A wear plate for hook tail frame support plate

A wear plate and coupler frame technology, which is applied in the direction of adhesive additives, layered products, metal layered products, etc., can solve problems such as damage to the support plate body of the coupler frame and difficulty in replacing wear plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

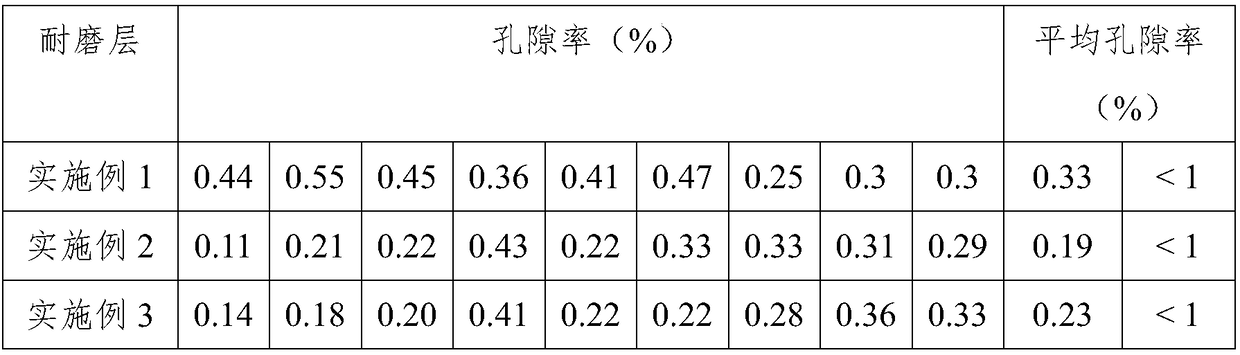

Embodiment 1

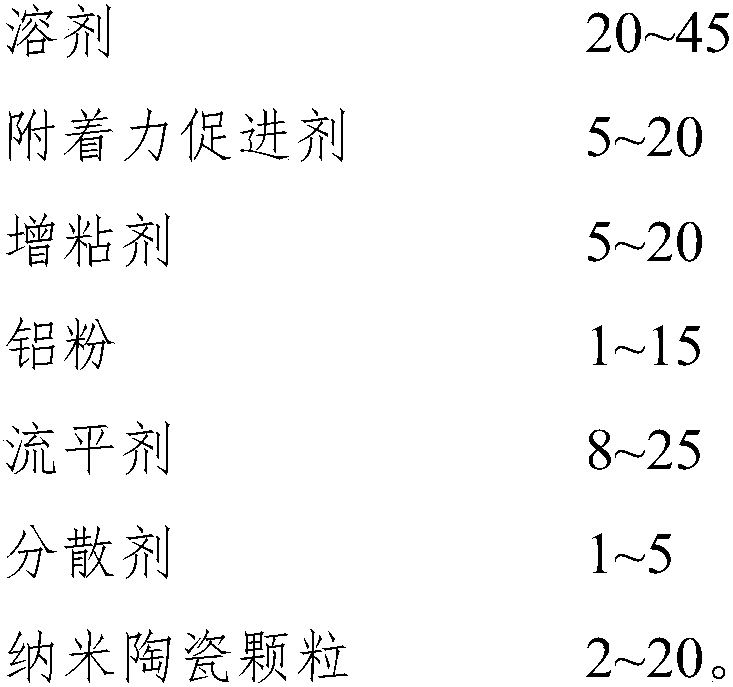

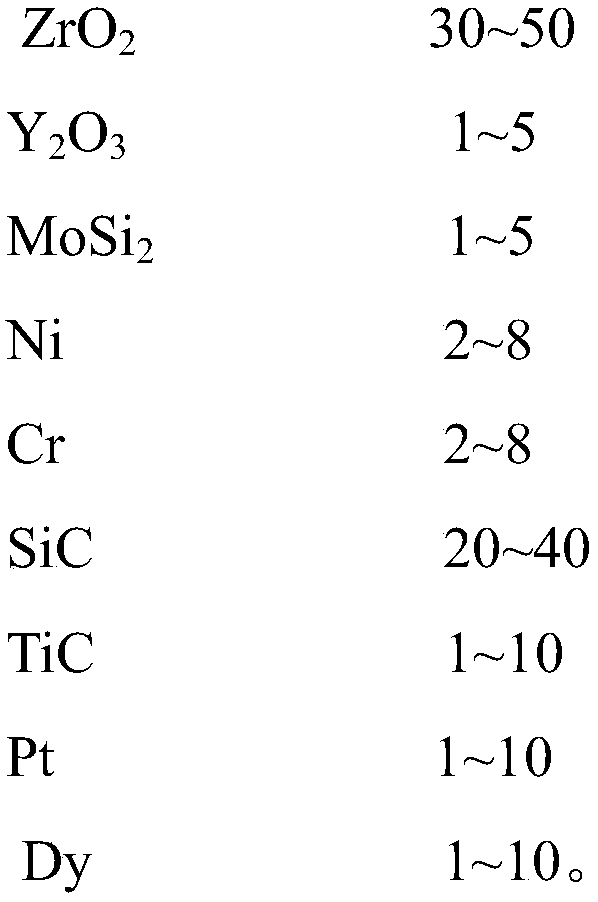

[0026] The wear plate of the hook tail frame supporting plate of the present invention selects polytetrafluoroethylene engineering plastics as the substrate material to prepare the wearing plate of the hook tail frame supporting plate, and prepares a rough surface on the surface of the base plate through a shot blasting process, which is convenient for preparing a bonding layer and increases Adhesive properties of the adhesive layer to the substrate.

[0027] The bonding layer is composed of the following components by mass: 44 parts of methyl propylene glycol solvent, 16 parts of a mixture of epoxy resin and polyurethane resin as an adhesion promoter, wherein the mass ratio of epoxy resin and polyurethane resin is 1:3 ; 8 parts of m-dimethylstyrene tackifier, 2 parts of aluminum powder, 10 parts of pottery clay, calcium carbonate, styrene-butadiene rubber, tetrasodium pyrophosphate and fluorine-containing surfactant mixture as leveling agent, wherein pottery clay, carbonic aci...

Embodiment 2

[0031] The wear plate of the hook tail frame supporting plate of the present invention selects polycarbonate engineering plastics as the substrate material to prepare the wearing plate of the hook tail frame supporting plate, and prepares a rough surface on the surface of the base plate through a shot blasting process, which is convenient for preparing an adhesive layer and increases the adhesion. Bonding properties of the junction layer to the substrate.

[0032] The bonding layer is made up of the following components by mass: 38 parts of acetone solvent, 16 parts of a mixture of epoxy resin and polyurethane resin as an adhesion promoter, wherein the mass ratio of epoxy resin and polyurethane resin is 2:2; 8 1 part of p-methylstyrene tackifier, 8 parts of aluminum powder, 13 parts of clay, calcium carbonate, styrene-butadiene rubber, tetrasodium pyrophosphate and fluorine-containing surfactant as a leveling agent, of which clay, calcium carbonate, butadiene The mass ratio of...

Embodiment 3

[0036] The wear plate of the hook tail frame supporting plate of the present invention selects polyamide engineering plastics as the substrate material to prepare the wearing plate of the hook tail frame supporting plate, and prepares a rough surface on the surface of the base plate through a shot blasting process, which facilitates the preparation of an adhesive layer and increases the adhesion Layer-to-substrate adhesion properties.

[0037] The bonding layer is composed of the following components by mass: 40 parts of pentaerythritol solvent, 11 parts of a mixture of epoxy resin and polyurethane resin as an adhesion promoter, wherein the mass ratio of epoxy resin and polyurethane resin is 3:4; 5 1 part of o-methyl styrene tackifier, 14 parts of aluminum powder, 15 parts of a mixture of clay, calcium carbonate, styrene-butadiene rubber, tetrasodium pyrophosphate and fluorine-containing surfactant as a leveling agent, of which clay, calcium carbonate, butadiene The mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com