Polyamide composition applicable to high-power LED

A polyamide composition and high-power technology, applied in the field of polyamide compositions for high-power LEDs, can solve the problems of poor yellowing resistance, insufficient material toughness, poor dimensional stability, etc., and achieve low water absorption and dimensional stability. Good, high viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Preparation of semi-aromatic resin PA12T

[0057] 1) Add 4980g (30mol) of terephthalic acid, 6200g (31mol) of dodecyl diamine, and 33g of benzoic acid in sequence into a 20L autoclave equipped with magnetic coupling stirring, condenser, exhaust port, and pressure explosion-proof port , 33g sodium phosphate and 8kg deionized water;

[0058] 2) After reacting at 120°C for 5 hours, the temperature was raised to 220°C at a constant rate, and the pressure was kept constant for 10 hours;

[0059] 3) Reduce the pressure in the autoclave to 0.4MPa within 1 hour;

[0060] 4) Heat the high-purity nitrogen gas to 310°C and evenly pass it into the reactor for 3 hours, and discharge the material to obtain the required semi-aromatic polyamide (A) (PA12T). At 25°C, in 96% concentrated sulfuric acid, the measured reduced viscosity is 2.14dl / g.

[0061] Among them, PA6T / 66 resin: HTN 501 resin purchased from DuPont, USA; PA9T resin: N1000A resin purchased from Kuraray, Japan; PCT res...

Embodiment 1~5 and comparative example 1~3

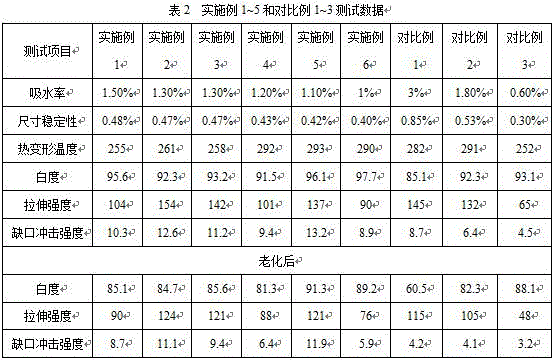

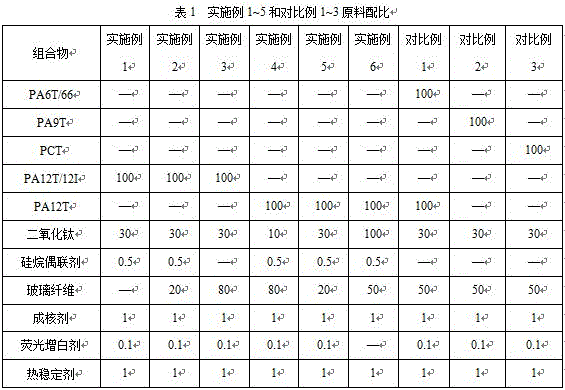

[0063] The resin was first dried in a vacuum oven at 120°C for 4 hours, and then mixed according to the ratio listed in Table 1. Mix the other materials except white dye and enhancer evenly and feed them into the twin-screw extruder from the main hopper, add the enhancer from the first side feeder, and add the white dye from the second side feeder. After uniform kneading in the extruder, extrude, water-cool the strands, and then use a pelletizer to cut into columnar particles to obtain the desired polyamide composition. Then the polyamide composition was dried in a vacuum drying oven at 120° C. for 4 hours, and various standard samples were made into various standard samples with an injection molding machine for various performance tests. The test results are listed in Table 2.

[0064]

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com