Method for liquid-solid-solution synthesis of rare earth doped fluorine zinc potassium luminescent material

A luminescent material and rare earth doping technology, which is applied in the field of liquid-solid-solution synthesis of rare earth-doped fluorine-zinc-potassium luminescent materials, which can solve the problems of limited rare earth resources and high cost of rare earth substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

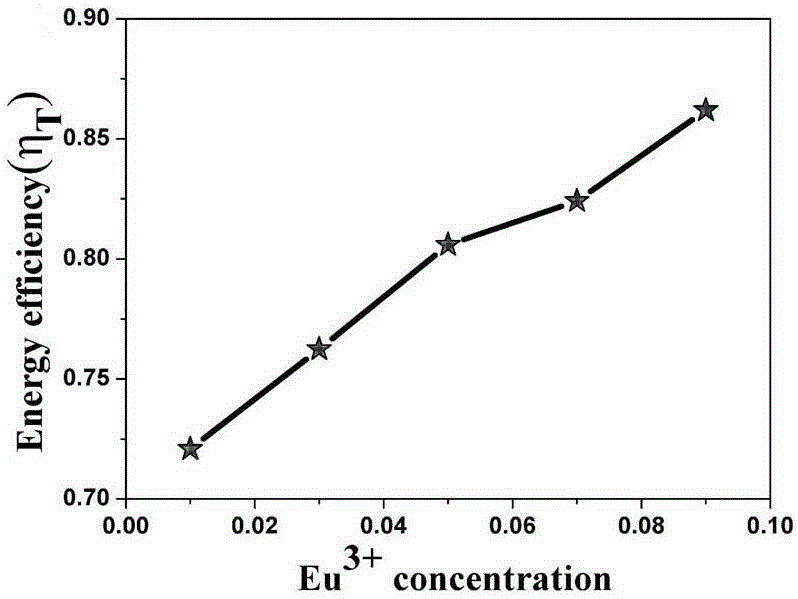

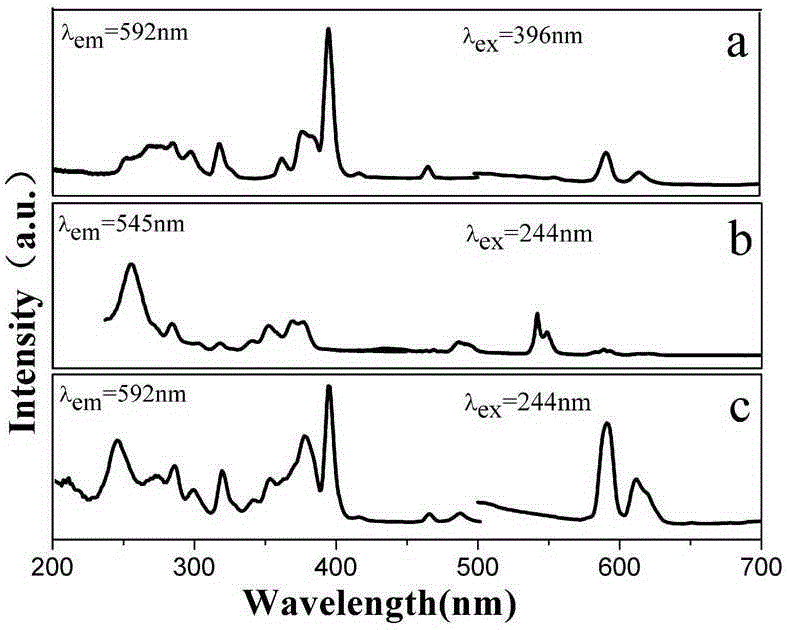

[0021] Example 1 A preparation method of europium-doped fluorine-zinc-potassium micron luminescent powder, the product chemical formula is KZnF 3 : 0.07 Eu 3+ ;

[0022] 1) Accurately weigh 0.5 g KOH into a 50 mL Erlenmeyer flask filled with 10 mL deionized water and dissolve it for use;

[0023] 2) Add 15 mL of n-butanol and 5 mL of oleic acid and continue to stir at a constant speed for 20 min to form a yellow oily liquid and obtain Solution A;

[0024] 3) Weigh Zn(NO 3 ) 2 ·6H 2 O 0.2767 g, at the same time measure the concentration of 0.5 mol L -1 Eu(NO 3 ) 3 Solution 0.14 mL was mixed and added to solution A, and the resulting solution was stirred with a stirrer for 30 min to form a slightly yellow emulsion;

[0025] 4) Add 0.2964 g NH to the solution 4 F continued to stir for 1 h to obtain a white emulsion mixed solution;

[0026] 5) Put the stirred milky white solution into a 50 mL polytetrafluoroethylene reactor, and continue heating at 120 °C for 48 h; ...

Embodiment 2

[0030] Example 2A preparation method of terbium-doped fluorine-zinc-potassium micron luminescent powder, the product chemical formula is KZnF 3 : 0.05Tb 3+ ;

[0031] 1) Accurately weigh 0.5 g KOH into a 50 mL Erlenmeyer flask filled with 10 mL deionized water and dissolve it for use;

[0032] 2) Add 15 mL of n-butanol and 5 mL of oleic acid and continue to stir at a constant speed for 20 min to form a yellow oily liquid and obtain Solution A;

[0033] 3) Weigh Zn(NO 3 ) 2 ﹒ 6H 2 O 0.2826 g, at the same time measure the concentration of 0.1 mol L -1 Tb(NO 3 ) 3 0.5 mL of the solution was mixed and added to solution A, and the resulting solution was stirred with a stirrer for 30 min to form a uniform yellow solution;

[0034] 4) Add 0.2964 g NH to the solution 4 F continued to stir for 1 h to obtain a white emulsion mixed solution;

[0035] 5) Put the stirred milky white solution into a 50 mL polytetrafluoroethylene reactor, and continue heating at 120 °C for 48 ...

Embodiment 3

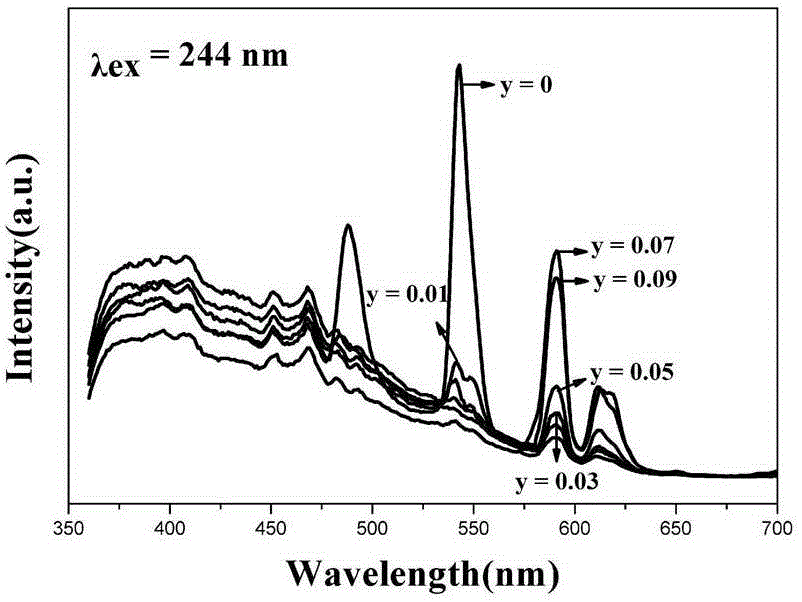

[0039] Example 3 A preparation method of europium / terbium doped cerium lanthanum micron luminescent powder, the product chemical formula is KZnF 3 : 0.05 Tb 3+ , 0.07Eu 3+ ;

[0040] 1) Accurately weigh 0.5 g KOH into a 50 mL Erlenmeyer flask filled with 10 mL deionized water and dissolve it for use;

[0041] 2) Add 15 mL of n-butanol and 5 mL of oleic acid and continue to stir at a constant speed for 20 min to form a yellow oily liquid and obtain Solution A;

[0042] 3) Weigh Zn(NO 3 ) 2 ·6H 2 O 0.2618 g, at the same time measure the concentration of 0.1 mol L -1 Tb(NO 3 ) 3 Solution 0.5 mL and concentration 0.5 mol L -1 Eu(NO 3 ) 3 Solution 0.14 mL was mixed and added to solution A, and the resulting solution was stirred with a stirrer for 30 min to form a uniform yellow solution;

[0043] 4) Add 0.2964 g NH to the solution 4 F continued to stir for 1 h to obtain a white emulsion mixed solution;

[0044] 5) Put the stirred milky white solution into a 50 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com