Method for separating iridium from base metal and other platinum family metals

A technology for platinum group metals and base metals, which is applied in the field of recovery, separation and purification of precious metals. It can solve the problems of difficult operation, low recovery rate of iridium, and large consumption of reagents, and achieve high recovery rate, low consumption of reagents and reduction of waste liquid. The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

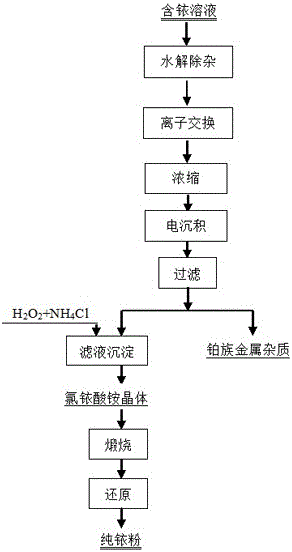

Image

Examples

Embodiment 1

[0029] A method for separating iridium from base metals and other platinum group metals, comprising the steps of:

[0030] (1) Hydrolysis of impurity removal: Slowly add 200 g of NaOH to 1000 ml of iridium solution containing a small amount of platinum, palladium, rhodium, ruthenium and base metal impurities such as Fe, Pb, Sn, Mg, Zn and stir at a speed of 60 r / min, stir for 20 min, adjust the pH value of the solution to 9.5, filter with a funnel and a suction filter bottle, and hydrolyze the base metal to form a hydroxide precipitate and remove it.

[0031] (2) Ion exchange: exchange the filtrate obtained by hydrolysis with cation resin three times to further remove base metal impurities to obtain a pure platinum group metal solution; the resin is a strong acid cation exchange resin with a flow rate of 200ml / min until the base metal The metal content is less than 0.0001g / L.

[0032] (3) Concentration: Concentrate the solution composed of iridium, platinum, palladium, rhodi...

Embodiment 2

[0037] A method for separating iridium from base metals and other platinum group metals, comprising the steps of:

[0038] (1) Hydrolysis of impurities: Slowly add 300 g of NaOH to 1500 ml of iridium solution containing a small amount of platinum, palladium, rhodium, ruthenium and base metal impurities such as Fe, Pb, Sn, Mg, Zn and stir at a speed of 70 r / min, stir for 30 min, adjust the pH value of the solution to 11, filter with a funnel and a suction filter bottle, so that the base metal is hydrolyzed to form a hydroxide precipitate and removed;

[0039] (2) Ion exchange: exchange the filtrate obtained by hydrolysis with cation resin for 5 times to further remove base metal impurities to obtain a pure platinum group metal solution; the resin is a strong acid cation exchange resin with a flow rate of 200ml / min until the base metal The metal content is less than 0.0001g / L.

[0040] (3) Concentration: Concentrate the solution composed of iridium, platinum, palladium, rhodiu...

Embodiment 3

[0045] A method for separating iridium from base metals and other platinum group metals, comprising the steps of:

[0046] (1) Hydrolysis of impurity removal: Slowly add 400 g of NaOH to 2000 ml of iridium solution containing a small amount of platinum, palladium, rhodium, ruthenium and base metal impurities such as Fe, Pb, Sn, Mg, Zn and stir at a stirring speed of 65 r / min , stirred for 25 minutes, adjusted the pH value of the solution to 10.5, filtered with a funnel and a suction filter bottle, and hydrolyzed the base metal to form a hydroxide precipitate to be removed;

[0047] (2) Ion exchange: exchange the filtrate obtained by hydrolysis with cation resin for 4 times to further remove base metal impurities to obtain a pure platinum group metal solution; the resin is a strong acid cation exchange resin with a flow rate of 200ml / min until the base metal The metal content is less than 0.0001g / L.

[0048] (3) Concentration: Concentrate the solution composed of iridium, plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com