Preparation method of elemental copper-clad multi-wall carbon nanotube/aluminum matrix composite semi-solid billet

A technology for multi-walled carbon nanotubes and aluminum-based composite materials, which is applied in the field of material preparation, can solve the problems of lack of carbon nanotube-reinforced aluminum-based composite materials preparation and forming technology, unfavorable performance improvement of composite materials, and easy agglomeration of carbon nanotubes. , to achieve the effect of reducing the probability of agglomeration, low risk factor and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

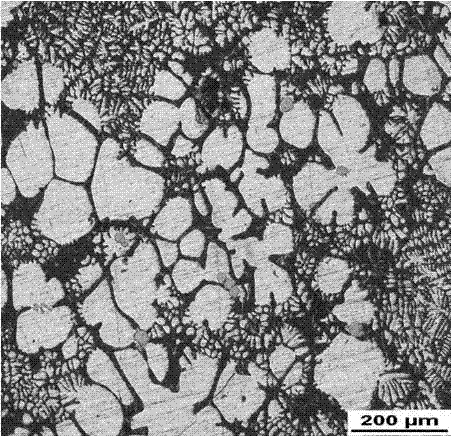

Image

Examples

Embodiment 1

[0033] Multi-walled carbon nanotubes were ultrasonically pre-dispersed in pure nitric acid solution for 8 hours at 60°C. After cooling to room temperature, they were washed with deionized water, centrifuged until neutral, and then dried in a vacuum oven for later use. Copper nitrate and the above-mentioned dried multi-walled carbon nanotubes were used as raw materials, and were added into pure ethanol for ultrasonication for 40 minutes; wherein the molar ratio of multi-walled carbon nanotubes, copper nitrate and ethanol was 1:0.4:127, and the suspension of multi-walled carbon nanotubes was obtained. liquid; the suspension is introduced into the hydrothermal reaction kettle, wherein the volume of the suspension accounts for 25% of the volume of the reaction kettle. Then put it into the reaction furnace to heat, raise the temperature to 200°C at 3°C / min, keep it for 2 hours, then raise the temperature to 300°C at 3°C / min, and keep it for 8 hours; seal and cool to room temperature...

Embodiment 2

[0036] Multi-walled carbon nanotubes were ultrasonically pre-dispersed in pure nitric acid solution for 8 hours at 60°C. After cooling to room temperature, they were washed with deionized water, centrifuged until neutral, and then dried in a vacuum oven for later use. Copper nitrate and the above-mentioned dried multi-walled carbon nanotubes were used as raw materials, and were added into pure ethanol for ultrasonication for 50 minutes; wherein the molar ratio of carbon nanotubes, copper nitrate and ethanol was 1:0.6:127 to obtain a multi-walled carbon nanotube suspension; The suspension is introduced into a hydrothermal reaction kettle, wherein the volume of the suspension accounts for 25% of the volume of the reaction kettle. Then put it into the reaction furnace to heat, raise the temperature to 200°C at 5°C / min, keep it warm for 1h, then raise the temperature to 300°C at 3°C / min, keep it warm for 8h; seal and cool to room temperature, filter and dry at low temperature, then...

Embodiment 3

[0039] Multi-walled carbon nanotubes were ultrasonically pre-dispersed in pure nitric acid solution for 8 hours at 60°C. After cooling to room temperature, they were washed with deionized water, centrifuged until neutral, and then dried in a vacuum oven for later use. Copper nitrate and the above-mentioned dried multi-walled carbon nanotubes were used as raw materials, and were added into pure ethanol for ultrasonication for 60 minutes; wherein the molar ratio of multi-walled carbon nanotubes, copper nitrate and ethanol was 1:0.8:127, and the suspension of multi-walled carbon nanotubes was obtained. liquid; the suspension is introduced into the hydrothermal reaction kettle, wherein the volume of the suspension accounts for 25% of the volume of the reaction kettle. Then put it into the reaction furnace to heat, raise the temperature to 200°C at 3°C / min, keep it for 1h, then raise the temperature to 300°C at 3°C / min, keep it for 10h; seal and cool to room temperature, filter and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com