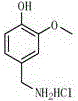

Preparation method for vanillylamine hydrochloride

A technology of vanillin amine hydrochloride and composite catalyst, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of amino hydroxyl compounds, etc., can solve the problems of low yield, high risk, high investment, etc. High efficiency, low cost, good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

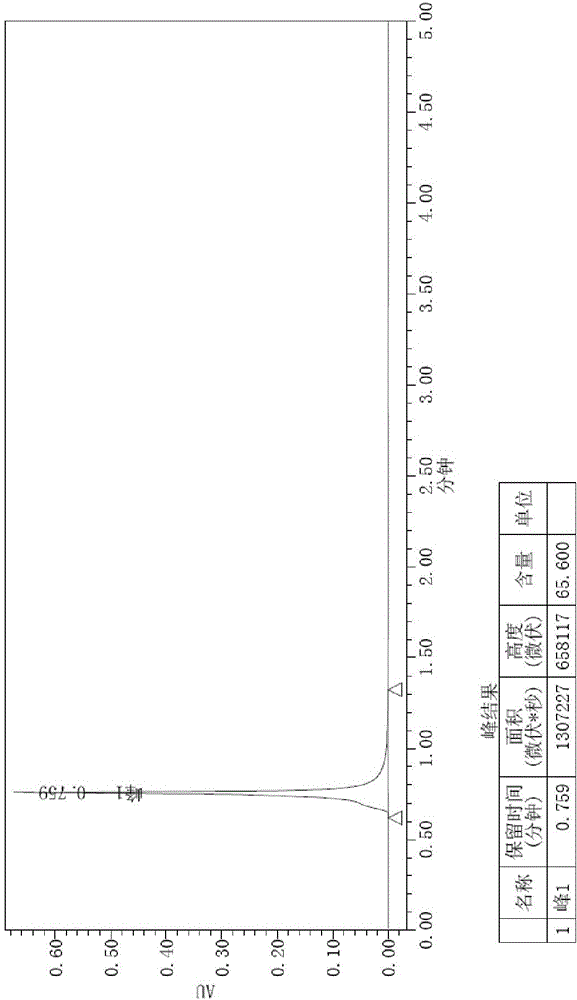

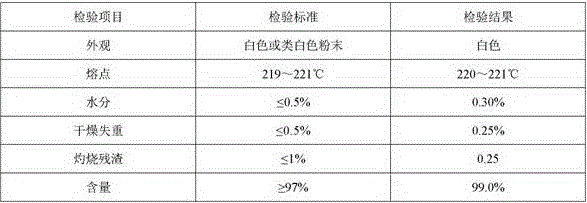

Image

Examples

Embodiment 1

[0036] The preparation method of vanillin amine hydrochloride of the present invention, the detailed steps of this preparation method are as follows:

[0037] a. Using 3-methoxy-4-hydroxybenzaldehyde oxime as raw material and ethanol as solvent; first, add 133.6g (0.80mol) of 3-methoxy-4-hydroxybenzaldehyde oxime into a device equipped with a stirrer and a thermometer Then add 1400mL of ethanol and 13.0g of aluminum-zinc-nickel composite catalyst into a 2L three-necked flask, pass hydrogen under normal pressure for protection, heat up to 40°C, and react at this temperature for 8h;

[0038] b. Filtrate after the reaction (the obtained filter residue is unreacted composite catalyst, which is recovered and recycled), add 70mL of hydrochloric acid with a mass percentage concentration of 30% to the obtained filtrate, adjust the pH value of the filtrate to 1, and precipitate white crystals , filtered the separated white crystals, and obtained 136.8 g of vanillin amine hydrochloride ...

Embodiment 2

[0046] The preparation method of vanillin amine hydrochloride of the present invention, the detailed steps of this preparation method are as follows:

[0047]a. Using 3-methoxy-4-hydroxybenzaldehyde oxime as raw material and ethanol as solvent; first, add 133.6g (0.80mol) of 3-methoxy-4-hydroxybenzaldehyde oxime into a device equipped with a stirrer and a thermometer In a 2L three-necked flask, add 1400mL ethanol and 13.0g aluminum-zinc-nickel composite catalyst, pass hydrogen gas under normal pressure for protection, heat up to 50°C, and react at this temperature for 7h;

[0048] b. Filtrate after the reaction (the obtained filter residue is unreacted composite catalyst, which is recovered and recycled), add 70mL of hydrochloric acid with a mass percentage concentration of 30% to the obtained filtrate, adjust the pH value of the filtrate to 1, and precipitate white crystals , filtered the precipitated white crystals, and obtained 134.4 g of vanillinamine hydrochloride finishe...

Embodiment 3

[0056] The preparation method of vanillin amine hydrochloride of the present invention, the detailed steps of this preparation method are as follows:

[0057] a. Using 3-methoxy-4-hydroxybenzaldehyde oxime as raw material and ethanol as solvent; first, add 133.6g (0.80mol) of 3-methoxy-4-hydroxybenzaldehyde oxime into a device equipped with a stirrer and a thermometer In a 2L three-neck flask, add 1500mL ethanol and 20.0g aluminum-zinc-nickel composite catalyst, pass hydrogen gas under normal pressure for protection, heat up to 60°C, and react at this temperature for 6h;

[0058] b. Filtrate after the reaction (the obtained filter residue is unreacted composite catalyst, which is recovered and recycled), add 70mL of hydrochloric acid with a mass percentage concentration of 30% to the obtained filtrate, adjust the pH value of the filtrate to 1, and precipitate white crystals , filtered the separated white crystals, and obtained 132.1 g of vanillin amine hydrochloride finished p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com