Preparing method for vanadium based composite titanium dioxide catalyst used in ammonium bisulfate decomposition during De-NOxDenitration

A technology of composite titanium dioxide and catalyst, which is applied in the field of denitrification catalyst, can solve the problems of corroding the air preheater, high risk of flushing, blocking the pores of the air preheater, etc., and achieves simple process, strong operability, and reduced decomposition The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a vanadium-based composite titanium dioxide catalyst used for the decomposition of ammonium bisulfate in the process of industrial flue gas denitrification comprises the following steps in sequence:

[0028] (1) Add 250g of metatitanic acid into 1L of water, stir, heat to 80°C, adjust its pH value to 5 with ammonia water, filter, wash, dry, and then roast at 400°C to obtain the corresponding composite titanium dioxide;

[0029] (2) get the titanium dioxide prepared in 99g (1), add 1.2g ammonium metavanadate;

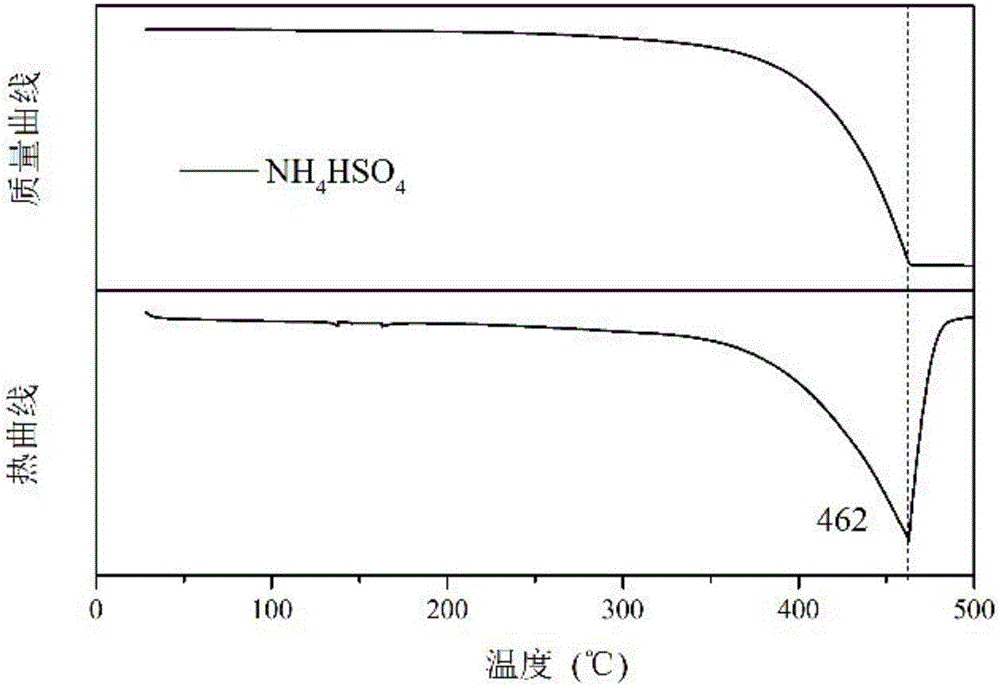

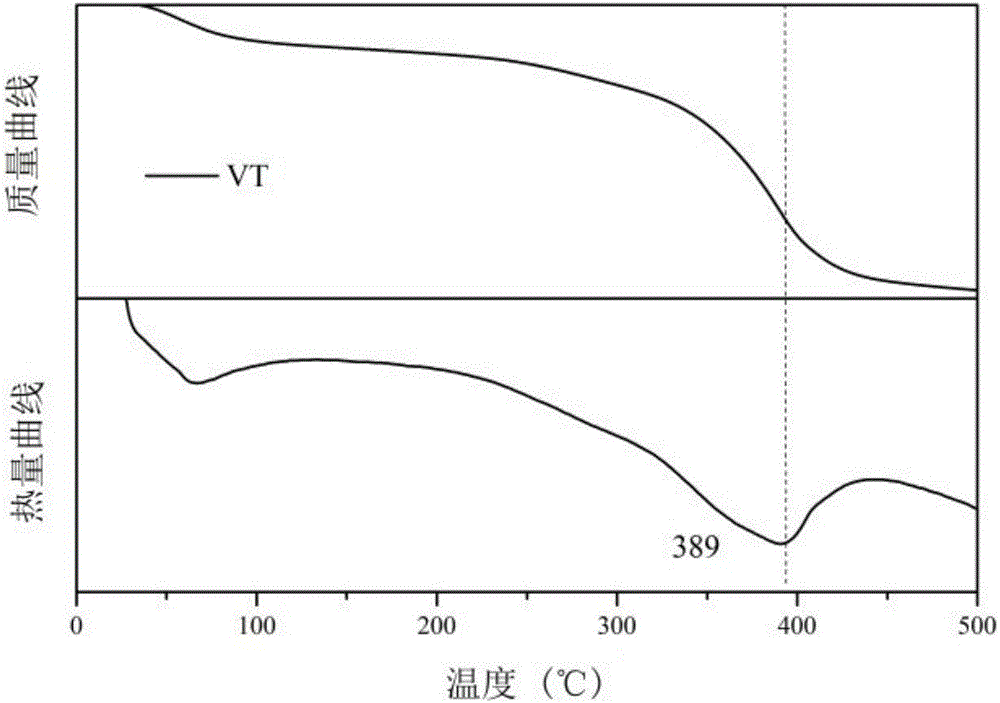

[0030] (3) The mixture obtained in (2) was added to 0.5 L of water, heated to 70°C, stirred, evaporated to dryness, and calcined at 500°C to obtain the corresponding vanadium-based titanium dioxide catalyst. figure 2 The thermogravimetric curve of the prepared vanadium-based titanium dioxide catalyst loaded with 10% by mass of ammonium bisulfate. It can be seen that the fastest decomposition temperature of this vanadium-based titanium dio...

Embodiment 2

[0032] A preparation method of a vanadium-based composite titanium dioxide catalyst used for the decomposition of ammonium bisulfate in the process of industrial flue gas denitrification comprises the following steps in sequence:

[0033] (1) Add 300g of metatitanic acid to 1L of water, then add 9.8g of antimony acetate, stir, heat to 80°C, adjust its pH value to 6.0 with ammonia water, filter, wash, dry, and then roast at 500°C to obtain the corresponding antimony doped titanium dioxide;

[0034] (2) Get 98g of the antimony-doped titanium dioxide prepared in (1), add 2.4g of ammonium metavanadate, and then add 0.7L of water to form a certain mixed solution;

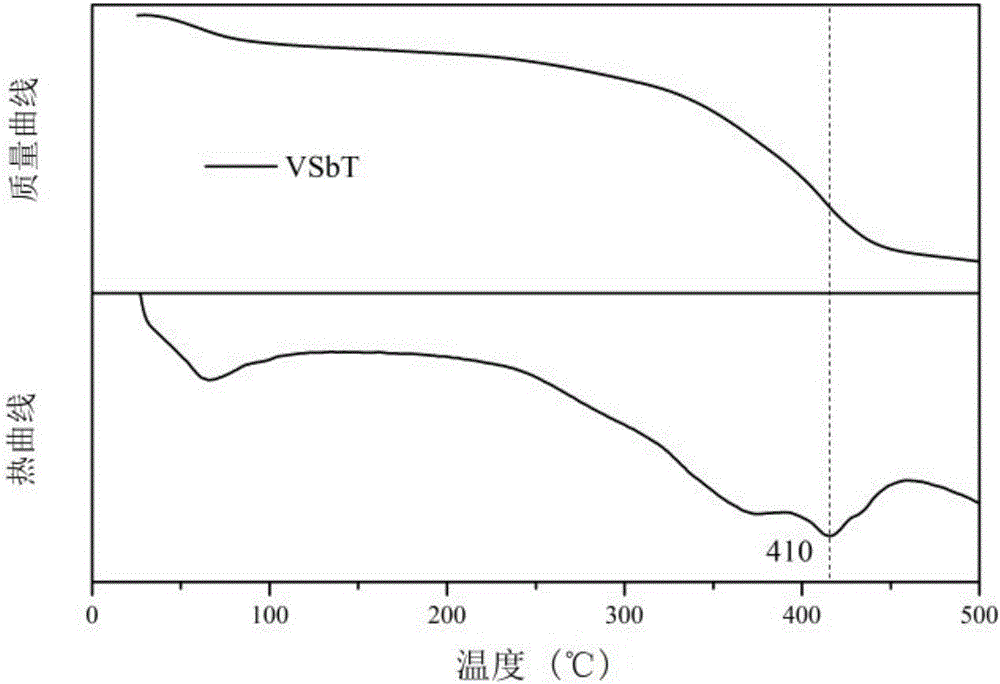

[0035] (3) Heating the mixed liquid obtained in (2) to 75° C., stirring, evaporating to dryness, and calcining at 550° C. to obtain the corresponding vanadium-based antimony-doped titanium dioxide catalyst. image 3 The thermogravimetric curve of the prepared vanadium-based antimony-doped titanium dioxide catalyst loade...

Embodiment 3

[0037] A preparation method of a vanadium-based composite titanium dioxide catalyst used for the decomposition of ammonium bisulfate in the process of industrial flue gas denitrification comprises the following steps in sequence:

[0038] (1) Add 400g of metatitanic acid to 1L of water, then add 17g of barium sulfate, stir, heat to 80°C, adjust its pH value to 6.0 with ammonia water, filter, wash, dry, and then roast at 600°C to obtain the corresponding Barium sulfate doped titanium dioxide;

[0039] (2) get the barium sulfate doped titanium dioxide prepared in 97g (1), 3.6g ammonium metavanadate, then add 1.0L water;

[0040] (3) Heating the mixed solution obtained in (2) to 80° C., stirring, evaporating to dryness, and calcining at 600° C. to obtain the corresponding vanadium-based barium sulfate-doped titanium dioxide catalyst. Figure 4 The thermogravimetric curve of the prepared vanadium-based barium-doped titanium dioxide catalyst loaded with 10% by mass of ammonium bis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com