A method of preparing a macroporous/mesoporous stannic sulfide/titanium dioxide photocatalyst

A technology of titanium dioxide and photocatalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low photocatalytic activity and low quantum efficiency, and achieve simple operation, low cost, and synthesis The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation method of macroporous / mesoporous tin sulfide / titanium dioxide photocatalyst, comprises the following steps:

[0024] (1) 3.5 grams of butyl phthalate are first added to 2 milliliters of absolute ethanol;

[0025] (2) 1.75 grams of tin tetrachloride pentahydrate are joined in the above-mentioned (1) solution;

[0026] (3) 0.78 gram of sodium sulfide is dissolved in 100 milliliters of water;

[0027] (4) Add the above-mentioned (2) solution dropwise to the above-mentioned (3) solution, and then let stand for 24 hours;

[0028] (5) Transfer the precipitate and solution prepared in step (4) into a hydrothermal kettle, keep it warm at 180°C for 6 hours, clean the hydrothermal precipitate, and dry to obtain macroporous / mesoporous vulcanization Tin / TiO2 composite photocatalyst.

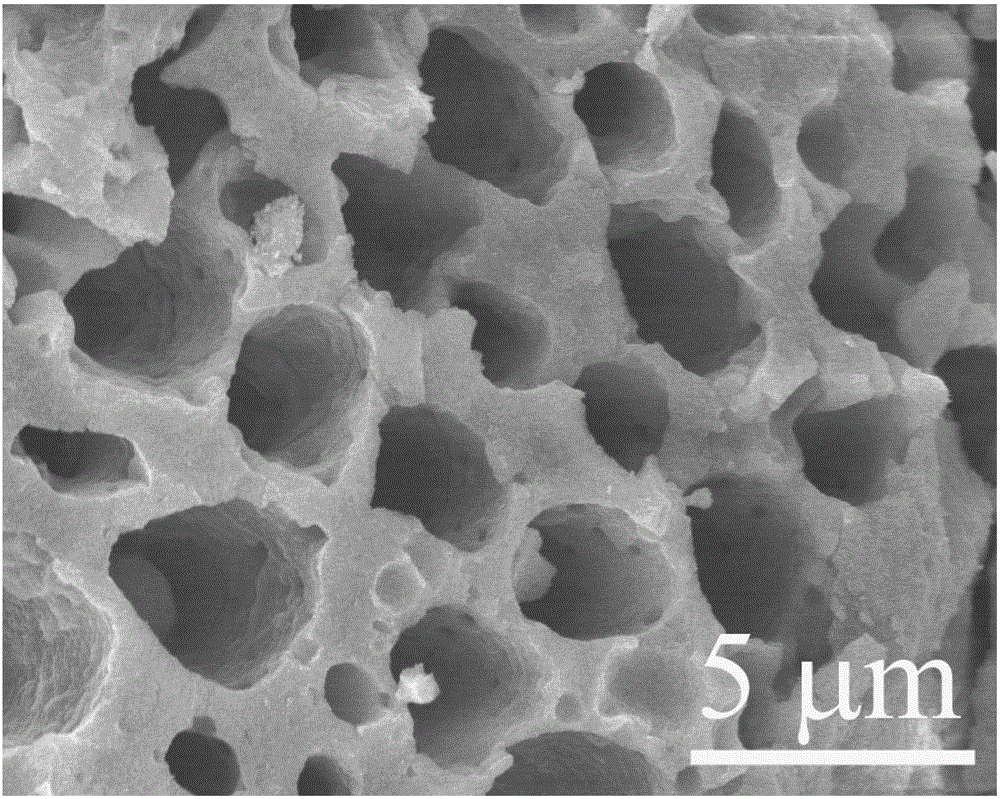

[0029] figure 1 It is a scanning electron microscope image of the macroporous / mesoporous tin sulfide / titanium dioxide composite photocatalyst prepared in this example. It can...

Embodiment 2

[0034] A kind of preparation method of macroporous / mesoporous tin sulfide / titanium dioxide photocatalyst, comprises the following steps:

[0035] (1) 5 grams of butyl phthalate are first added to 2 milliliters of absolute ethanol;

[0036] (2) 1.5 grams of tin tetrachloride pentahydrate are joined in the above-mentioned (1) solution;

[0037](3) 0.78 gram of sodium sulfide is dissolved in 100 milliliters of water;

[0038] (4) Add the above-mentioned (2) solution dropwise to the above-mentioned (3) solution, and then let stand for 24 hours;

[0039] (5) Transfer the precipitate and solution prepared in step (4) into a hydrothermal kettle, keep it warm at 180°C for 6 hours, clean the hydrothermal precipitate, and dry to obtain macroporous / mesoporous vulcanization Tin / TiO2 composite photocatalyst.

Embodiment 3

[0041] A kind of preparation method of macroporous / mesoporous tin sulfide / titanium dioxide photocatalyst, comprises the following steps:

[0042] (1) 3 grams of butyl phthalate are first added to 2 milliliters of absolute ethanol;

[0043] (2) 3 grams of tin tetrachloride pentahydrate are joined in the above-mentioned (1) solution;

[0044] (3) 0.78 gram of sodium sulfide is dissolved in 100 milliliters of water;

[0045] (4) Add the above-mentioned (2) solution dropwise to the above-mentioned (3) solution, and then let stand for 24 hours;

[0046] (5) Transfer the precipitate and solution prepared in step (4) into a hydrothermal kettle, keep it warm at 180°C for 6 hours, clean the hydrothermal precipitate, and dry to obtain macroporous / mesoporous vulcanization Tin / TiO2 composite photocatalyst.

[0047] Above-mentioned embodiment 2 and 3 in conjunction with embodiment 1 are the embodiment designed in order to examine the mass ratio of butyl phthalate and tin tetrachloride p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com