Technology for producing carbon fiber static smoking-control product

A production process, carbon fiber technology, applied in the direction of carbon fiber, fiber treatment, wear-resistant fiber, etc., can solve the problems that are not suitable for smokers, and achieve the effect of small thermal expansion coefficient, small heat transfer, and high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

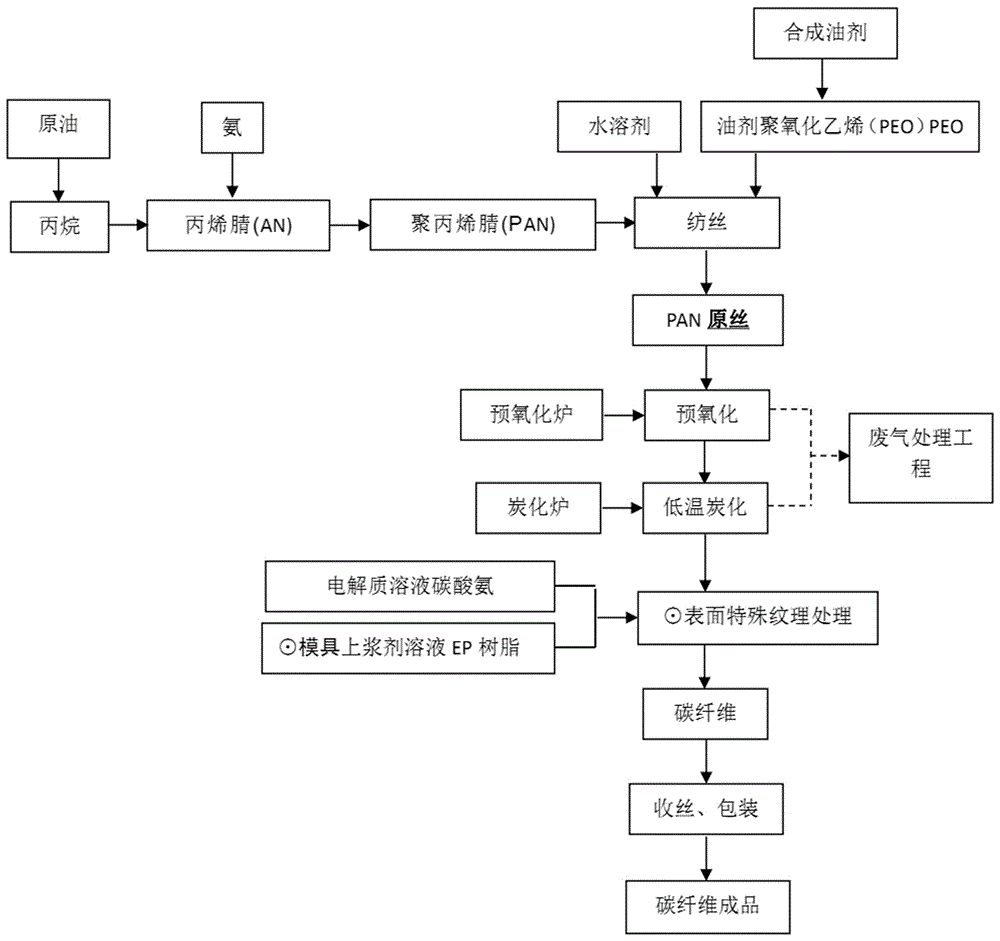

[0030] Such as figure 1 As shown, a production process of a carbon fiber electrostatic smoke control product comprises the following steps:

[0031] (1) Extract raw silk:

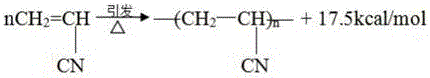

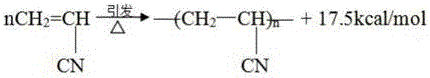

[0032] Extraction and selection of polyacrylonitrile precursors Under certain polymerization conditions, the double bonds of acrylonitrile (AN) are opened under the action of free radicals of the initiator, and are connected to each other into linear polyacrylonitrile (PAN) macromolecules Chain, while releasing heat of 17.5kcal / mol, namely:

[0033]

[0034] The resulting polyacrylonitrile (PAN) spinning solution can be obtained through spinning processes such as wet spinning or dry-jet wet spinning to obtain PAN precursors.

[0035] The basic characteristics of high-quality raw silk are: circular cross-section, smooth and non-destructive surface; fine crystal structure and high orie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com