Cobaltosic oxide @ sulfur cobalt acid nickel core shell nanoflower array, manufacturing method and application thereof

A technology of cobalt trioxide and nanoflowers, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of limiting the practical application of traditional capacitor materials, limited cycle life, and poor rate performance, reaching High reproducibility, high energy density and power density, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of cobalt tetraoxide nanometer material, comprising the following steps:

[0040] (1) Dissolve 0.476g of cobalt chloride hexahydrate, 0.300g of ammonium fluoride, and 0.600g of urea in 40mL of distilled water at room temperature under magnetic stirring conditions.

[0041] (2) The mixed solution is transferred to the reaction kettle. 2×3cm 2 After cleaning and treating nickel foams of large and small sizes, immerse them in the reactor, seal the reactor, and react at 120°C for 9 hours. After the reaction kettle was naturally cooled to room temperature, the nickel foam was taken out, washed several times with ethanol and distilled water respectively, and then dried in a drying oven at 60°C for 12 hours;

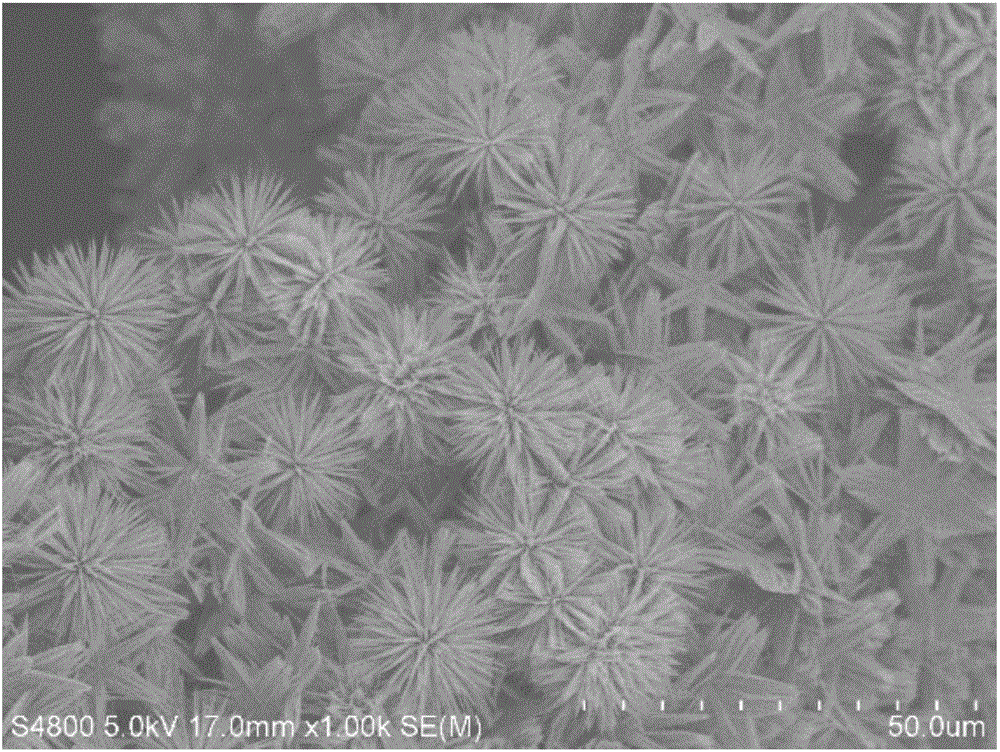

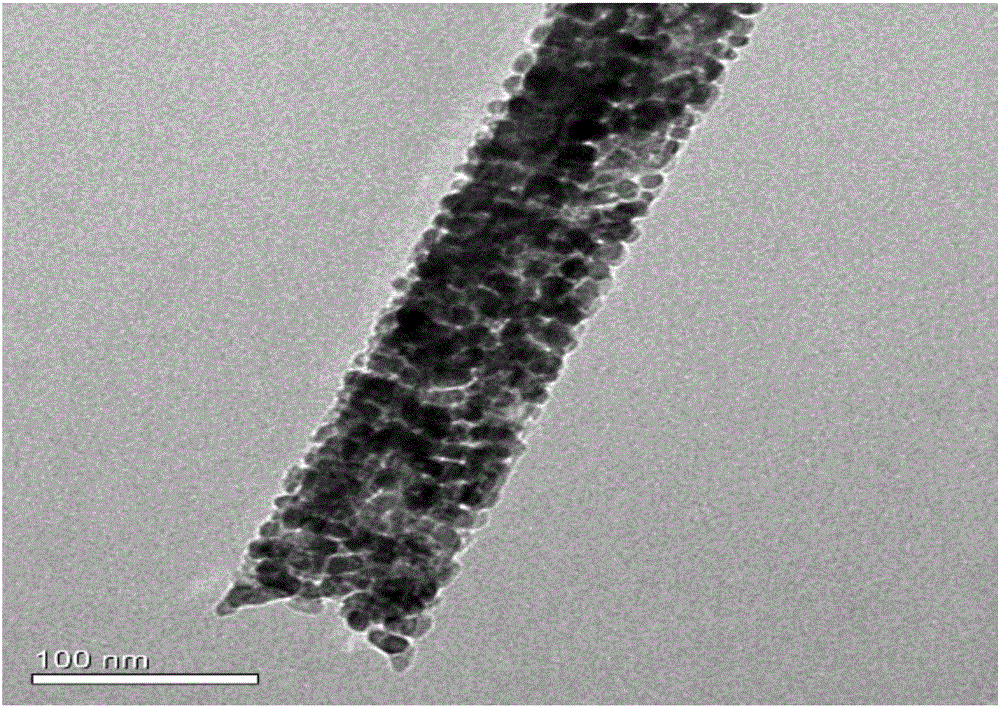

[0042] (3) Calcining the dried nickel foam at 300°C in an air atmosphere for 3 hours to obtain the precursor of cobalt tetraoxide nanoflowers, the morphology of which is as follows: figure 1 , figure 2 shown.

[0043] The cleaning method is: un...

Embodiment 2

[0046] A preparation method of cobalt, nickel composite nano flower array, comprising the following steps:

[0047] (1) Dissolve 0.476g of cobalt chloride hexahydrate, 0.300g of ammonium fluoride, and 0.600g of urea in 40mL of distilled water at room temperature under magnetic stirring conditions.

[0048] (2) The mixed solution is transferred to the reaction kettle. 2×3cm 2 After cleaning and treating nickel foams of different sizes, immerse them in the reactor, seal the reactor, and react at 120°C for 9 hours. After the reactor was naturally cooled to room temperature, the nickel foam was taken out and washed several times with ethanol and distilled water respectively.

[0049](3) Dissolve 0.291 g of nickel nitrate hexahydrate and 0.600 g of urea in 40 mL of distilled water at room temperature under stirring conditions. The mixed solution is transferred to the reaction kettle, the nickel foam after the first step of reaction is immersed in the reaction solution in the ket...

Embodiment 3

[0052] A preparation method of tricobalt tetroxide@sulfur cobaltate nickel core-shell nanoflower array, comprising the following steps:

[0053] (1) Dissolve 0.476g of cobalt chloride hexahydrate, 0.300g of ammonium fluoride, and 0.600g of urea in 40mL of double-distilled water at room temperature under magnetic stirring conditions.

[0054] (2) The mixed solution is transferred to the reaction kettle. 2×3cm 2 After cleaning and treating nickel foams of large and small sizes, immerse them in the reactor, seal the reactor, and react at 120°C for 9 hours. After the reactor was naturally cooled to room temperature, the nickel foam was taken out, and washed several times with ethanol and distilled water respectively.

[0055] (3) Dissolve 0.291 g of nickel nitrate hexahydrate and 0.600 g of urea in 40 mL of twice distilled water at room temperature under stirring conditions. The mixed solution is transferred to the reaction kettle, the nickel foam after the reaction in step (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com