Pressure resistant built-up water storing module

A combined, pressure-bearing column technology, applied in general water supply conservation, water supply equipment, waterway systems, etc., can solve the problems of poor pressure bearing capacity, easy to be damaged by pressure, short service life, etc., to achieve high pressure bearing capacity, open The effect of low mold cost and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

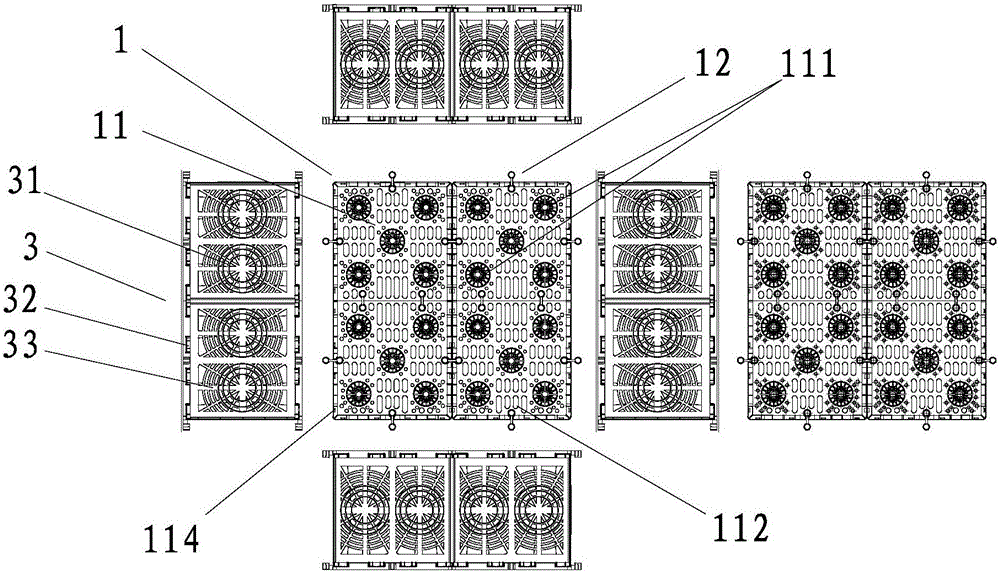

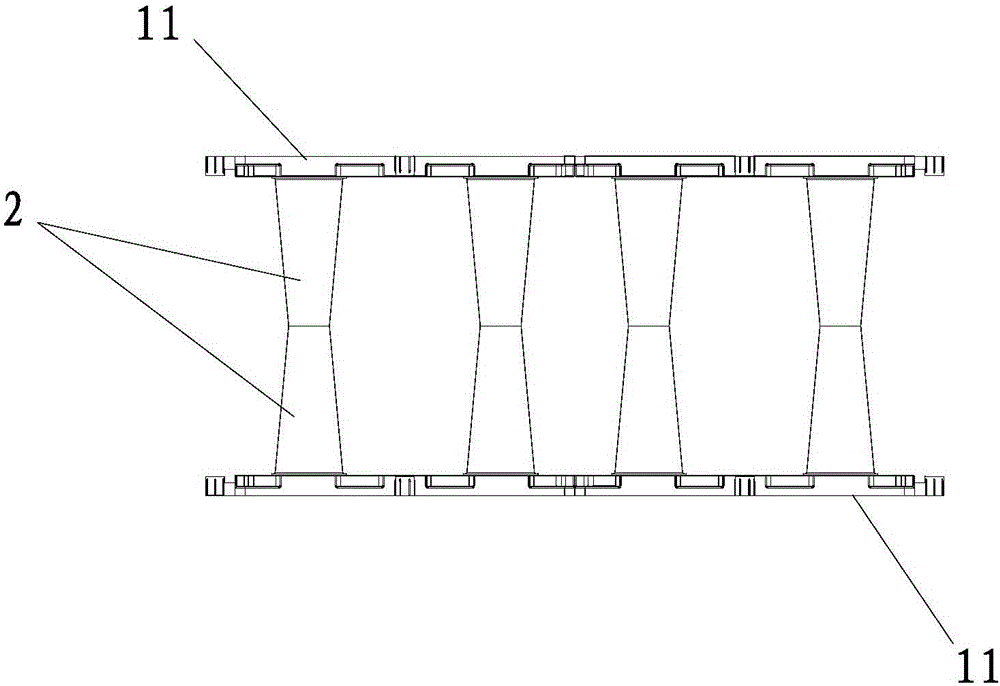

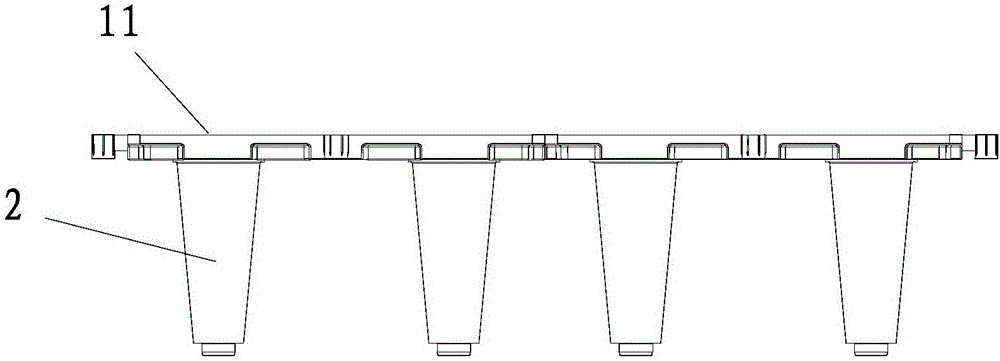

[0037] Such as figure 1 , Figure 4 , Figure 5 , Figure 6 Shown: a pressure-resistant combined water storage module, including two square pressure-bearing plates 1, sixteen pressure-bearing columns 2 and four rectangular side plates 3.

[0038]The two pressure bearing plates and the four side plates form a cube, and the two pressure bearing plates form the top surface and the bottom surface of the cube respectively. Each of the pressure bearing plates is spliced by four square splicing plates 11, and the splicing plate is provided with a main water hole 111 and an auxiliary water hole 112, and the four sides of the splicing plate are provided with splicing circles. The groove 113 and the hook-shaped buckle 114 are used for splicing between adjacent splicing plates through the splicing buckle 12 arranged in the splicing circular groove. Wherein, the four corners and the center of each splicing plate are respectively provided with main water holes, and the main water hol...

Embodiment 2

[0043] The difference between this embodiment and the embodiment is that, as Figure 9 As shown, the outer wall of the pressure-bearing column in Embodiment 2 is provided with a water hole 23 .

Embodiment 3

[0045] In this embodiment, the material of the water storage module is a compression-resistant PVC-based composite plastic, and the compression-resistant PVC-based composite plastic is prepared by mixing the following raw materials in parts by mass: 45 parts of PVC, 15 parts of MBS, modified 15 parts of EVA, 4 parts of wood fiber, 2 parts of nano-silica, 10 parts of calcium carbonate, 5 parts of talcum powder, and 4 parts of glass beads.

[0046] Wherein, the preparation method of the modified EVA is: heating the graphene oxide aqueous solution with a concentration of 22wt% to 50°C, and then stirring, during the stirring, adding the water-soluble polyamic acid solution dropwise to the graphene oxide aqueous solution to obtain a sol The concentration of the water-soluble polyamic acid solution is 5wt%, and the amount added dropwise is 5.5 times the volume of the graphene oxide aqueous solution; the sol is left at room temperature for 6h, and the unreacted substances in the sol a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com