Preparation method and application of chemical-bonded thermally-conductive insulation composite filling material

A thermal insulation and composite filler technology, applied in chemical instruments and methods, heat exchange materials, etc., to achieve good thermal conductivity, good dispersion, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

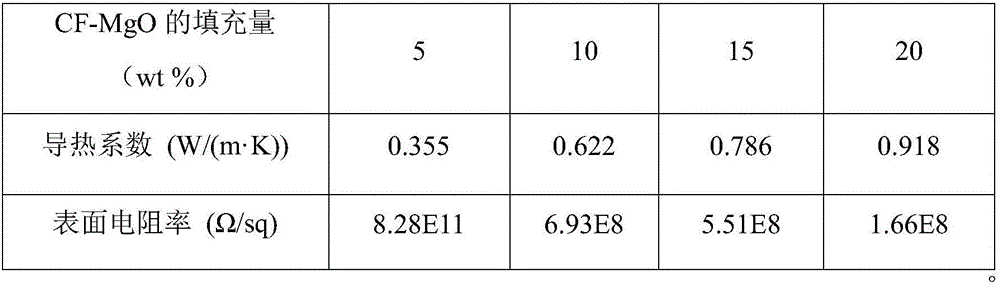

Examples

Embodiment 1

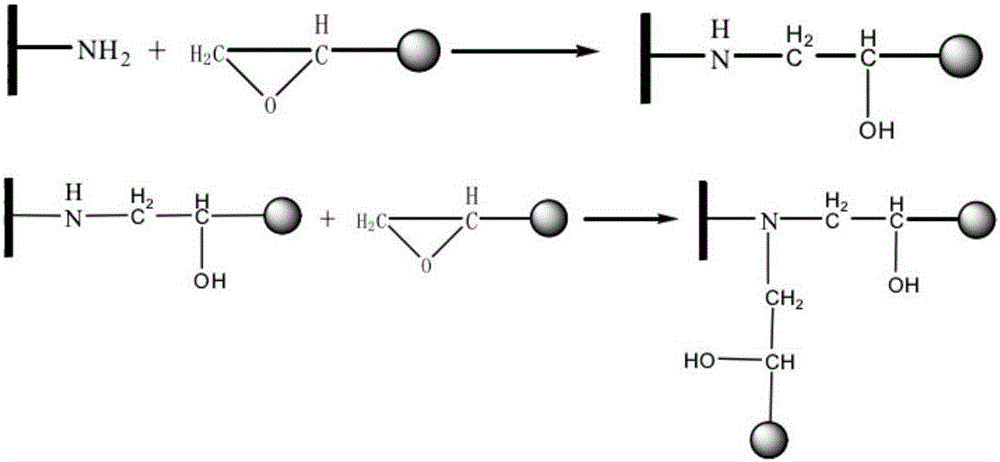

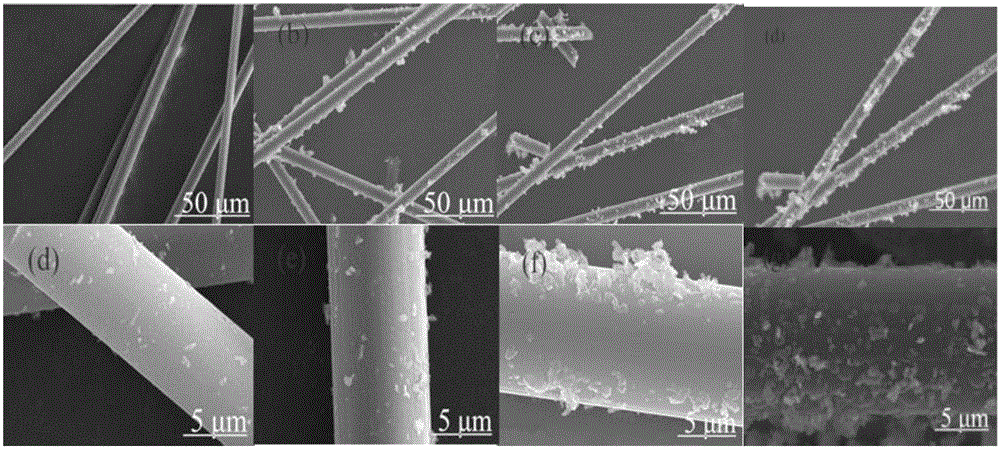

[0028] (1) Surface modification of chopped carbon fibers: first place the carbon fibers in concentrated acid for 6 hours, then clean them with deionized water, and dry them in vacuum; then prepare ethanol / Water mixed solution (volume ratio 5:1), and 5% chopped carbon fiber were reacted and refluxed at 100°C under nitrogen protection for 3 hours. After the reaction was completed, they were washed with ethanol and dried in vacuum to obtain chopped carbon fibers with amino-modified surfaces.

[0029] (2) Surface modification of magnesium oxide particles: Mix 2 g of dry magnesium oxide particles with 96 g of toluene, and ultrasonically disperse at room temperature for 30 minutes to obtain a suspension, then add 2 g of γ-glycidyl etheroxypropyl trimethoxysilane, and ℃ temperature reaction 10h. After the reaction is completed, suction filter while hot, wash, and vacuum-dry to obtain epoxy group-modified magnesium oxide particles.

[0030] (3) Grafting MgO particles on the surface ...

Embodiment 2

[0034] (1) Surface modification of carbon nanotubes: first place the carbon nanotubes in concentrated acid for 1 hour, wash them with deionized water, and dry them in vacuum; Ethanol / water mixed solution (volume ratio 5:1), reacted with 1% carbon nanotubes under nitrogen protection at 120° C. for 1 h, washed with ethanol after the reaction, and dried in vacuum to obtain amino-modified carbon nanotubes.

[0035] (2) Surface modification of zinc oxide particles: Mix 4 g of dry zinc oxide particles with 93 g of toluene and disperse ultrasonically at room temperature for 30 minutes to obtain a suspension, then add 3 g of γ-glycidyl etheroxypropyl trimethoxy silicon, and Reaction at high temperature for 6h. After the reaction is completed, suction filter while hot, wash, and vacuum-dry to obtain epoxy-modified zinc oxide particles.

[0036] (3) Zinc oxide particles grafted on the surface of carbon nanotubes: ultrasonically disperse 4 g of epoxy-modified zinc oxide particles in tol...

Embodiment 3

[0039] (1) Graphene surface modification: first place graphene in concentrated acid for 0.5h and then clean it with deionized water and dry it in vacuum; Ethanol / water mixed solution (volume ratio 5:1), reacted with 2% graphene at 80° C. under nitrogen protection and refluxed for 5 hours, washed with ethanol after the reaction, and dried in vacuum to obtain amino-modified graphene.

[0040] (2) Surface modification of alumina particles: Mix 3g of dried alumina particles with 93g of toluene (after ultrasonic dispersion at room temperature for 30min to obtain a suspension, then add 4g of γ-glycidyl etheroxypropyltrimethoxysilane, and The reaction was carried out at ℃ for 8 hours. After the reaction was completed, it was filtered while hot, washed, and dried in vacuum to obtain epoxy-modified alumina particles.

[0041] (3) Alumina particles grafted on the surface of graphene: 3g of epoxy-modified Al 2 o 3 The particles were ultrasonically dispersed in toluene for 30 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com