Biomass pyrolysis-reforming hydrogen production method

A biomass pyrolysis and reforming hydrogen production technology, applied in the energy field, can solve the problems of low energy density, low efficiency, and increase the complexity of the hydrogen production process of biomass raw materials, so as to alleviate the impact of the environment and energy, and achieve high-efficiency production. The effect of hydrogen efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

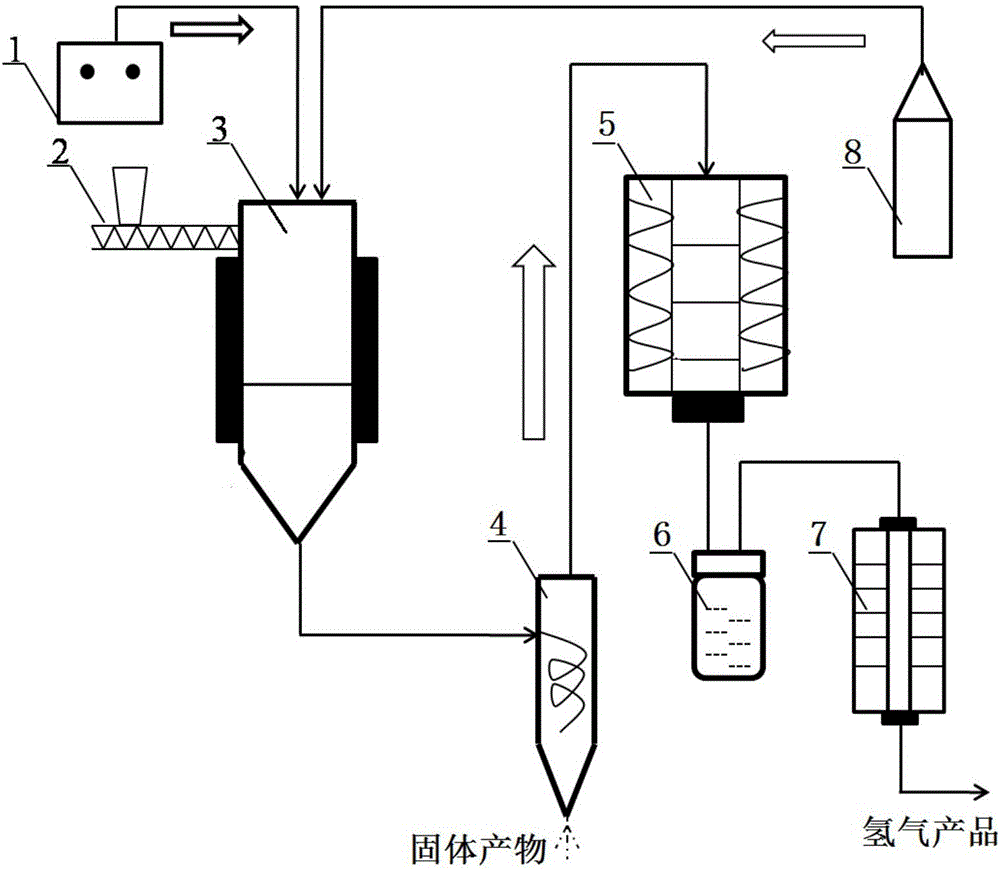

[0041] Biomass pyrolysis-reforming hydrogen production on wheat straw, the method is as follows:

[0042] (1) Pretreat the biomass raw material. The pretreatment process is to first crush the biomass raw material into particles with a particle size of 0.5mm, then place the biomass raw material in an oven, and dry it at 80°C. Make the water content of the biomass raw material reach 6wt%;

[0043] (2) Transport the pretreated biomass raw material into the fixed-bed pyrolysis reactor at a feed rate of 5Kg / h with a screw feeder, at a temperature of 400°C, an inert carrier (nitrogen) flow rate of 0.6L / min, The pyrolysis is carried out under the condition of water vapor flow rate of 0.1L / min. The pyrolysis uses HZSM-5 catalyst, the usage amount is 50g, and the pyrolysis product enters the high-temperature cyclone separator to separate the gas phase product and the solid phase product, and the solid residue and ash Part is discharged from the bottom of the high-temperature cyclone s...

Embodiment 2

[0048] Biomass pyrolysis-reforming hydrogen production on traditional Chinese medicine dregs, the method is as follows:

[0049] (1) Pretreatment of the biomass raw material, the pretreatment process is firstly pulverizing the biomass raw material into particles with a particle size of 1.5mm, and then placing the biomass raw material in an oven and drying it at 105°C, Make the water content of the biomass raw material reach 3wt%;

[0050] (2) Transport the pretreated biomass raw material into the fluidized bed pyrolysis reactor at a feed rate of 1Kg / h with a screw feeder. , water vapor flow rate 0.2L / min, ratio of fluidized bed spout gas to fluidization gas is 5, fluidized state operating speed is 0.5m / s under the condition of pyrolysis, pyrolysis uses Co 3 o 4 Catalyst, the usage amount is 60g, the pyrolysis product enters the high-temperature cyclone separator to separate the gas-phase product and the solid-phase product, the solid residue and ash are discharged from the b...

Embodiment 3

[0055] Biomass pyrolysis-reforming hydrogen production on traditional Chinese medicine dregs, the method is as follows:

[0056] (1) Pretreat the biomass raw material. The pretreatment process is to first crush the biomass raw material into particles with a particle size of 2.0mm, then place the biomass raw material in an oven, and dry it at 95°C. Make the water content of the biomass raw material reach 4wt%;

[0057] (2) Transport the pretreated biomass raw material into the fluidized bed pyrolysis reactor at a feed rate of 2Kg / h with a screw feeder, at a temperature of 600°C and an inert carrier (nitrogen) flow rate of 0.6L / min , water vapor flow rate 0.3L / min, ratio of fluidized bed spout gas to fluidization gas is 5, fluidized state operating speed is 0.5m / s for pyrolysis, pyrolysis uses attapulgite catalyst, using Amount of 100g, the pyrolysis product enters the high temperature cyclone separator to separate the gas phase product and the solid phase product, the solid re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com