A liquid forming device for light alloy

A technology of liquid forming and light alloy, which is applied in casting forming equipment, molds, cores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

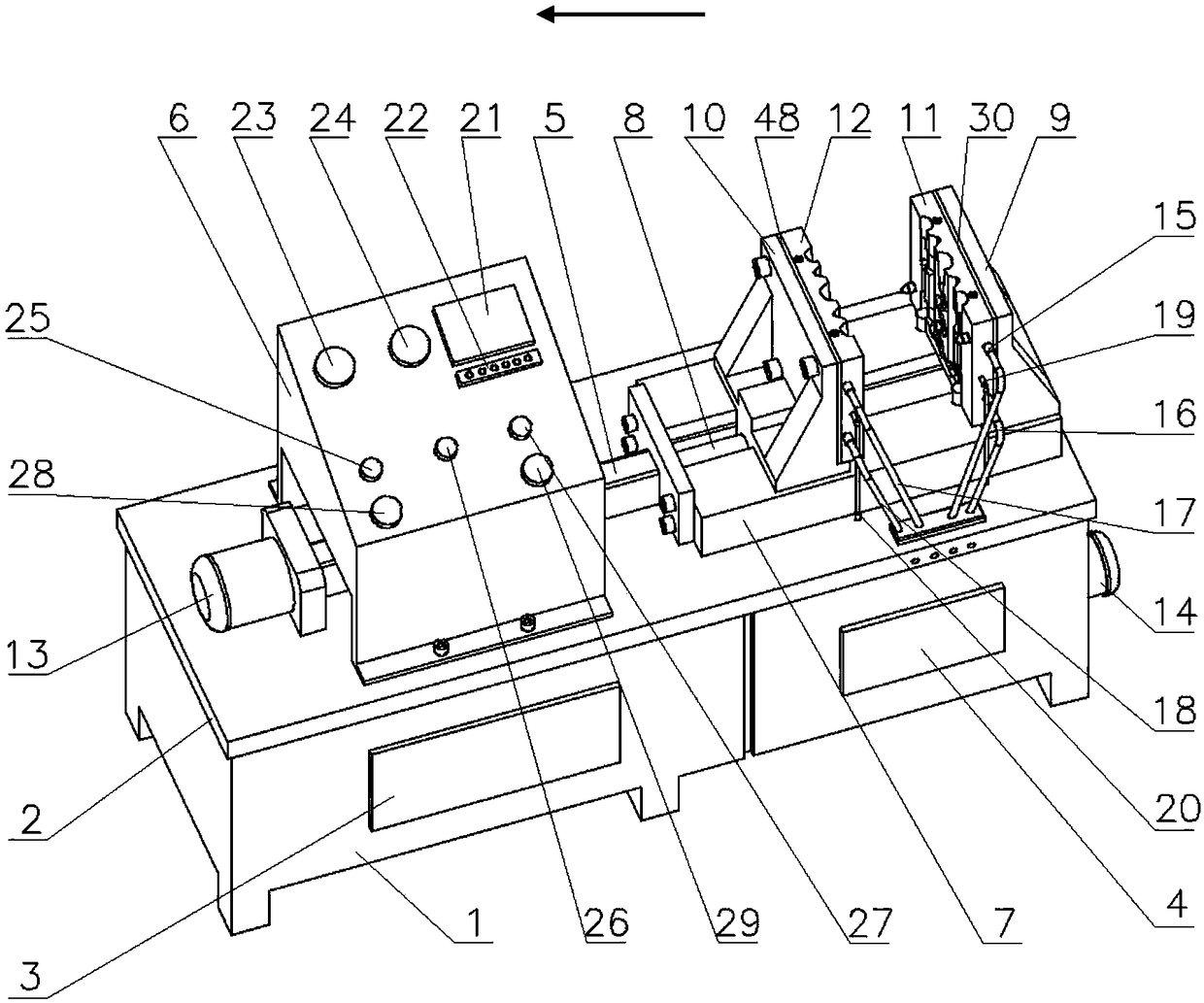

[0020] figure 1 As shown, it is the overall structure diagram of the light alloy liquid forming device, the position and connection relationship of each part must be correct, and the installation should be firm;

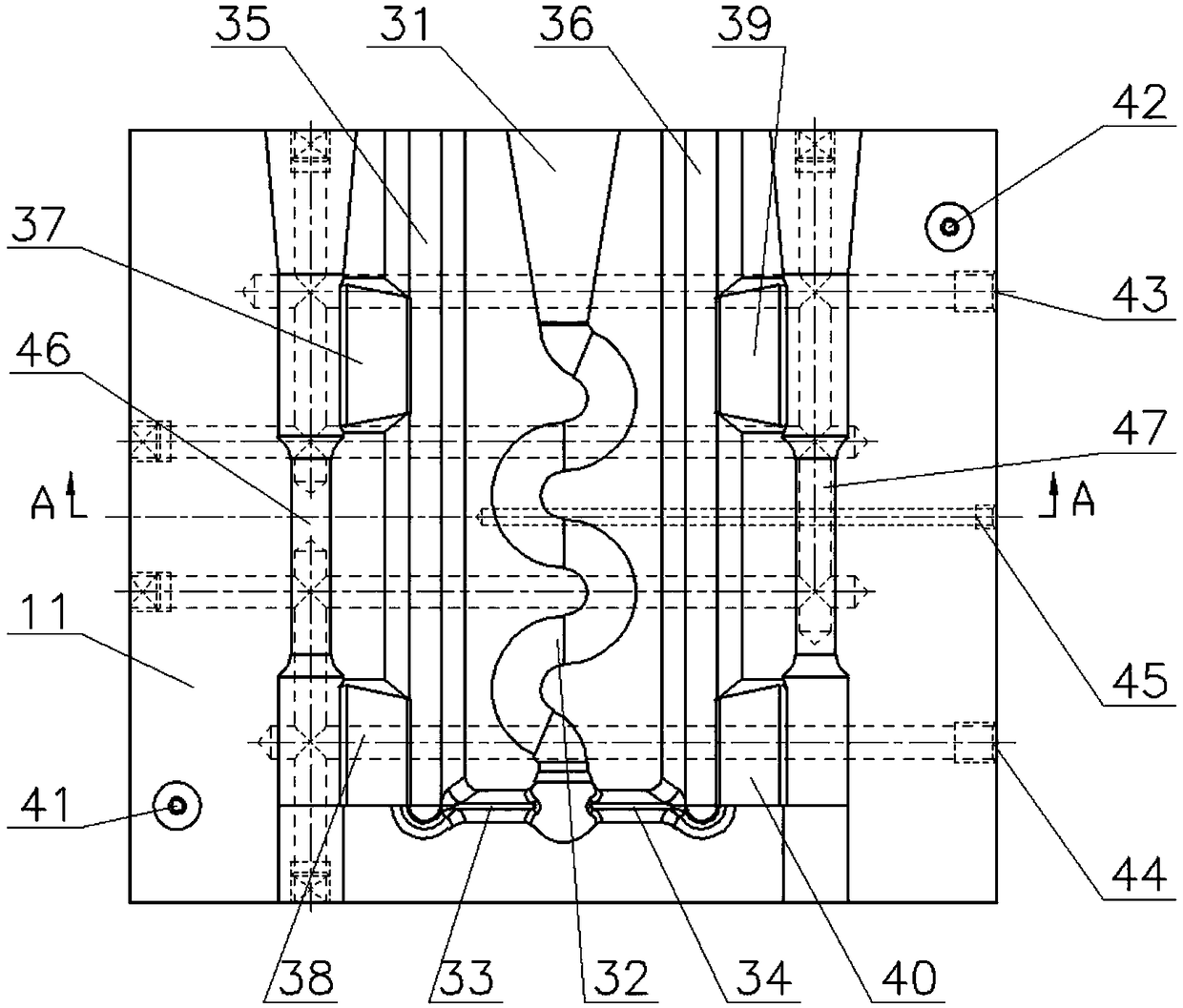

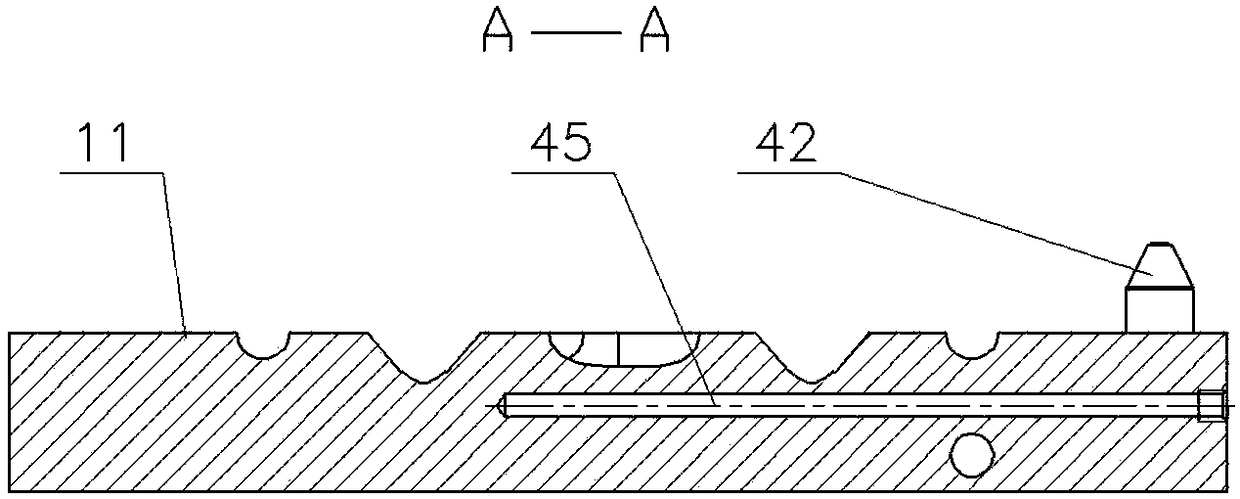

[0021] The liquid forming device of light alloy is horizontal, the bottom is machine base 1, the upper part of machine base 1 is workbench 2, and the left part of workbench 2 is provided with push-pull rod motor 13, guide rail 5, and guide rail 5 is provided with push Tie bar 8; mold seat 7 is provided on the right part of workbench 2, fixed template 9 and movable template 10 are arranged on mold seat 7, fixed template 9 is fixed on the right side of mold seat 7, movable template 10 is fixed with push-pull rod 8 Connect; install fixed mold insulation board 30, fixed mold 11 on fixed template 9, install movable mold insulation board 48, movable mold 12 on movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com