Method for producing potassium dihydrogen phosphate by refining by-product washing water with wet-process phosphoric acid

A technology of potassium dihydrogen phosphate and wet-process phosphoric acid, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high raw material cost and complicated process flow, and achieve improved recovery rate, simplified process flow, and high-efficiency The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

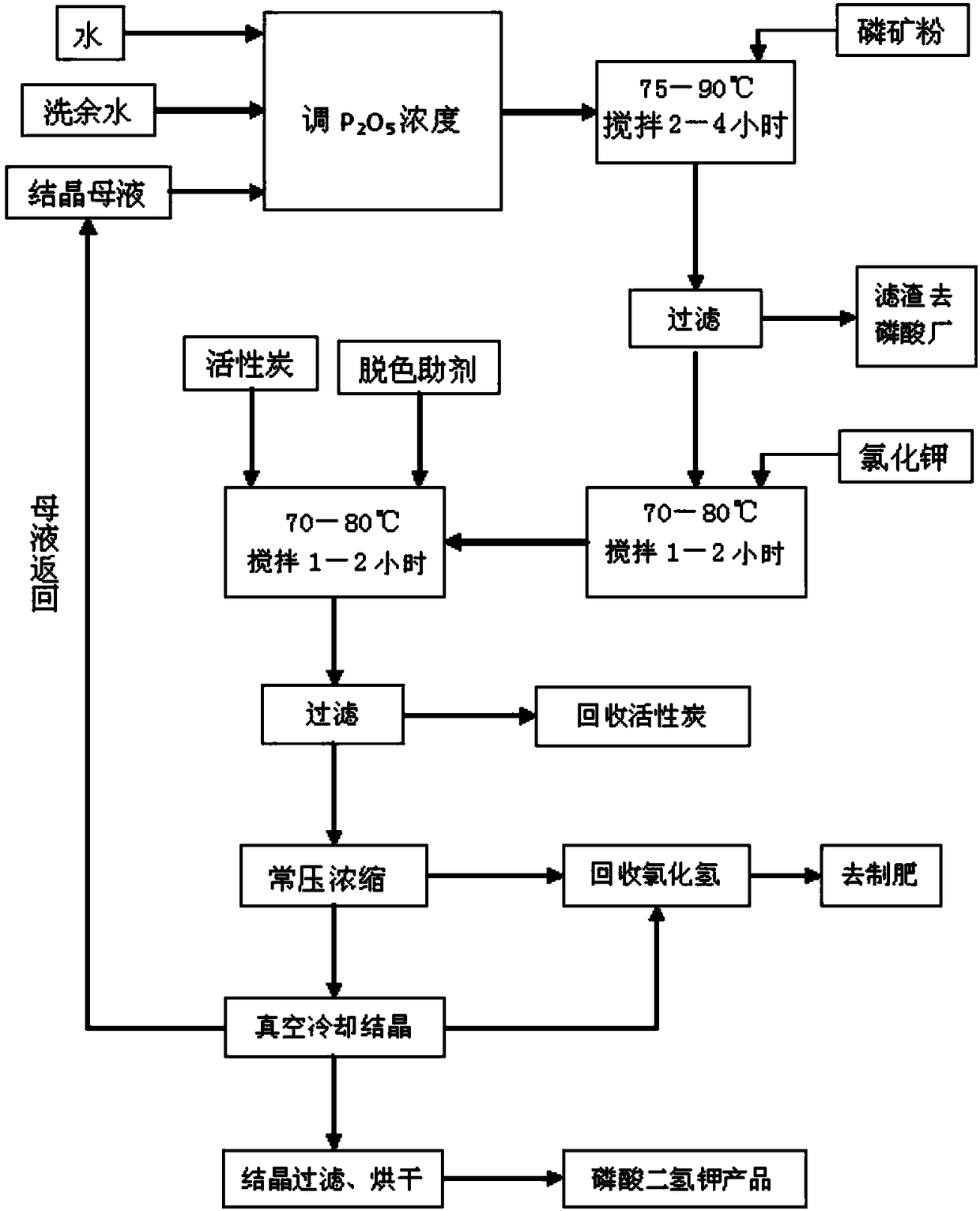

[0108] see Figure 1 to Figure 14 , a method for producing potassium dihydrogen phosphate by using wet-process phosphoric acid refining by-product wash water, comprising the following steps in turn:

[0109] Acid adjustment process: firstly mix the washing water and water evenly to obtain a mixed solution, and the P in the mixed solution 2 o 5 The mass percent concentration is 18%; the product obtained after the potassium salt washing water configured by solvent extraction refining wet-process phosphoric acid from the solvent extraction process participates in the reaction, and the raffinate includes P 2 o 5 with sulfate, P 2 o 5 The mass percentage concentration is 35%, and the content of sulfate radical is 35g / L;

[0110] Desulfurization process: first add phosphate rock powder or calcium carbonate or barium carbonate to the above mixed solution according to 85% of the stoichiometric amount of sulfate in the mixed solution for desulfurization. The desulfurization time i...

Embodiment 2

[0116] Basic content is the same as embodiment 1, the difference is:

[0117] Acid adjustment process: P in the mixture 2 o 5 The mass percentage concentration is 22%; P in the washing water 2 o 5 The mass percentage concentration is 45%, and the content of sulfate radical is 65g / L;

[0118] Desulfurization process: add phosphate rock powder or calcium carbonate or barium carbonate according to 50% of the stoichiometric amount of sulfate radicals in the mixture for desulfurization;

[0119] Mixing process: add potassium chloride according to 95% of the stoichiometric amount of phosphoric acid in the filtrate;

[0120] Decolorization and impurity removal process: the addition of activated carbon is 5‰ of the solution volume, and the addition of decolorization aid is 1‰ of the solution volume;

[0121] Atmospheric pressure concentration process: the temperature of atmospheric concentration is 140°C, and the specific gravity after atmospheric concentration is 1.35;

[0122]...

Embodiment 3

[0124] Basic content is the same as embodiment 1, the difference is:

[0125] Acid adjustment process: P in the mixture 2 o 5 The mass percentage concentration is 20%; P in the washing water 2 o 5The mass percent concentration is 40%, and the sulfate radical content is 50g / L;

[0126] Desulfurization process: add phosphate rock powder or calcium carbonate or barium carbonate according to 68% of the stoichiometric amount of sulfate radical in the mixture for desulfurization;

[0127] Mixing process: add potassium chloride according to 90% of the stoichiometric amount of phosphoric acid in the filtrate;

[0128] Decolorization and impurity removal process: the amount of activated carbon added is 2‰ of the solution volume, and the amount of decolorization aid is 3‰ of the solution volume;

[0129] Atmospheric pressure concentration process: the temperature of atmospheric concentration is 155°C, and the specific gravity after atmospheric concentration is 1.33;

[0130] Cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com