Low-temperature lithium ion secondary battery

A secondary battery and lithium-ion technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as slow discharge speed, failure to meet customer needs, and failure to meet customer needs, and achieve good cycle performance and low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A low-temperature lithium-ion secondary battery includes a positive pole, a negative pole, a diaphragm placed between the positive pole and the negative pole, and an electrolyte.

[0023] Positive electrode: In this example, the positive electrode active material used in the positive electrode is a mixture of component A and component B, wherein component A is composed of 30% LiNiO 2 , 30%LiCoO 2 , 40%LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Mixed, component B is composed of 40%Li according to mass percentage 4 o 4 Ti, 20% Li 2 CrO 4 , 15% Li 3 V 2 (PO 4 ) 3 , 25% Li 2 o 3 Zr is mixed, and component B accounts for 12% of the mass of the entire positive electrode active material.

[0024] The outer surface of the positive electrode active material is also coated with a cladding layer, and the cladding layer is composed of 20 parts of MgO, 55 parts of Al in parts by mass. 2 o 3 and 25 V 2 o 5 The use of the cladding layer not only effectively prevents the short circui...

Embodiment 2

[0031] The difference between this example and Example 1 is that the negative electrode active material is also doped with fluoride carbon hexafluoride.

Embodiment 3

[0033] The difference between this example and Example 1 is that the component A in the positive electrode active material consists of 40% LiMnO 2 、60%LiNi 0.2 co 0.3 mn 0.5 o 2 mixed.

PUM

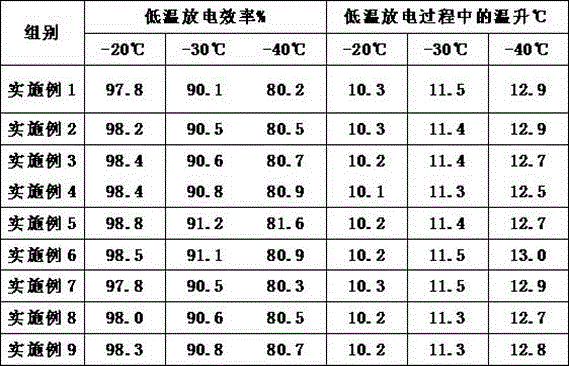

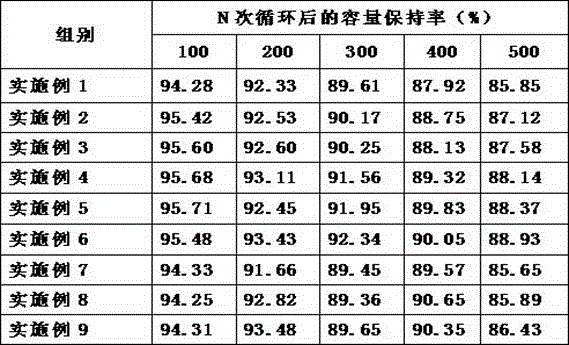

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com