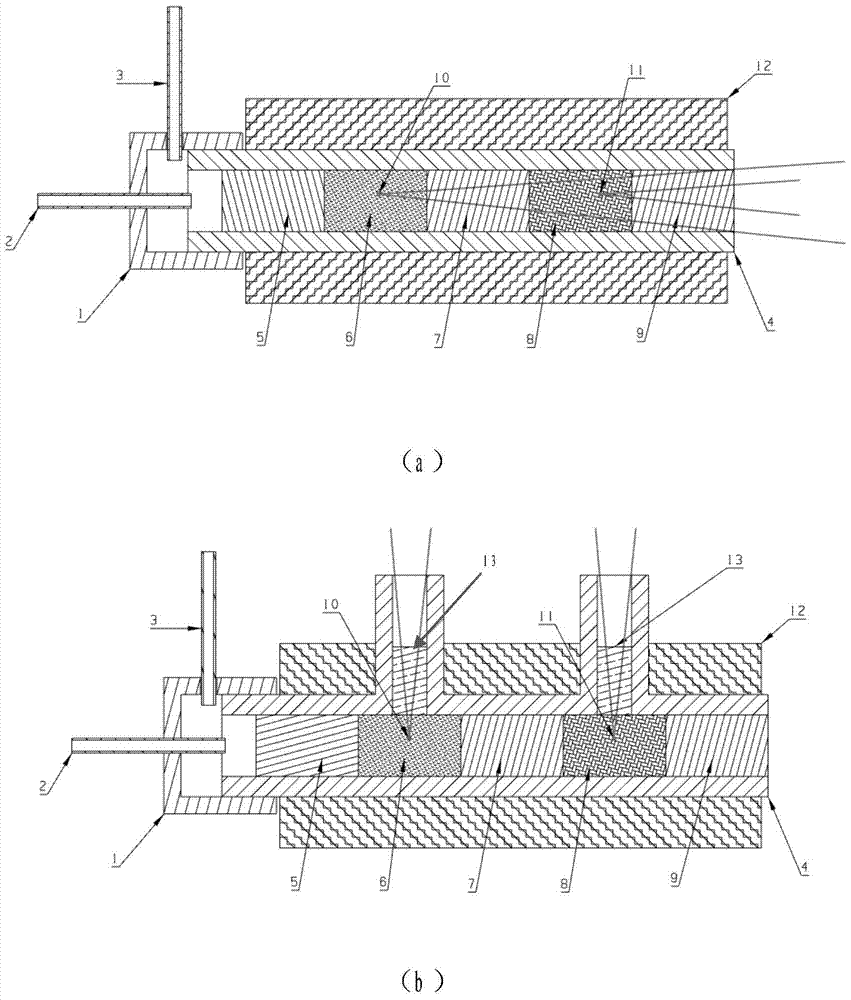

[0024] Assemble a gas chromatograph detector such as figure 1 As shown in (a), consists of heating block (12), gas pipe (4), reference packing (6), first temperature measuring element (10), second temperature measuring element (11), catalyst packing (8) , a first heat insulating layer (5), a second heat insulating layer (7), a cavity (1), and a signal processing system; the cavity (1) is a cylindrical structure, and the side wall of the cylindrical structure has a The interface on the side wall is connected to the makeup gas line (3), one end of the cylinder is sealed and has an interface to connect to the gas chromatography column (2), and the other end of the cylinder is open to connect to the gas line pipe (4), the gas chromatography column ( 2) It is coaxial and communicated with the gas pipeline (4), and the gas pipeline (4) is filled with the first heat insulation layer (5), the reference filler (6), the second heat insulation layer (1) from one end of the cavity (1) La...

Embodiment 2

[0027] like figure 1 As shown in (b), on the basis of the gas chromatographic detector described in Embodiment 1, the gas line pipe 4 is respectively provided with openings in the two packing areas, and the wires of the first temperature measuring element 10 and the second temperature measuring element 11 are respectively Lead out from two openings, and seal and fix with sealant 13, and sealant 13 selects inorganic glue.

Embodiment 3

[0029] On the basis of the gas chromatographic detector described in Example 1, the catalyst packing 8 is changed to gold-loaded titanium dioxide particles, with a loading of 35 mg, wherein the gold loading is 10% (w / w), and the detector is used for 130 ℃ selective detection of methanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com