Method for preparing porous membrane by virtue of non-solvent induced phase method

A non-solvent, porous membrane technology, applied in the field of materials, to achieve the effect of shortening the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: A method for preparing a porous membrane by a non-solvent phase-induced method, using a non-solvent phase-induced method to dope submicron metal oxides to prepare hollow fiber, flat and tubular membranes with catalytic, hydrophilic, and antibacterial properties;

[0038] Prepare materials according to the following components (weight ratio):

[0039] PVDF resin content 30,

[0040] Submicron level metal oxide content 10,

[0041] Additive 80,

[0042] Organic salt dispersant 10,

[0043] Solvent 70.

[0044] The additive is one or more of polyvinylpyrrolidone, polyethylene glycol, polymethyl methacrylate and polyacrylonitrile with different molecular weights.

[0045]Submicron metal oxides have different particle sizes, in the range of 0.10-1000 microns, transition metals such as nickel oxides, iron oxides, aluminum oxides, magnesium oxides, copper oxides, and zinc oxides One or more of oxides and their oxyhydroxides.

[0046] One or a mixture of organi...

Embodiment 2

[0049] Embodiment 2: A method for preparing a porous membrane by a non-solvent phase-induced method, comprising the following steps;

[0050] Table 1:

[0051]

[0052] The specific implementation formula,

[0053] Do test 1, test 2, test 3, test 4, test 5, test 6 according to the formula in Table 1:

[0054] Test Characterization of Trials:

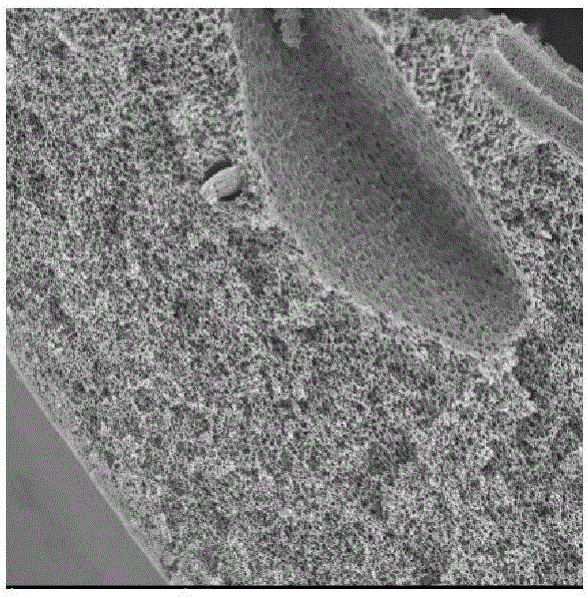

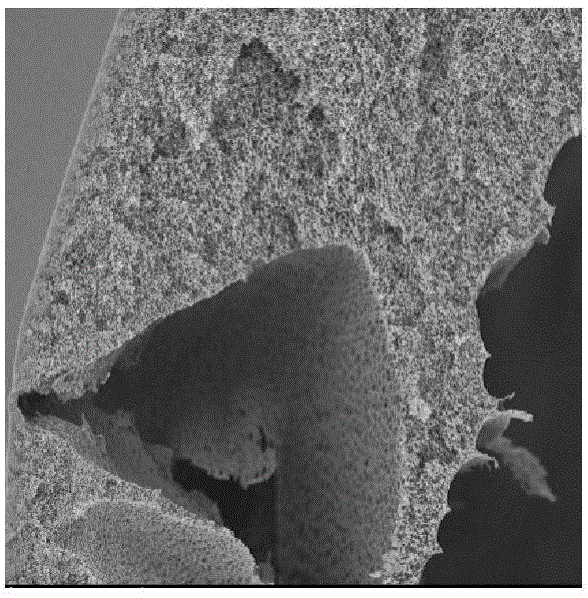

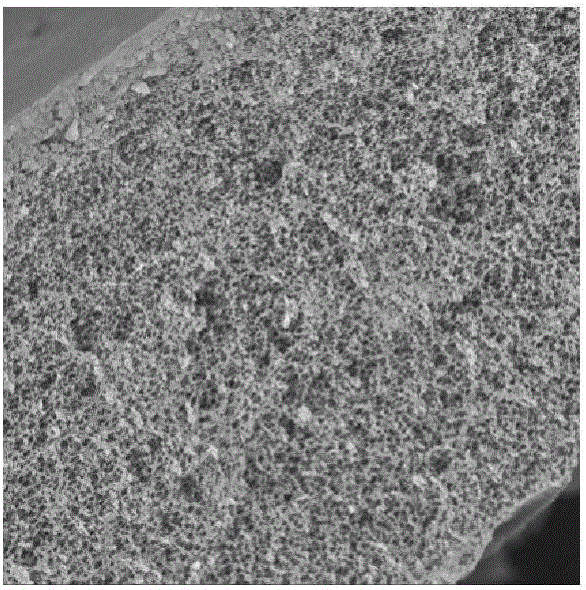

[0055] Electron microscope photos such as figure 1 (test 4), figure 2 (test 5), image 3 (Test 6) shows:

[0056] Test 1, Test 2, Test 3 and Test 4, Test 5, and Test 6 are comparative tests using nickel oxides, iron oxides, aluminum oxides, magnesium oxides, Copper oxide, zinc oxide and other transition metal oxides and one or more of their oxyhydroxides,

[0057] The test mainly illustrates the following rules:

[0058] 1. The transition metal oxides and their oxyhydroxides with larger particles are not easy to be lost, but the catalytic effect is poor;

[0059] 2. The antibacterial effect decreases with the increase of tra...

Embodiment 3

[0062] Example 3: A method for preparing a porous membrane by a non-solvent-induced phase method, using a non-solvent-induced phase method to dope submicron metal oxides to prepare hollow fiber, flat and tubular membranes with catalytic, hydrophilic, and antibacterial properties;

[0063] Prepare materials according to the following components (weight ratio):

[0064] Polyvinylidene fluoride resin content 15,

[0065] Submicron level metal oxide content 0.1,

[0066] additive 10,

[0067] Organic salt dispersant 0.1,

[0068] Solvent 40.

[0069] The additive is one or more of polyvinylpyrrolidone, polyethylene glycol, polymethyl methacrylate and polyacrylonitrile with different molecular weights.

[0070] Submicron metal oxides have different particle sizes, in the range of 0.10-1000 microns, transition metals such as nickel oxides, iron oxides, aluminum oxides, magnesium oxides, copper oxides, and zinc oxides One or more of oxides and their oxyhydroxides.

[0071] One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com