Preparation method of group A/C meningococcal polysaccharide

A technology of meningococcal and capsular polysaccharides, applied in the field of biomedicine, can solve the problems of phenol environmental hazards, water and air pollution, and achieve the effects of avoiding large-scale use, avoiding environmental damage, and preventing phenol from damaging the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

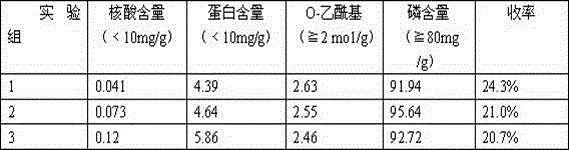

[0023] Preparation of Group A Meningococcal Polysaccharide

[0024] Open a working seed batch of group A meningococcus, and inoculate it into two test tubes of meningococcal semi-comprehensive medium at a temperature of 35-37°C and cultivate for 16-24 hours, which is the first-generation strain. Each first-generation strain is propagated on 2 bottles of meningococcal semi-comprehensive medium at a temperature of 35-37°C for 16-24 hours, which is the second-generation strain. Inoculate each bottle of second-generation strains on 6 bottles of meningococcal semi-comprehensive medium at a temperature of 35-37°C for 16-24 hours to form third-generation strains. The three generations of bacteria were collected in 500ml of physiological saline solution and mixed well, and then inoculated in a 50L seed tank at a temperature of 35-37°C and a culture time of 4 hours. Then, 50L seed tank culture was inoculated into 500L fermenter for culture, the temperature was 35~37℃, and after 8 hours o...

Embodiment 2

[0029] Preparation of Group C Meningococcal Polysaccharide

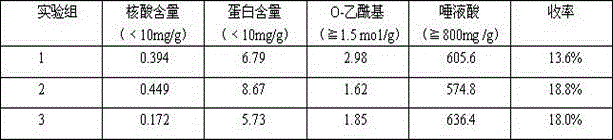

[0030] Open 1 working seed batch of group C meningococcus and inoculate it into 2 test tubes of meningococcal semi-comprehensive medium at a temperature of 35~37℃ and cultivate for 16~24 hours, which is the first generation of bacteria. Each first-generation strain is propagated on 2 bottles of meningococcal semi-comprehensive medium at a temperature of 35-37°C for 16-24 hours, which is the second-generation strain. Inoculate each bottle of second-generation strains on 6 bottles of meningococcal semi-comprehensive medium at a temperature of 35-37°C for 16-24 hours to form third-generation strains. The three generations of bacteria were collected in 500ml of physiological saline solution and mixed well, and then inoculated in a 50L seed tank at a temperature of 35-37°C and a culture time of 4 hours. Then, 50L seed tank culture was inoculated into 500L fermenter for culture, the temperature was 35~37℃, and after 8 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com