A kind of etching method of tantalum nitride tan film

A tantalum nitride and thin film technology, which is applied in the etching field of tantalum nitride and TaN thin film, can solve the problems of reducing product yield, affecting the compatibility of etching process, aggravating damage, etc., and achieving the effect of uniform etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object and technical effect of the present invention more clear and complete, the specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

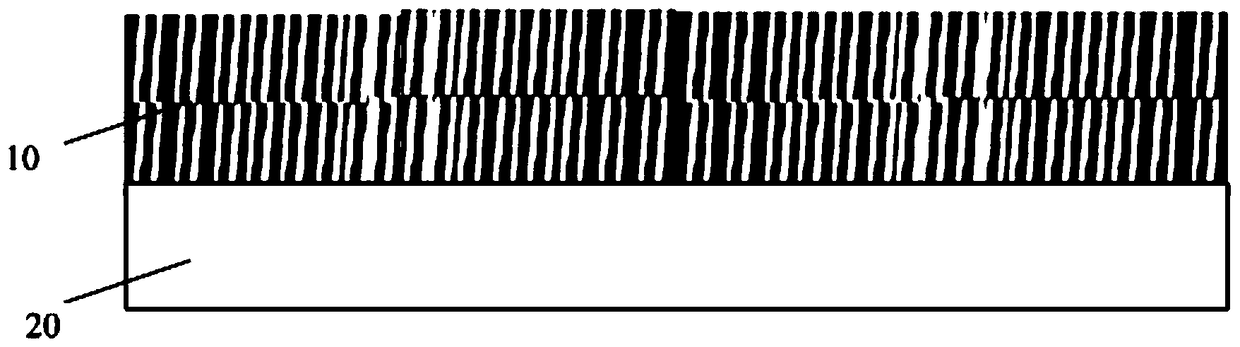

[0028] figure 1 is a schematic diagram of the structure of a TaN thin film with a crystalline structure containing columnar crystals. from the figure 1 It can be seen that the internal microstructure of the TaN thin film 10 is not uniform. Its inhomogeneous microstructure leads to different etching rates in different regions of the TaN film. And the etch rate at the grain boundary or crystal defect is too fast. This leads to over-etching at grain boundaries or at crystallographic defects when other regions are fully etched. The occurrence of over-etching and the enhancement of ion bombardment at the defect will transfer the defect of the TaN film to the film structure 20 below it, forming a defect that will affect the performance of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com