Production process of low-chloride amido-trimethylene phosphonic acid (ATMP)

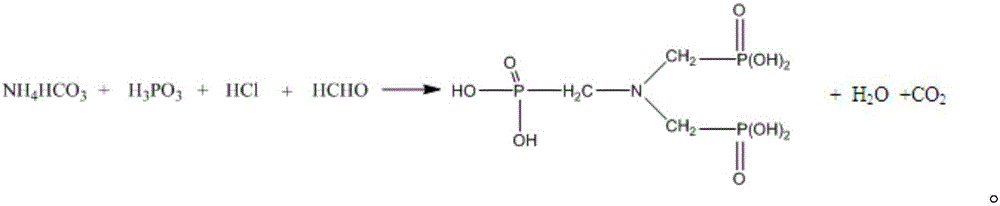

A technology of low-chlorine amino trimethylene phosphonic acid and chloroamino trimethylene phosphonic acid is applied in the field of production technology of amino trimethylene phosphonic acid, which can solve the problem of high chloride ions, and achieve the effects of reducing content and expanding application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

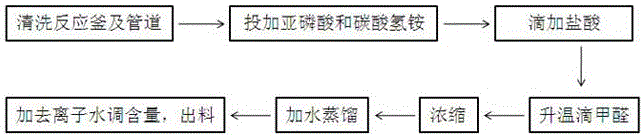

[0024] A production process of low-chlorine amino trimethylene phosphonic acid, the specific steps are: cleaning the reactor and related equipment, closing the bottom valve of the reactor; pumping 2200 kilograms of 80% liquid phosphorous acid into the reactor. Open the solid feeding port, add 600 kg of food-grade ammonium bicarbonate, after adding, open the condenser, stir, and heat up. When the temperature rises to 40°C, add 600 kg of hydrochloric acid dropwise, and the dropwise addition process controls the micro-negative pressure state in the reactor to be -0.02~-0.01mpa, and the dropwise addition time is 4 hours; after the dropwise addition, continue to heat up to 80°C, Start to drop 3500 kg of formaldehyde solution, control the temperature of the feed liquid in the kettle between 85-95°C during the dropping process, and control the dropping time at 4 hours; Warm concentration until the feed liquid is concentrated to a viscous state, and the concentration time is controlle...

Embodiment 2

[0026] A production process of low-chlorine amino trimethylene phosphonic acid, the specific steps are: cleaning the reaction kettle and related equipment, closing the bottom valve of the reaction kettle; pumping 2500 kilograms of 80% liquid phosphorous acid into the reaction kettle. Open the solid feeding port, add 700 kg of food-grade ammonium bicarbonate, after the addition is complete, open the condenser, stir, and heat up. When the temperature rises to 50°C, add 500 kg of hydrochloric acid dropwise, and the dropwise addition process controls the micro-negative pressure state in the reactor to be -0.02~-0.01mpa, and the dropping time is 4.5 hours; after the dropwise addition, continue to heat up to 90°C, Start to drop 3200 kg of formaldehyde solution, control the temperature of the feed liquid in the kettle between 95-105°C during the dropping process, and control the dropping time at 4 hours; Warm concentration until the material liquid is concentrated to a viscous state,...

Embodiment 3

[0028] A production process of low-chlorine amino trimethylene phosphonic acid comprises the following steps: cleaning the reactor and related equipment, closing the bottom valve of the reactor; pumping 3000 kilograms of 80% liquid phosphorous acid into the reactor. Open the solid feeding port, add 800 kg of food-grade ammonium bicarbonate, after adding, open the condenser, stir, and heat up. When the temperature rises to 50°C, add 400 kg of hydrochloric acid dropwise, the dropwise addition process controls the micro-negative pressure state in the reactor to be -0.02~-0.01mpa, and the dropwise addition time is 4.5 hours; after the dropwise addition, continue to heat up to 100°C, Start to drop 3000 kg of formaldehyde solution, control the temperature of the feed liquid in the kettle between 95-105°C during the dropping process, and control the dropping time at 4 hours; Warm concentration until the material liquid is concentrated to a viscous state, and the concentration time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com