Preparation method of supported ZnO nano array photocatalysts

A photocatalyst and nanoarray technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of limited practical application, difficult recovery, easy deactivation, etc. Recycling, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of supported ZnO nano-array photocatalyst, comprising the following steps:

[0033] (1) Treatment of the substrate

[0034] At room temperature, the substrate (ITO, metal sheet or glass slide) was ultrasonically treated in washing powder solution, acetone, isopropanol, and ethanol for 15-20 minutes, and then repeated 3 times with distilled water for 15-20 minutes. After washing, blow dry in nitrogen;

[0035] (2) Preparation of ZnO seed layer

[0036] Prepare the seed solution: dissolve polyvinylpyrrolidone in absolute ethanol, stir magnetically for 1 h to obtain solution A, wherein 0.1 g of polyvinylpyrrolidone is dissolved in 8 mL of absolute ethanol; dissolve zinc nitrate hexahydrate in distilled water to obtain solution B, Among them, dissolve 2.98g of zinc nitrate hexahydrate in 2 mL of distilled water; gradually add solution B to A, and the mass ratio of polyvinylpyrrolidone and zinc nitrate hexahydrate is 5:199, and then magnetically stir a...

Embodiment 1

[0041] (1) Treatment of the substrate

[0042] At room temperature, ultrasonically treat ITO in washing powder solution, acetone, isopropanol, and ethanol for 20 minutes, then repeat the ultrasonic treatment for 20 minutes with distilled water three times, wash it and dry it in nitrogen;

[0043] (2) Preparation of ZnO seed layer

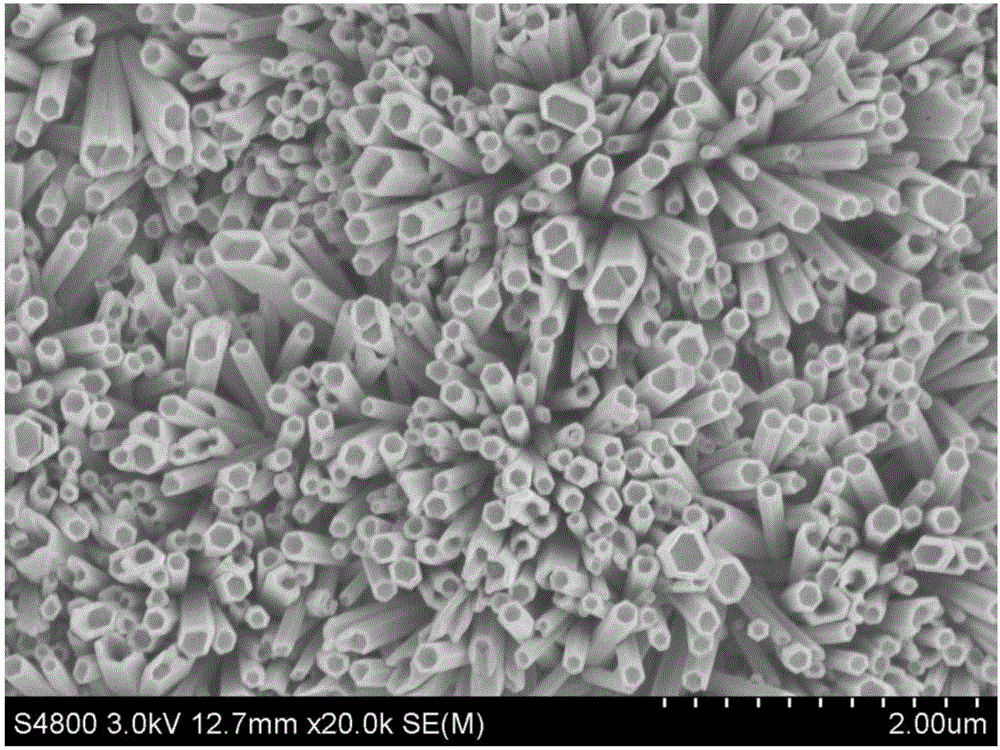

[0044] Preparation of seed solution: Dissolve 0.1g of polyvinylpyrrolidone in 8mL of absolute ethanol, stir magnetically for 1h to obtain solution A; dissolve 2.98g of zinc nitrate hexahydrate in 2mL of distilled water to obtain solution B; gradually add solution B to A , and then magnetically stirred at room temperature for 8 hours to obtain the seed solution, and then left to age for more than 48 hours. The substrate treated in step (1) was immersed in the seed solution to pull the coating film at a uniform speed. After the film was coated, the substrate was put into the muffle furnace , heating up to 400° and calcining for 60 minutes to obtain a...

Embodiment 2

[0050] (1) Treatment of the substrate

[0051] At room temperature, ultrasonically treat ITO in washing powder solution, acetone, isopropanol, and ethanol for 15 minutes, then repeat the ultrasonic treatment for 15 minutes with distilled water three times, wash it and dry it in nitrogen;

[0052] (2) Preparation of ZnO seed layer

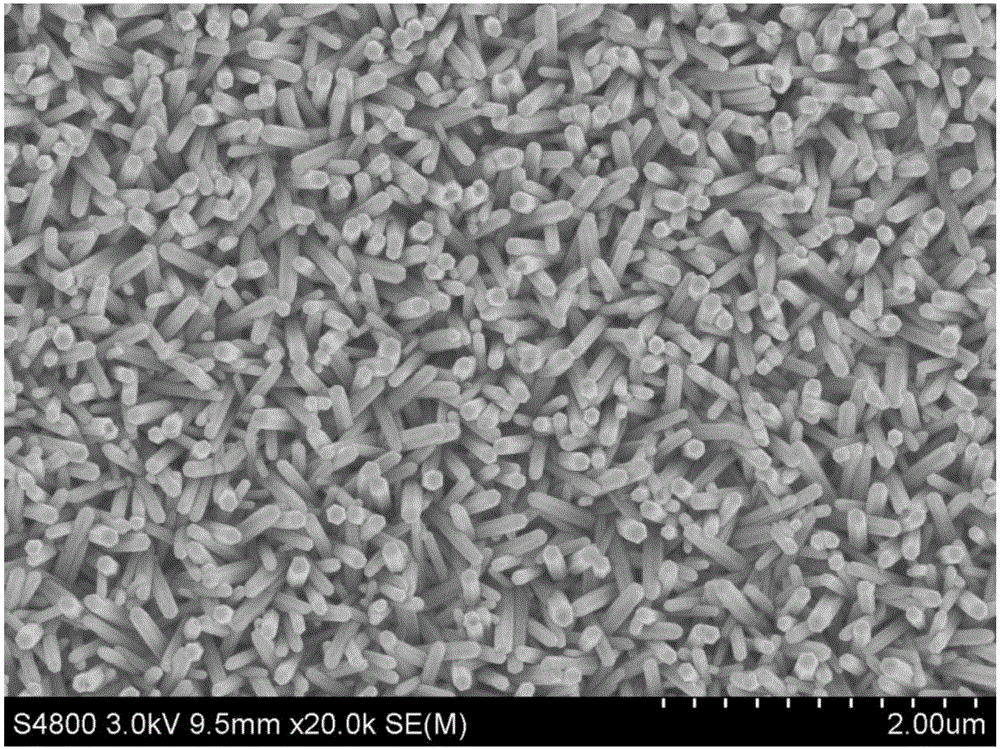

[0053] Preparation of seed solution: Dissolve 0.1g of polyvinylpyrrolidone in 8mL of absolute ethanol, stir magnetically for 1h to obtain solution A; dissolve 2.98g of zinc nitrate hexahydrate in 2mL of distilled water to obtain solution B; gradually add solution B to A , and then magnetically stirred at room temperature for 10 hours to obtain the seed solution, and then left to age for more than 48 hours, the substrate treated in step (1) was immersed in the seed solution to pull the coating film at a uniform speed, and the substrate was put into the muffle furnace after coating , heating up to 400° and calcining for 60 minutes to obtain a substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com