Preparation method of abrasion-resistant coating of stainless steel base material

A technology for stainless steel and substrates, applied in metal material coating process, coating, molten plating, etc., can solve the problems of graphene agglomeration, long time consumption, complex coating solution preparation process and coating process, etc., to achieve The preparation method is simple, the price is cheap, and the effect of coating film thickness is controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: The preparation method of the anti-wear coating is as follows: immerse the stainless steel substrate in an acetone solution and sonicate for 1 hour; 98% concentrated sulfuric acid and 30% hydrogen peroxide solution are made into an oxidizing agent at a volume ratio of 3:1 to the substrate Carry out oxidation, wash and dry after reacting for 90 minutes; make a solution according to the ratio of aminosilane coupling agent (about 1% by volume fraction), acetone (about 80% by volume fraction), and water (about 19% by volume fraction), after fully stirring Immerse the stainless steel substrate in it and let it stand for 1h. Then soak it in 50ml of 0.4mg / ml graphene oxide solution. The solution casting process is kept at a temperature of 110°C. After the graphene oxide is coated on the stainless steel substrate, it is graphitized, that is, the sample is placed in a vacuum In a drying oven, treat at 100°C for 60 minutes.

Embodiment 2

[0023] Example 2: The preparation method of the anti-wear coating is as follows: immerse the stainless steel substrate in an acetone solution for 1 h; 98% concentrated sulfuric acid and 30% hydrogen peroxide solution are made into an oxidizing agent at a volume ratio of 2:1 to the substrate Carry out oxidation, wash and dry after reacting for 60 minutes; make a solution according to the ratio of aminosilane coupling agent (about 1% by volume fraction), acetone (about 80% by volume fraction), and water (about 19% by volume fraction), after fully stirring Immerse the stainless steel substrate in it and let it stand for 1h. Then soak it in 50ml of 0.6mg / ml graphene oxide solution. The solution casting process is kept at a temperature of 110°C. After the graphene oxide is coated on the stainless steel substrate, it is graphitized, that is, the sample is placed in a vacuum In a drying oven, treat at 120°C for 45min.

Embodiment 3

[0024] Example 3: The preparation method of the anti-wear coating is as follows: immerse the stainless steel substrate in an acetone solution for 1 h; 98% concentrated sulfuric acid and 30% hydrogen peroxide solution are made into an oxidizing agent at a volume ratio of 7:3 to the substrate Carry out oxidation, wash and dry after reacting for 30 minutes; make a solution according to the ratio of aminosilane coupling agent (about 1% by volume fraction), acetone (about 80% by volume fraction), and water (about 19% by volume fraction), after fully stirring Immerse the stainless steel substrate in it and let it stand for 1h. Then soak it in 50ml of 0.8mg / ml graphene oxide solution. The solution casting process is kept at a temperature of 110°C. After the graphene oxide is coated on the stainless steel substrate, it is graphitized, that is, the sample is placed in a vacuum In a drying oven, treat at 150°C for 30min.

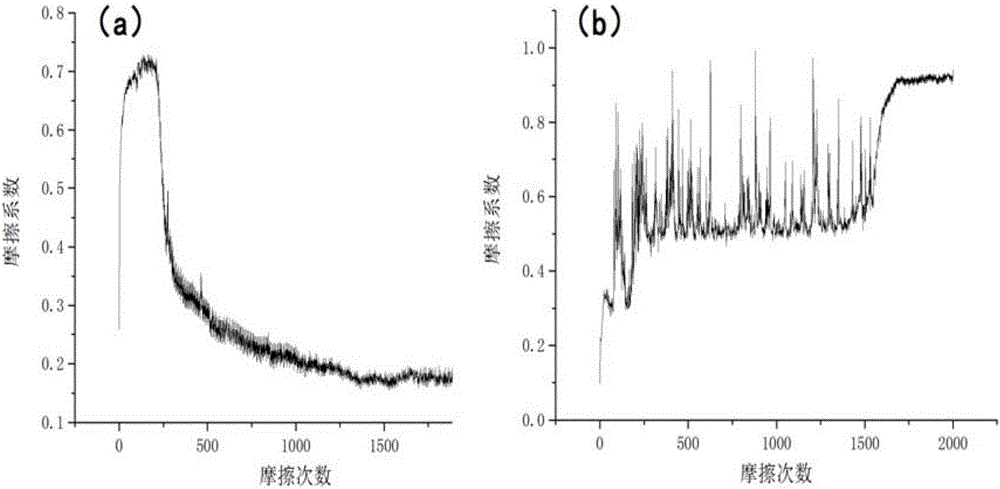

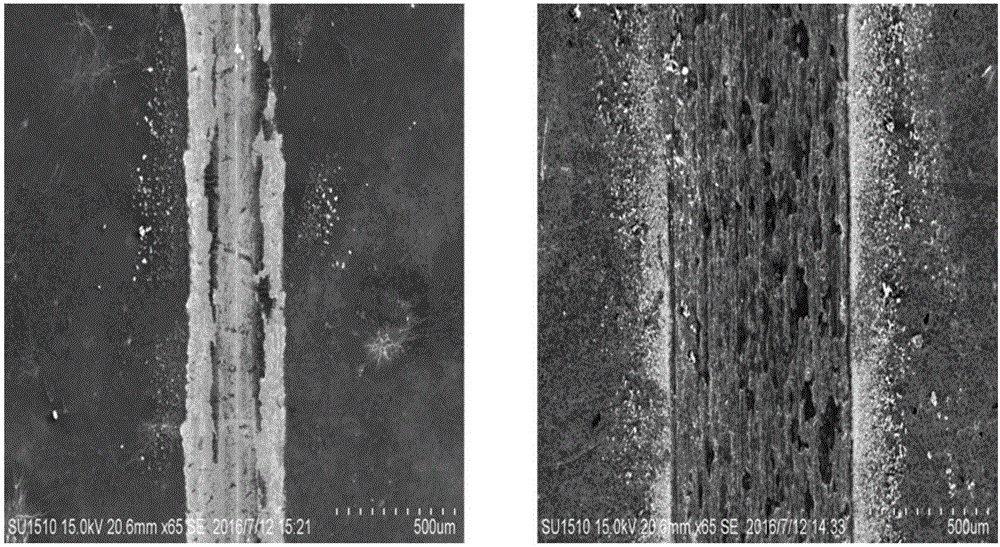

[0025] Finally, the CSM friction and wear tester was used to ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com