Late transition metal catalyst for ethylene oligomerization and preparation method thereof

A technology of transition metal and ethylene oligomerization, applied in the directions of physical/chemical process catalysts, catalysts, carbon compound catalysts, etc., can solve the problems of long synthesis steps, difficult industrial production, low total yield, etc., and achieves a simple and easy preparation method. Industrial production, the effect of high catalytic ethylene oligomerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

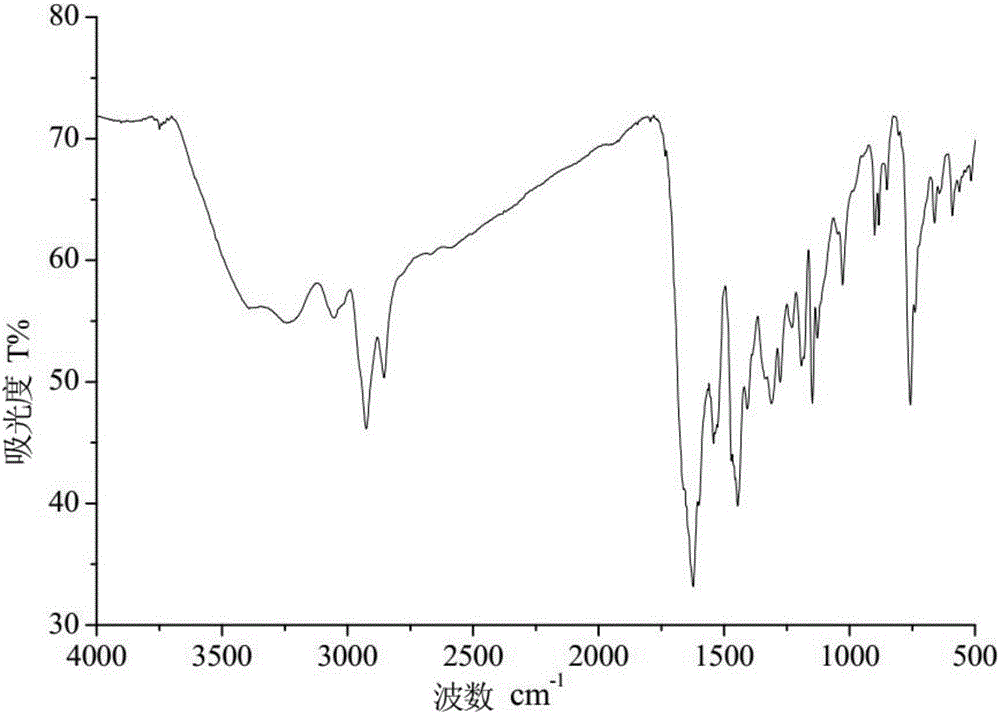

Embodiment 1

[0048] This embodiment provides a late transition metal catalyst for ethylene oligomerization, its structural formula is as shown in formula (1-1):

[0049]

[0050] This embodiment also provides a preparation method for the late transition metal catalyst for ethylene oligomerization described in formula (1-1), which comprises the following steps:

[0051] Step 1, under a nitrogen atmosphere, add 3g of anhydrous sodium sulfate, cyclohexylamine as a solution of ethanol (20mL) of 1.0G hyperbranched macromolecules (3.27g, 0.01mol) and salicylaldehyde (3.66 g, 0.03mol) of ethanol (20mL), stirred at room temperature for 30min, then warmed up to 78°C, reacted under ethanol reflux for 12h, and filtered to remove anhydrous sodium sulfate to obtain hyperbranched water with cyclohexylamine as the nucleus. Mixed solution of salicylaldimine ligand;

[0052] Step 2, under nitrogen atmosphere, NiCl 2 ·6H 2 The ethanol (20mL) solution of O (2.38g, 0.01mol) is slowly dripped into the hy...

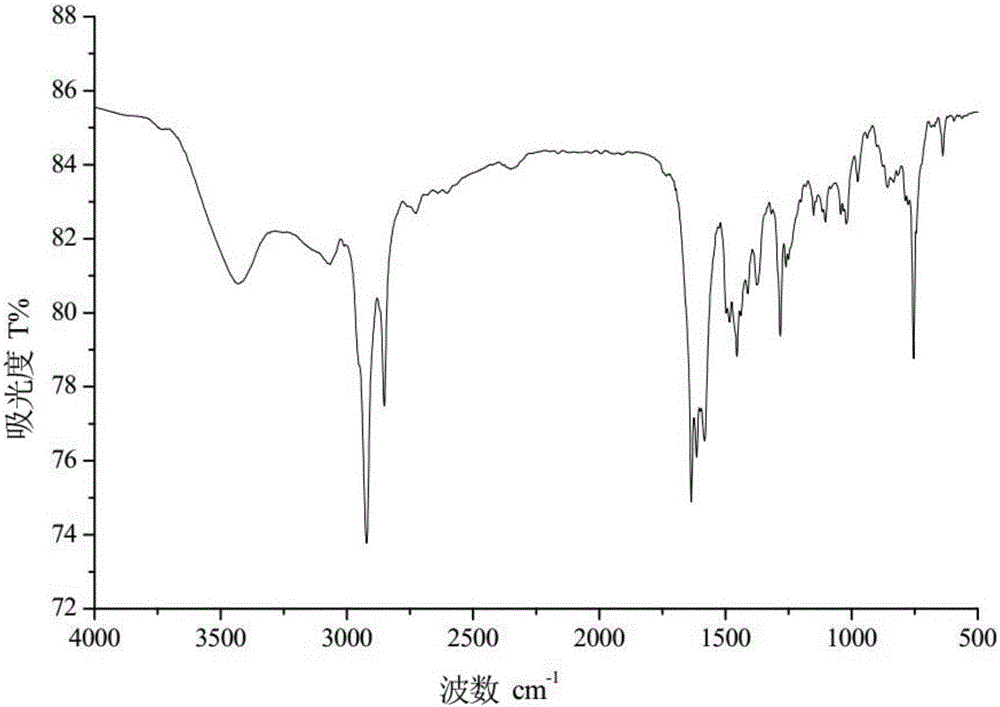

Embodiment 2

[0058] This embodiment provides a late transition metal catalyst for ethylene oligomerization, the structural formula of which is shown in formula (2-1):

[0059]

[0060] This embodiment also provides a preparation method for the late transition metal catalyst for ethylene oligomerization described in formula (2-1), which comprises the following steps:

[0061] Step 1, under a nitrogen atmosphere, add 3g of anhydrous sodium sulfate, linear tetradecylamine as a solution of 1.0G hyperbranched macromolecules (4.30g, 0.01mol) in ethanol (20mL) and salicylaldehyde in a three-necked flask (6.11g, 0.05mol) in ethanol (20mL), stirred at room temperature for 30min, then heated to 80°C, reacted for 24h under ethanol reflux, and filtered to remove anhydrous sodium sulfate to obtain linear tetradecylamine as the nucleus The hyperbranched salicylaldimine ligand mixed solution;

[0062] Step 2, under nitrogen atmosphere, NiCl 2 ·6H 2 The ethanol (40mL) solution of O (4.76g, 0.02mol) ...

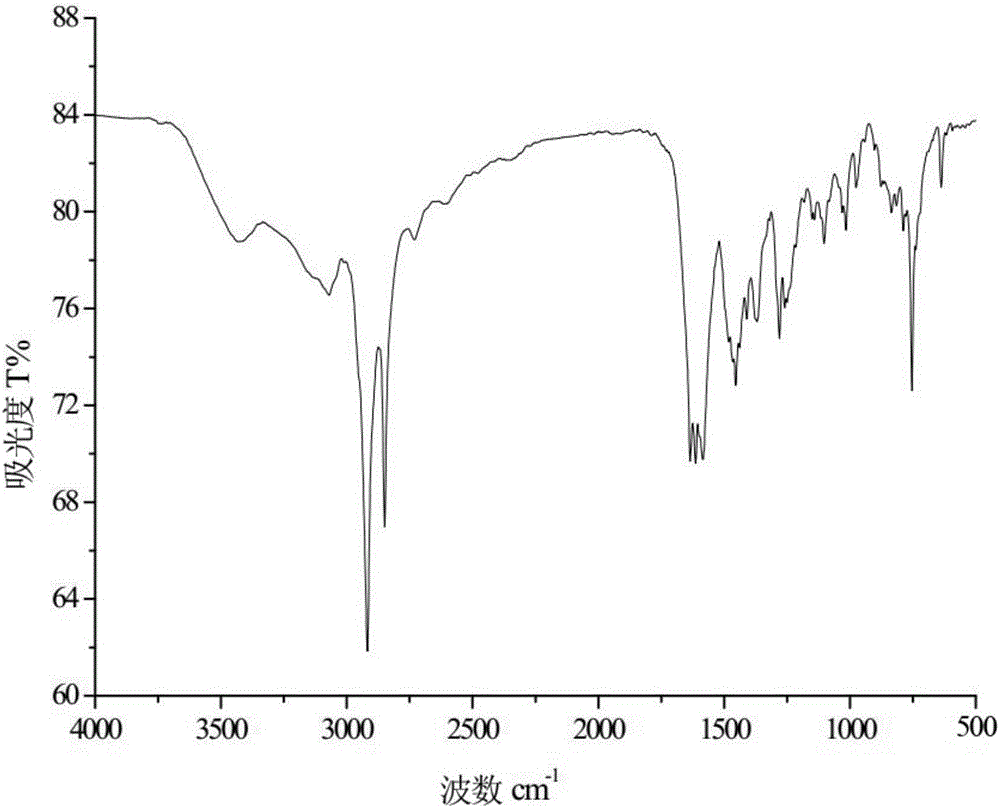

Embodiment 3

[0068] This embodiment provides a late transition metal catalyst for ethylene oligomerization, the structural formula of which is shown in formula (3-1):

[0069]

[0070] This embodiment also provides a preparation method for the late transition metal catalyst for ethylene oligomerization described in formula (3-1), which comprises the following steps:

[0071] Step 1, under a nitrogen atmosphere, add 3g of anhydrous sodium sulfate, straight-chain octadecylamine as a solution of 1.0G hyperbranched macromolecules (4.86g, 0.01mol) in ethanol (20mL) and salicylaldehyde in a three-necked flask (3.05g, 0.025mol) in ethanol (20mL), stirred at room temperature for 30min, then heated to 70°C, reacted under ethanol reflux for 18h, and filtered to remove anhydrous sodium sulfate to obtain linear octadecylamine as the nucleus. Hyperbranched salicylaldimine ligand mixed solution;

[0072] Step 2, under nitrogen atmosphere, the CoCl 2 ·6H 2 O (2.38g, 0.01mol) ethanol (20mL) solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com