Infant formula milk powder and making method thereof

An infant formula and infant formula technology are applied in the field of infant formula milk powder and its preparation to achieve the effects of improving absorption and bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

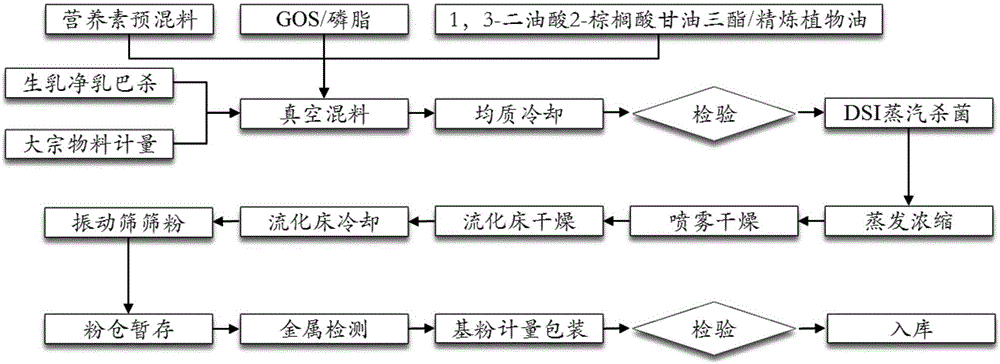

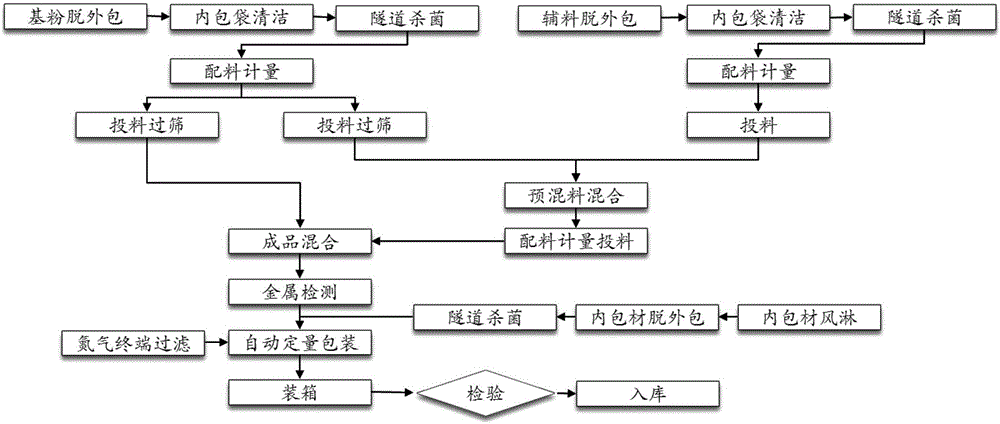

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 0-6 months infant formula milk powder (in 1 ton)

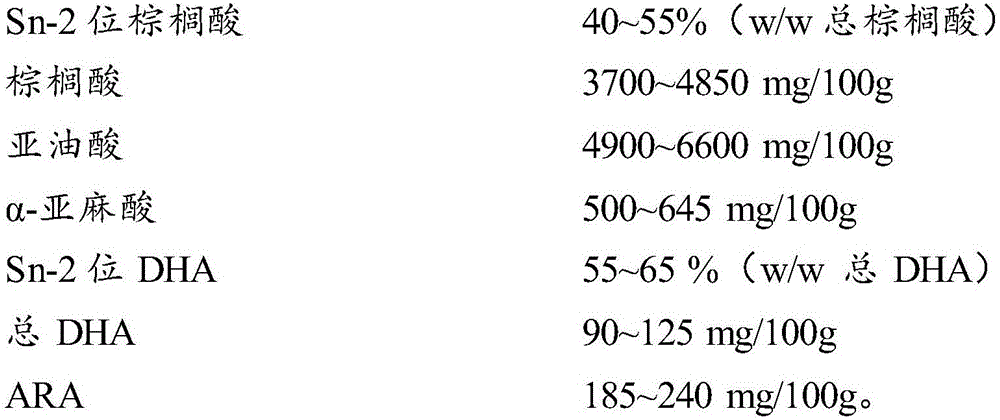

[0042] Take raw milk 1000kg, desalted whey powder 475kg, whole milk powder 115kg, 1,3-dioleic acid 2-palmitic acid triglyceride 100kg, refined vegetable oil 90kg, lactose 30kg, concentrated whey protein powder 12kg, oligomeric half Lactose 10kg, compound infant vitamin and mineral fortifier 18kg, nucleotide 0.4kg, phospholipid 4kg, DHA (sourced from tuna oil) 5.5kg, ARA 19kg. [Design value: 4500mg / 100g palmitic acid of which 48% (percentage of total palmitic acid) Sn-2 palmitic acid, 6000mg / 100g linoleic acid + 600mg / 100g α-linolenic acid + 110mg / 100g DHA of which 60% (percentage of total DHA) Sn-2 position DHA+210mg / 100g ARA. 】

Embodiment 2

[0043] Embodiment 2 6-12 months older infant formula milk powder (in 1 ton)

[0044] Raw milk 1000kg, desalted whey powder 400kg, whole milk powder 125kg, skim milk powder 115kg, 1,3-dioleic acid 2-palmitic acid triglyceride 80kg, refined vegetable oil 70kg, lactose 25kg, concentrated whey protein powder 16kg , 10kg of galacto-oligosaccharide, 10.5kg of compound infant vitamin and mineral fortifier, 0.4kg of nucleotide, 4kg of phospholipid, 5kg of DHA (sourced from tuna oil), 18kg of ARA. [Design value: 4200mg / 100g palmitic acid of which 47% (percentage of total palmitic acid) Sn-2 palmitic acid, 5500mg / 100g linoleic acid + 550mg / 100g α-linolenic acid + 100mg / 100g DHA of which 60% (percentage of total DHA) Sn-2 position DHA+200mg / 100g ARA. 】

Embodiment 3

[0045] Embodiment 3 Formula milk powder for infants aged 1-3: (calculated by 1 ton)

[0046] Raw milk 1000kg, desalted whey powder 400kg, skimmed milk powder 165kg, whole milk powder 100kg, 1,3-dioleic acid 2-palmitic acid triglyceride 80kg, refined vegetable oil 65kg, lactose 13kg, concentrated whey protein powder 10kg , 10kg of galacto-oligosaccharide, 8.5kg of compound infant vitamin and mineral fortifier, 0.4kg of nucleotide, 4kg of phospholipid, 5kg of DHA (sourced from tuna oil), 18kg of ARA. [Design value: 4000mg / 100g palmitic acid of which 45% (percentage of total palmitic acid) Sn-2 palmitic acid, 5200mg / 100g linoleic acid + 520mg / 100g α-linolenic acid + 100mg / 100g DHA of which 60% (percentage of total DHA) Sn-2 position DHA+200mg / 100g ARA. 】

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com